Iron ore jaw crusher

The iron ore jaw crusher features a simple structure, a high crushing ratio, stable operation, and easy adjustment. Small units cost around US$7,000, while large units range from US$120,000 to US$300,000. Feed size: ≤1200mm Processing capacity: 3-1000 tons/hour Motor power: 15-400kW Discharge adjustment range: 18-350mm

What is an iron ore jaw crusher?

In an iron ore production line, an Iron ore jaw crusher performs coarse and secondary crushing, thereby crushing the harder iron ore. The equipment typically handles feed sizes between 120-1500mm, discharge sizes between 10-360mm, and a processing capacity of 1-2200 tons/hour. Iron ore typically has a hardness between 5 and 6 on the Mohs scale and is quite brittle. Key components, such as the jaw plates, are often made of high-manganese steel to cope with the ore's hardness and abrasiveness. It offers a simple structure, a high crushing ratio, stable operation, and easy adjustment. Small units cost around US$7,000, while larger units range from US$120,000 to US$300,000.

How is iron ore crushed by an iron ore jaw crusher?

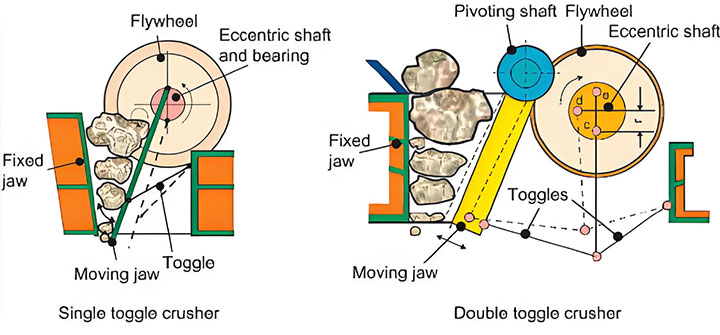

The iron ore jaw crusher primarily utilizes the "compression crushing" principle, operating in the feeding, crushing, and discharge stages. The process consists of the following three steps:

Feeding Stage: Iron ore enters the crushing chamber through the feed inlet. Inside the chamber, a fixed jaw plate (fixed jaw) and a movable jaw plate (moving jaw) form a V-shaped space, and the ore falls under gravity between the two jaw plates.

Crushing Stage: The motor drives the eccentric shaft to rotate, driving the movable jaw to oscillate periodically. When approaching the fixed jaw, the two jaw plates squeeze and split the iron ore, causing it to break due to the pressure exceeding its compressive strength. When moving away from the fixed jaw, the crushed ore falls with the swing of the movable jaw.

Discharging Stage: The crushed ore continues to fall to the bottom of the crushing chamber, where it is further refined by the repeated swinging of the movable jaw. Ore that meets the required particle size is discharged from the discharge port, while any that does not meet the standard remains in the chamber for further crushing.

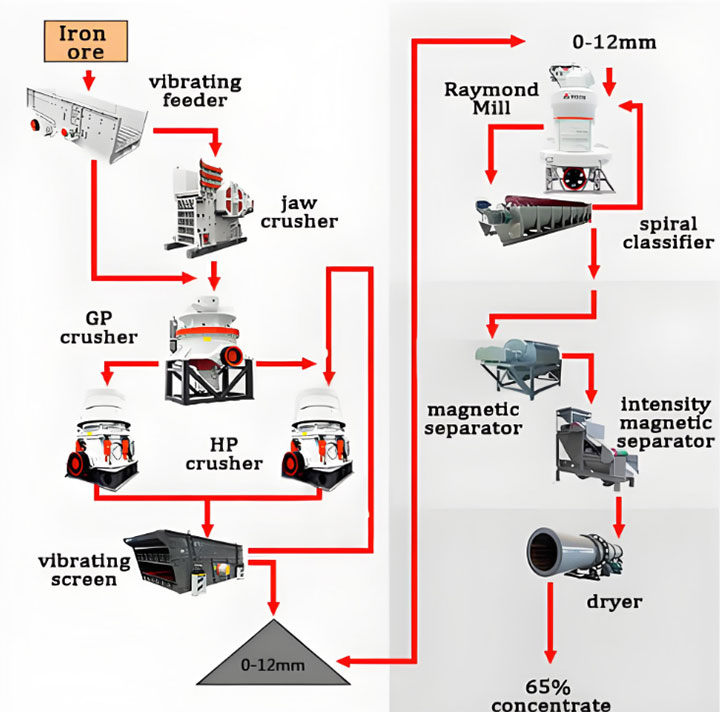

Production Flowchart

Advantages of the Iron Ore Jaw Crusher in Iron Ore Processing

The Iron Ore Jaw Crusher features an optimized chamber shape tailored to the high hardness of iron ore. It can quickly crush large lumps of iron ore (up to 1500mm in diameter) to a suitable particle size, with a processing capacity of 10-2000 tons/hour, meeting the pre-crushing needs of mineral processing plants of varying sizes. The movable and fixed jaw liners are made of high-manganese steel or wear-resistant alloy, offering impact and wear resistance, and are resistant to impurities such as quartz. This reduces wear, extends component replacement cycles, and lowers maintenance costs. Furthermore, the Iron Ore Jaw Crusher features a compact structure, few transmission components, and balanced force distribution, resulting in minimal malfunctions and vibration during continuous operation. It also requires minimal plant foundations and is easy to install and commission. The resulting iron ore is uniform in particle size with minimal over-crushing, reducing subsequent grinding energy and media consumption, improving beneficiation economics. It is particularly suitable for pre-processing magnetite and hematite.

Iron Ore Jaw Crusher Technical Parameters

| Model | Inlet size (mm) | Max feeding size (mm) | Discharge opening rang (mm) | Processing capacity (m³/h) | Power (kW) | Weight (t) |

| PE-150x250 | 150x 250 | 125 | 10~40 | 1~3 | 7.5 | 13 |

| PE-250x400 | 250x400 | 210 | 20~60 | 3~13 | 15 | 2.8 |

| PE-400x600 | 400x 600 | 340 | 40~100 | 10~35 | 30 | 6.5 |

| PE-500x750 | 500x750 | 425 | 50~100 | 25~60 | 55 | 10.6 |

| PE-600x 900 | 600x 900 | 500 | 65~180 | 30~85 | 55~75 | 15.5 |

| PE-750x1060 | 750x1060 | 630 | 80~180 | 72~150 | 90~110 | 28 |

| PE-900x1200 | 900x1200 | 780 | 95~255 | 100~240 | 110~132 | 49 |

| PE-1000x1200 | 1000x1200 | 850 | 195~280 | 190~275 | 110~132 | 51 |

| PE-1200x1500 | 1200x1500 | 1020 | 150~300 | 250~500 | 160 | 100.9 |

| PEX-150x500 | 150x500 | 120 | 10~40 | 3~15 | 11 | 2.5 |

| PEX-150x 750 | 150x 750 | 120 | 10~40 | 5~16 | 18.5 | 35 |

| PEX-250x 750 | 250x750 | 210 | 15~50 | 8~35 | 30 | 5.8 |

| PEX-250x1000 | 250x1000 | 210 | 15~50 | 13~45 | 37 | 6.4 |

| PEX-250 x1200 | 250x1200 | 210 | 15~50 | 13~50 | 37 | 7.7 |

| PEX-300x1300 | 300x1300 | 250 | 15~50 | 20~60 | 75 | 11 |

What are the three types of Iron Ore Jaw Crusher?

Iron ore jaw crushers come in three common types: simple swing jaw crushers are suitable for coarse crushing of iron ore; compound swing jaw crushers can be used for coarse or secondary crushing; and hydraulic jaw crushers are suitable for iron ore crushing lines requiring a high degree of automation.

The simple swing jaw crusher uses a suspension shaft as the fixed fulcrum for the movable jaw, which swings in a simple arc. There is no forced propulsion mechanism at the bottom, resulting in a regular crushing chamber. An eccentric shaft drives a connecting rod, causing the movable jaw to swing slightly around the suspension shaft. This periodic movement of the movable jaw and fixed jaw toward and away from each other compresses the ore, with the upper portion of the movable jaw swinging slightly less and the lower portion swinging more, making it suitable for coarse crushing. This type of crusher has a simple and easy-to-maintain structure, a deep crushing chamber with minimal upper and lower width differences, and stable processing capacity. Typical single-unit output is 50-500 tons/hour, with minimal overcrushing. It is primarily used for initial coarse crushing and pretreatment of medium-hard materials such as iron ore and granite in mining.

The compound-swing iron ore jaw crusher's movable jaw is directly connected to the eccentric shaft, eliminating the need for a separate linkage. It performs a combined "swing + rotation" motion around the suspension shaft and eccentric shaft, resulting in a greater stroke in the lower portion of the crushing chamber. As the motor drives the eccentric shaft to rotate, the movable jaw generates multi-directional forces, which not only compresses but also shears and grinds the ore. This results in high crushing efficiency, with a single-unit output of 80-800 tons/hour. The lower portion of the movable jaw swings much more dramatically than the upper portion, facilitating discharge. It also offers a high crushing ratio and 15%-30% higher production efficiency than the simple-swing iron ore jaw crusher. Its compact structure and minimal footprint eliminate the need for separate linkages and toggle plate adjustments. It is suitable for coarse or medium crushing of medium-hard materials such as iron ore and limestone, and is used in small and medium-sized mines and construction aggregate processing.

Hydraulic iron ore jaw crushers are often based on the compound-swing model, with an additional hydraulic adjustment system and protection devices. The hydraulic cylinder precisely controls the discharge opening size and provides automatic overload protection. Its core still relies on the extrusion crushing of the movable and fixed jaws, but the discharge size can be adjusted without manual disassembly. Fine adjustments can be made by hydraulically pushing wedges or driving the movable jaw. The hydraulic system automatically relieves pressure to protect the machine when encountering unbreakable debris. This type of crusher offers convenient operation, high adjustment efficiency, and a low failure rate. It is suitable for highly automated production lines, with a single unit output of 100-1200 tons/hour. It can crush materials of various hardnesses from coarse to medium crushing. It is particularly suitable for large-scale mining and metallurgical industries that require high crushing stability and automation. It can process metal ores such as iron ore and copper ore, as well as non-metallic ores.

Iron Ore Jaw Crusher Price

Small iron ore jaw crushers have feed openings smaller than 400 x 600 mm and cost approximately $10,000-20,000 USD, with a capacity of several to tens of tons per hour. Medium-sized equipment ranges from 600 x 900 mm to 750 x 1060 mm and costs $45,000-120,000 USD, with a capacity of 100-300 tons per hour. Large equipment, larger than 900 x 1200 mm, costs $150,000-$500,000 USD and upwards, is used in large mines, has a capacity exceeding 500 tons per hour, and utilizes wear-resistant materials and intelligent control systems.

Iron Ore Jaw Crusher Solutions

What are the uses of the crushed iron ore processed by an iron ore jaw crusher?

Crushed iron ore after being crushed by an iron ore jaw crusher is primarily used as a core raw material for steel production. After beneficiation and purification, it is mixed with coke, limestone, and other materials and fed into blast furnaces to be smelted into pig iron. This iron ore is then processed into steel for use in construction, automobiles, machinery, and other fields. Some of this iron ore can also be used as a raw material for direct reduced iron (DRI) or molten reduced iron (SRI) to meet the needs of specialty steel production, or as a counterweight for heavy machinery, concrete ballast, and as an additive for refractory materials in industrial furnaces.

Iron Ore Jaw Crusher Applications

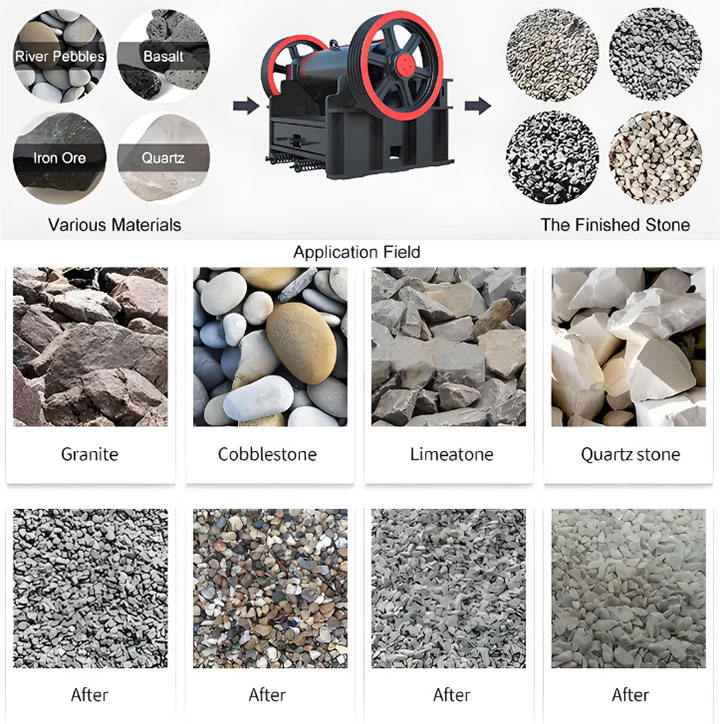

In addition to iron ore, the iron ore jaw crusher can also be used for the following materials. The appropriate model can be selected based on the specific characteristics of the material.