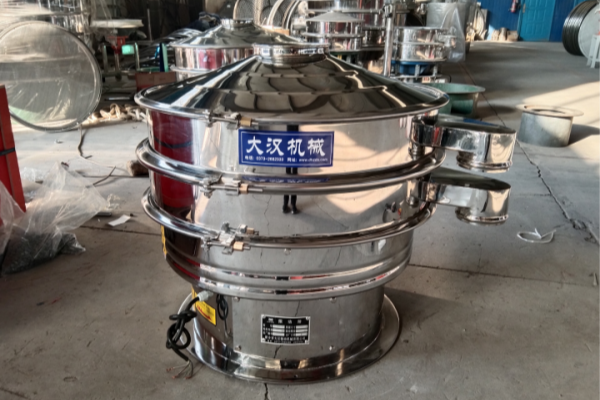

Gravel Sifting Machine

Gravel Sifting Machine generally costs between $500.00-$6700.00/Set.There are numerous models available, usually classified by processing capacity (such as 5-20 tons/hour, 20-50 tons/hour, 50-100 tons/hour) and screen aperture (like 0.5mm, 5mm, 20mm).

Mesh number: 400 mesh

Feeding particle size: 0.074-10mm

layer:1-6 layers

Capacity:0.12-30 t/h

Motor Power:2*(0.4-3.7)kw

What is Gravel Sifting Machine?

Gravel Sifting Machine is used to grade and remove impurities of 0.5-10mm fine gravel, 5-30mm medium gravel and 20-100mm coarse gravel. It uses a vibrating motor to drive the screen surface to move linearly. Its function is to accurately separate gravel into 2-6 different specifications according to particle size through screens of different mesh sizes or remove impurities or foreign matter to improve the quality and purity of gravel.

Gravel Sifting Machine is suitable for screening coarse-grained materials such as gravel, sand, pebbles, slag, etc., with a processing capacity of 0.5-30 tons/hour; in terms of material selection, the screen frame is made of Q235 carbon steel or 304 stainless steel, and the screen is available in manganese steel, polyurethane or perforated plate, which is wear-resistant and corrosion-resistant, and can meet the different working conditions of gravel.

What are the advantages of Gravel Sifting Machine?

Choosing our Gravel Sifting Machine, you will get the following significant advantages that are closely aligned with the practical needs of gravel processing, ensuring efficient and reliable operation in various scenarios:

High-efficiency grading ability: The linear vibration trajectory makes the gravel evenly distributed on the screen surface and move forward quickly, and the screening efficiency is 15-20% higher than that of traditional equipment.

Precise particle size control: The gravel classification point can be precisely controlled, with a variety of specifications from 0.5mm to 100mm available to meet the requirements of different industry standards

Large processing capacity design: The processing capacity of a single machine can reach 30 tons/hour, which is particularly suitable for the continuous operation requirements of large gravel production lines

Low maintenance cost: The use of high wear-resistant screens and reinforced steel structures extends the life of key components by 30%, reducing downtime and maintenance time

What is the principle of Gravel Sifting Machine?

When the Gravel Sifting Machine is working, the gravel enters the screen from the feed port. Under the linear vibration generated by the synchronous reverse rotation of the dual motors, the gravel is thrown up on the screen surface and moves forward in a linear manner in a jumping manner. During this screening process, gravel particles smaller than the screen size fall through the screen into the lower screen surface or are directly discharged, and gravel particles larger than the screen size continue to move forward along the screen surface until they are discharged from the discharge port.

Gravel Sifting Machine parameters

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

What is the use of Gravel Sifting Machine?

Gravel Sifting Machine is suitable for screening gravel with a particle size of 0.5mm~100mm, and the corresponding mesh size is about 5 mesh~30 mesh (the specific size varies slightly due to the density and shape of the material).

Coarse screen (5~10 mesh): handles large-particle gravel of 20~100mm, such as building aggregates, river pebbles, etc.

Medium screen (10~20 mesh): classifies medium gravel of 5~20mm, which is used for concrete batching or roadbed paving.

Fine screen (20~30 mesh): screens fine gravel or sand of 0.5~5mm, which is suitable for fine building materials or water treatment filter materials.

What are the customer cases of Gravel Sifting Machine?

| Case name | Equipment model and configuration | Processing materials | Screening specifications | Processing capacity | Project effect |

| Gravel production line of a large building materials group in Africa | DZSF2460 linear screening machine (3-layer screen) | Granite crushed and mixed with gravel | 0-5mm, 5-20mm, 20-40mm | 50 tons/hour | Screening efficiency is over 95%, replacing the original 2 circular vibrating screens, saving 25% of electricity consumption |

| Ballast production plant for a high-speed railway project in Indonesia | DZSF3072 linear screening machine (2-layer screen) | Basalt crushed material | 30-50mm (upper layer), 50-70mm (lower layer) | 40 tons/hour | Fully meet the requirements of high-speed railway ballast standards, the equipment has been running continuously for 2 years without major repairs |

| Aggregate system of a concrete company in Southeast Asia | DZSF1530 linear screen (3-layer screen) | River pebble crushing material | 0-5mm, 5-10mm, 10-20mm | 20 tons/hour | Accurate aggregate grading, significantly improved concrete quality stability |

| A road building materials recycling project in China | DZSF1848 linear screen (2-layer screen) | Building demolition recycled aggregate | 0-10mm, 10-30mm | 30 tons/hour | Realize resource utilization of more than 90% of construction waste, with significant environmental benefits |

Our factory's Gravel Sifting Machine lineup is comprehensive, including banana screens, mining vibrating screens, industrial screens, and circular vibrating screens. Banana screens are ideal for handling large quantities of materials with high efficiency, suitable for coarse screening in mining and aggregate production. Mining vibrating screens excel in tough mining environments, with robust structures to withstand heavy loads and prolonged use. Industrial screens are versatile, adapting to various industrial scenarios like building materials and recycling. Circular vibrating screens offer stable performance, ensuring precise grading for different gravel particle sizes.We also provide customized services. Based on your specific needs such as processing capacity, material characteristics, and screening specifications, we can tailor the right Gravel Sifting Machine solution to meet your project requirements effectively.

Powder Sieve Machine

Powder Sieve Machine  Ultrasonic Sieve

Ultrasonic Sieve Vibro Sifters For Sieving Molybdenum

Vibro Sifters For Sieving Molybdenum Salt Classifying With Vibro Sifter

Salt Classifying With Vibro Sifter