Salt Classifying with Vibro Sifter

Salt classifying with vibro sifter is usually priced between $500.00 and $4,500.00 per set. There are many models available, typically classified by classifying grades (e.g., 2-6 grades), processing capacity, and applicable salt types.

Diameter:400mm(15"), 600mm(24"), 800mm(31"), 1000mm(39"), 1200mm(47"), 1500mm(59"), 1800mm(70"), 2000mm(78")

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Screen frame: 1-5 layers

Material: 0.25Kw to 2.2Kw or customized

Motor power: 220V/0.5–1.5kW

What is salt classifying with vibro sifter?

Salt Classifying with Vibro Sifter is the process of separating salt crystals into distinct particle size fractions using a specialized vibrating screening machine. The salt classifying with vibro sifteroperation feeds salt onto inclined mesh screens within the sifter. High-frequency vibrations stratify the material, allowing smaller particles to pass through the screen apertures (undersize), while larger particles travel across the screen surface to discharge separately (oversize). This efficient Vibro Sifterensures consistent particle size distribution, removes lumps or oversized crystals, and enhances product quality for applications requiring specific salt granulation. It's vital for producing uniform table salt, industrial salt, and meeting precise grading standards.

Whats the coreAdvantages of Usingsalt classifying with vibro sifter?

Completely upgraded accuracy, life, blockage prevention and efficiency

Classification accuracy > 98%:Three - dimensional spiral vibration allows for full stratification of salt particles - ensuring fine and uniform taste of edible salt and increasing the chemical reaction rate of industrial salt.

Corrosion - resistant and long - lasting:316L stainless steel + Teflon - coated screen - resistance to chloride ion corrosion, lifespan increased by 3 - 5 times, avoiding metal contamination of salt./p>

Solve the problem of agglomeration:Dual anti - clogging system of ultrasonic waves + bouncing balls - screening efficiency of fine salt increased by 50%, reducing losses from downtime for screen cleaning./p>

Multi - grade output from one machine:Multi - layer screens for simultaneous classification (coarse/medium/fine) - outputting three specifications of salt in a single processing, saving equipment investment and floor space.

How to Select the Model ofsalt classifying with vibro sifteraccording to Salt Particle Size?

Accurately match the salt particle size to achieve efficient grading.

| Salt Particle Size Classification | Suitable Vibro Sifter Model | Typical Application Scenarios | Core Selection Criteria |

| Coarse salt (0.5–5mm) | Straight - through Vibro Sifter | Preliminary screening of sea salt and rock salt, removal of large impurities | - Single or double - layer screen, screen aperture ≥2mm (less than 10 mesh)- 304 stainless steel material, resistant to saltwater corrosion- High - capacity design, ≥5 tons/hour |

| Medium - fine salt (0.1–0.5mm) | Standard Three - Dimensional Vibro Sifter | Fine screening and classification of edible refined salt, water - softening salt, and feed salt | - Multi - layer screens (2 - 4 layers), screen aperture 20 - 60 mesh- 316L stainless steel contact parts, resistant to chloride ion corrosion- Fully enclosed moisture - proof structure, equipped with anti - clogging devices |

| Ultra - fine salt powder (<0.1mm) | Ultrasonic Vibro Sifter | Pharmaceutical salt, high - end seasoning salt, electrolytic salt powder | - Screen mesh number ≥200 mesh (74μm)- Standard ultrasonic system to prevent fine salt from blocking the screen- Food - grade silicone rubber seals, optional nitrogen protection interface |

How do these three types ofsalt classifying with vibro sifterwork?

Straight-through vibro sifter: Materials fall vertically into the center of the screen. Under low-angle vibration, qualified salt particles quickly pass through the screen and are discharged directly, while large impurities slide along the screen surface to the outlet. Coarse screening is completed in 5 seconds, making it suitable for high-flow primary screening.

Standard three-dimensional vibro sifter:A vertical motor drives the screen body to perform spiral three-dimensional movement. Salt particles jump forward in a parabolic trajectory on the screen surface. The vibration makes fine particles sink to contact the screen, and qualified particles accurately pass through the mesh. Multiple layers of screens simultaneously output coarse/medium/fine salt.

Ultrasonic vibro sifter:On the basis of standard vibration, an ultrasonic generator transmits 38KHz high-frequency waves to the screen. The acoustic micro-shock breaks up salt powder agglomerates, eliminates electrostatic adsorption, and increases the screening efficiency of ultra-fine salt powder by 80%.

、

| Model | Diameter (mm) | Feeding Size (mm) | Frequency (RPM) | Layers | Power (kw) | Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

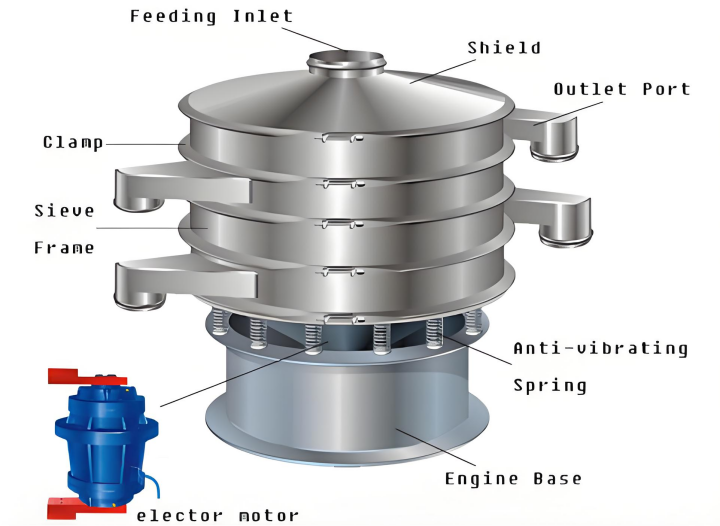

What is the structure of salt classifying with vibro sifter?

The structure ofSalt Classifying with Vibro Sifterconsists of these key components:

Base Frame:Sturdy structure supporting the entire unit.

Isolation Springs:Mounted between base and screen assembly, absorbing vibration.

Screen Deck:Holds stacked mesh screens (coarsest top, finest bottom) for multi-size classification.

Vibrating Motor:Mounted vertically on the screen frame, generating high-frequency vibration.

Central Weight System:Attached to motor shaft, controls vibration pattern.

Upper Cover:Seals the top, contains dust.

Inlet:Central feed point for salt.

Outlet Ports:Separate outlets for classified fractions (overs, mids, fines).

Where can thesalt classifying with vibro sifterbe applied?

Coarse salt (0.5–5mm):After impurity removal, it becomes an efficient road deicing agent and livestock licking block, with a melting point as low as -20°C and resistance to caking .

Medium-fine salt (0.1–0.5mm):It can be used as edible refined salt, which can be completely dissolved in 10 seconds; as regeneration salt for water softeners, it increases ion exchange efficiency by 40%.

Ultra-fine salt powder (<0.1mm):It can be used as pharmaceutical salt, high-end seasoning salt, and electrolytic salt powder.

What are the commom cases of saltclassifying withvibrosifter?

Common cases of salt classifying with vibro sifter include removing impurities from raw salt during edible salt production to achieve uniform particle sizes, such as sieving out agglomerates or foreign materials in refined salt processing. For example, a salt producer has adopted Salt Sieving Machinery's integrated sieving and crushing system to break down large salt crystals and classify them into multiple grades for food-grade, water treatment, and industrial applications. Vibro sifters can also separate salt particles into 2-6 predefined sizes in a single operation, ensuring precise grading according to different market requirements—such as fine table salt (20-40 mesh) or coarse industrial salt. These systems typically feature stainless steel construction and fully enclosed designs to maintain hygiene and reduce dust, much like DAHAN's salt shaker sifters, which are widely used in food-grade salt production.

The salt classifying with vibro sifter produced by our factory can achieve accurate and efficient salt particle screening. Its classification accuracy is stable at more than 98%, covering a wide screening range of 20 to 300 objects - from fine table salt of 20-40 objects to ultrafine salt powder of 200 mesh, it can achieve uniform grading. The equipment uses 316L stainless steel with Teflon-coated screen, which has excellent anti-chlorine ion corrosion ability and has a service life of 3-5 times longer than that of ordinary equipment, completely avoiding metal contamination of salt products. At the same time, it is equipped with a double anti-blocking system of ultrasonic + bouncing balls, which increases the efficiency of fine salt screening by 50%, and the processing volume can reach 100-2000kg/h (depending on the model), meeting the needs from small and medium batches to large-scale production. We can also provide customized services, including screening layers, screening mesh, equipment materials, etc.

Industry Sieve Machine

Industry Sieve Machine Powder Sieve Machine

Powder Sieve Machine Solid Liquid Separation Equipment

Solid Liquid Separation Equipment Ultrasonic Sieve

Ultrasonic Sieve