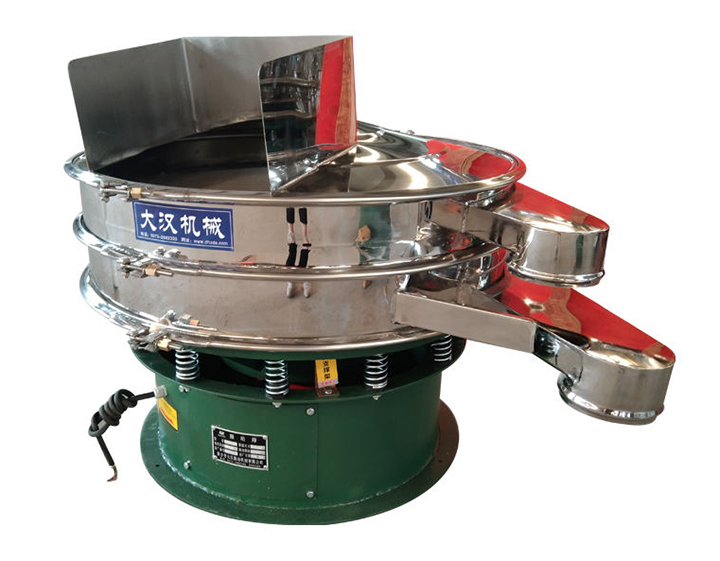

Ultrasonic Vibrating Screen Sieve Price

Friday July-18 2025 17:37:01

What is an ultrasonic vibrating screen sieve?

In industrial production,ultrasonic vibrating screen sieve is an important equipment for fine screening, and its price is the focus of enterprise purchase. With its unique ultrasonic technology, it can efficiently handle fine powder screening. The Ultrasonic Vibrating Screen Sieve Price varies depending on the configuration and specifications, which is around $300.00-$4,500.00 per set. It can not only meet the needs of small and medium-sized batch fine screening, but also adapt to a certain scale of production, and can provide accurate screening solutions for all walks of life.

What is the price of the ultrasonic vibrating screen sieve?

The price range of ultrasonic vibrating screen is $300.00-$4,500.00 per set, and it supports single set ordering, which is suitable for entry-level fine screening configuration and small batch production needs. In terms of power supply parameters, the equipment is equipped with a 900V high-frequency ultrasonic power supply with a rated power of 200W, and the ultrasonic system is independently powered. The power supply stability needs to be controlled within the fluctuation range of ±5%. The screen system uses S316L stainless steel, and the screen aperture is 50-600 mesh. It is also equipped with an ultrasonic recoil device to prevent clogging. This equipment is suitable for pharmaceutical intermediate screening, lithium battery positive electrode material grading, coating slurry filtration and other industries, focusing on solving the clogging problem of 50-600 mesh fine powder.

What is the specific price of the ultrasonic vibrating screen sieve?

| Model | 1-3 Layer Price Range (USD) | Capacity (T/H) |

| DHC400 | 600-800 | ≤3 |

| DHC600 | 645-818 | ≤5 |

| DHC800 | 1127-1463 | ≤8 |

| DHC1000 | 1494-1809 | ≤12 |

| DHC1200 | 1809-2124 | ≤16 |

| DHC1500 | 1762-2014 | ≤20 |

What are the advantages of the ultrasonic vibrating screen sieve?

Ultrasonic vibrating screen sievehas significant advantages, mainly reflected in high-precision screening, strong anti-clogging ability, high-quality and durable materials, stable power supply guarantee and other aspects.

High-precision screening: It has strong fine screening ability. With the help of 50-600 mesh screen, ultra-fine particle screening of 180μm-25μm can be achieved.

Strong anti-clogging performance: The ultrasonic recoil device effectively solves the clogging problem of 50-200 mesh fine powder, and ensures stable screening efficiency while meeting high-precision requirements.

High-quality and durable materials: 316L stainless steel wear-resistant screen is used to extend the service life of the equipment and reduce maintenance costs.

Stable power supply guarantee: 900V high-frequency power supply is independently powered to ensure the normal operation of the equipment within the power supply fluctuation range and ensure screening accuracy.

How to choose a suitable ultrasonic vibrating screen sieve?

Choosing an ultrasonic vibrating screen sieve requires comprehensive consideration of factors such as material properties, production requirements, industry requirements, and cost budget.

Material properties: Consider whether the equipment's anti-clogging ability and screening accuracy are appropriate based on the viscosity, humidity, and other characteristics of different fine powders.

Production requirements: Determine the order quantity based on the production scale. For small and medium-sized batch production, a single unit can be ordered, and the required mesh range must be specified.

Industry requirements: The pharmaceutical, lithium battery and other industries have high requirements for equipment materials and precision, and configurations that meet industry standards must be selected.

Cost budget: Within the price range, choose a cost-effective model based on equipment performance and long-term use costs.

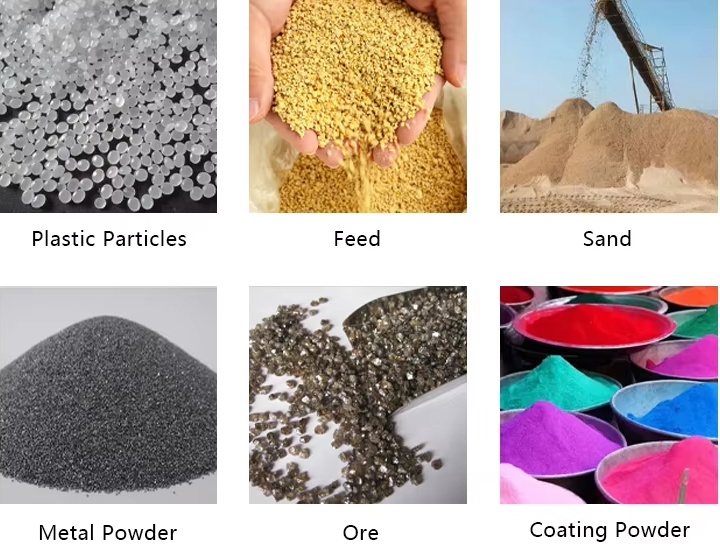

In which fields is the ultrasonic vibrating screen sieve applicable?

Ultrasonic vibrating screening machine is usually suitable for pharmaceutical, lithium battery production, coating and other industries.

Pharmaceutical industry: The ultrasonic vibrating screen sieve can perform high-precision screening of pharmaceutical intermediates, ensuring uniform particle size and meeting the strict requirements of GMP standards for drug purity.

Lithium battery production: It can classify cathode materials, improving the energy density and cycle life of batteries.

Coating industry: This equipment can effectively filter impurities and coarse particles in coating pastes, ensuring the color and texture of coatings.

The price of ultrasonic vibrating screen sieve directly reflects its technical content and application value. From ultrasonic technology that solves the problem of fine powder clogging to durable materials suitable for a variety of industries, each configuration will affect the price composition. When purchasing, enterprises need to comprehensively consider their own production needs, industry standards and cost budgets to choose the most suitable equipment. This equipment is not only a screening equipment, but also an important tool to improve product quality and enhance production competitiveness. Its reasonable price range also provides strong support for fine processing in various industries. In addition, we also provide customized services. If necessary, please contact.