Salt Classifying With Vibro Sifter Application

Friday July-18 2025 11:17:35

What is a salt vibro sifter?

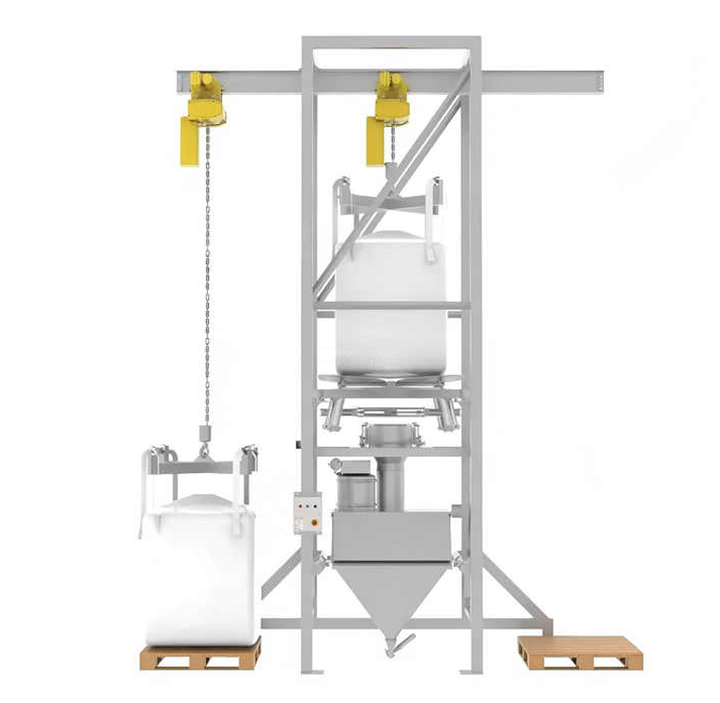

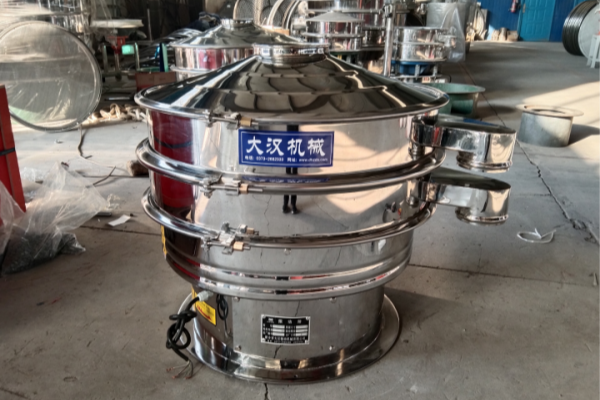

A salt vibro sifte is a vibrating screening device used to refine food-grade salt and industrial salt. It can generate powerful high-frequency vibrations through a motor, and can efficiently screen and grade salt. The stainless steel structure of the vibrating screen (304/316 material) ensures the corrosion resistance and hygienic operation of the equipment. The multi-layer precision screen can accurately separate salt particles of different particle sizes to ensure uniform distribution of salt particle size. The salt vibrating screen has high screening efficiency, large processing capacity, dust-proof closed design, easy cleaning and maintenance, which can significantly improve the quality of salt and optimize the entire salt production process.

What are the advantages of salt vibro sifter?

Compared with traditional equipment, the salt vibro sifter has higher grading accuracy; large processing capacity, and can be flexibly adjusted according to the model to meet different needs; 2-6 particle size grading can be completed in one operation without multiple processing. At the same time, the fully enclosed design of the salt vibrating grading screen reduces dust leakage, is easy to clean and maintain, and meets the hygiene standards of food-grade production.

Technical parameters of salt vibro sifter

| Name: | salt vibro sifter |

| Model | DH-800 |

| Layer | 1~5 |

| Power | 0.25Kw to 2.2Kw or customized |

| Mesh Size | 2~500 |

| Voltage | 220V |

| Materials | Carbon Steel,304,316Lstainless steel |

| Application | powder, granule, bulk solids, liquid |

| Customized service | Available |

What industrial scenarios can salt sifter be applied to?

Salt vibro sifter can be used in many fields, such as salt refining, chemical production, food and pharmaceutical industries. It can not only ensure good product quality, but also improve production efficiency for these fields.

Salt refining: In large-scale salt grinding operations, Salt vibro sifter play a key role in grading food-grade table salt, industrial salt crystals and sea salt flakes, removing lumps and fine impurities.

Chemical production: It can efficiently screen abrasive chemical compounds, moisture-sensitive particles and hygroscopic powder mixtures, and excels in situations where contamination control is critical.

Food and pharmaceutical: Ensure that edible salt, food additives and pharmaceutical-grade salt excipients are contaminant-free and meet strict HACCP and GMP compliance standards.

Minerals and ceramics: It can perform heavy-duty grading of abrasive materials (including silica sand, kaolin, ceramic glazes and industrial mineral powders) with low screen wear.

How can salt particles of different sizes achieve precise adaptation through salt vibro sifter?

For coarse salt (0.5-5mm), straight-through salt vibro siftes are adopted in salt vibro sifter, with single or double-layer screens matched with apertures ≥2mm, and the processing capacity reaches more than 5 tons/hour, suitable for initial impurity removal of sea salt and rock salt; medium-fine salt (0.1-0.5mm) is applicable to standard three-dimensional vibro sifters in salt classifying with vibro sifter, with 2-4 layers of screens to achieve 20-60 mesh classification, and the fully enclosed structure is moisture-proof and anti-pollution; ultra-fine salt powder (<0.1mm) relies on ultrasonic vibro sifters in salt classifying with vibro sifter, with 300 mesh screens combined with ultrasonic systems, which increases anti-clogging efficiency by 50% to ensure precise classification.

Case Study

A pharmaceutical manufacturer uses a salt vibrating screen to solve the problem of inconsistent purity of medicinal salt batches. Using a fully enclosed 316L stainless steel model with a 300 mesh ultrasonic screen, this customer produced ultrafine salt powder (particle size <75μm) with a purity of > 99.9%. This eliminated manual re-screening, reduced product rejection by 35%, and ensured continued compliance with GMP certification requirements for injection-grade salt production; A municipal winter maintenance department introduced a salt vibrating screen to optimize deicing efficiency. By using a heavy-duty straight-through model with a 3mm aperture screen, uniform grading of 1-4mm coarse salt was achieved (target particle size of 0.5-5mm). This reduced the amount of salt spread by 30% while maintaining effective ice melting at -20°C. This solution eliminated the problem of spreader clogging caused by oversized agglomerates, reduced fine salt waste, significantly reduced material costs per season, and extended equipment life.

The application of salt vibrating screens is essentially to maximize the value of salt particles through technical adaptation. From precise coverage of industrial scenarios, to efficient particle size classification, to targeted solutions to industry pain points, its applications are all supported by data - 20-300 mesh screening range, 98% classification accuracy, and 100-3300kg/h processing capacity, all of which confirm the reliability of the equipment. The customized services provided for different needs further make it indispensable in diversified applications, and continue to empower the quality and efficiency of the salt processing indust

Vibro Sifters For Sieving Molybdenum

Vibro Sifters For Sieving Molybdenum Industrial Sieve Machine

Industrial Sieve Machine Round Vibrating Sifter

Round Vibrating Sifter Test Sieve

Test Sieve