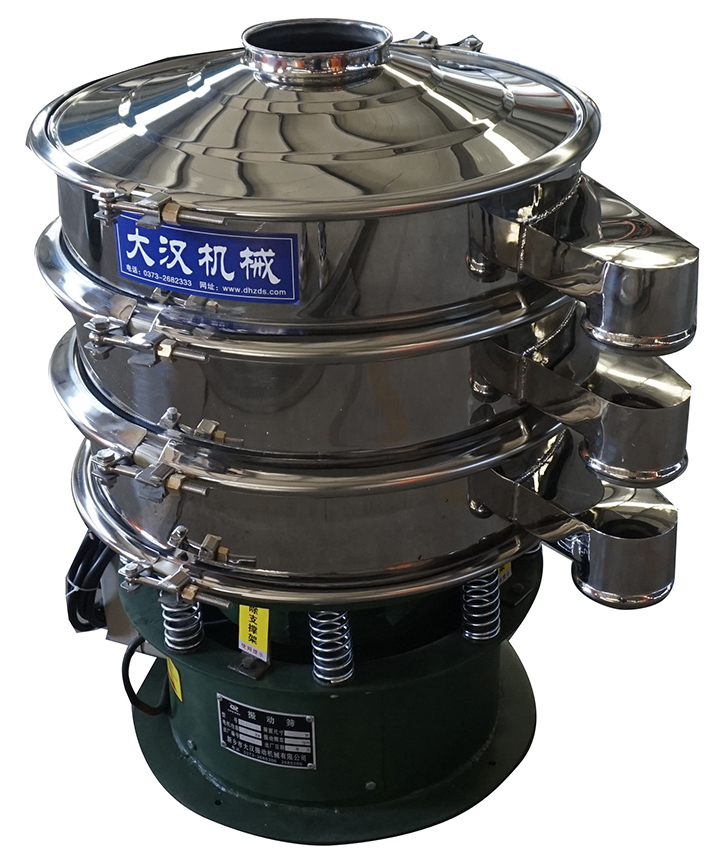

Glucose Powder Sieving Machine

The price of glucose powder sieving machine is between $650to $4800/Set,and it has the ability to prevent sticking, blocking and breaking up clumps.

layer:1-6 layers

Feed rate: 100kg/h - 20t/h

Mesh Size:2-800mesh

Applicable Particle Size:0.025-10mm

Power:0.18-5.5KW

What is a glucose powder sieving machine?

The Glucose Powder Sieving Machine is a sieving device designed for high-viscosity and easy-agglomeration powders such as glucose powder. It combines mechanical vibration with intelligent screen cleaning technology to achieve particle classification and impurity removal. The equipment is made of 304 stainless steel and can process 20-800 mesh glucose powder with a sieving accuracy of more than 98%.

Due to the high viscosity and easy agglomeration of glucose powder, high requirements are placed on the anti-sticking, anti-blocking and agglomeration capabilities of the sieving machine. For the full mesh number requirements of 20-600 mesh, the selection needs to match the characteristics and scenarios: 20-100 mesh coarse screening linear vibrating screen to quickly separate large impurities; 100-300 mesh medium screening with rotary vibrating screen to reduce the agglomeration of medium particles; 300-600 mesh ultra-fine screening ultrasonic screen to meet precision requirements, and 20-800 mesh easy-to-stick glucose powder, you need to choose an airflow screen to avoid powder adhesion.

What are the categories of glucose powder sieving machines?

Common types of glucose powder sieving machines include linear vibrating screens, rotary vibrating screens, ultrasonic vibrating screens and airflow screens. Each type has its own suitable material mesh and scenario.

Linear vibrating screen: suitable for coarse screening and impurity removal of 20-100 mesh glucose powder. It adopts double vibration motor to drive horizontal linear motion, and the screen surface shakes evenly, so that the glucose powder can be quickly layered. The processing capacity reaches 5-10 tons/hour, which is suitable for large-scale grading needs such as crystallization workshop and raw material initial screening;

Rotary vibrating screen: suitable for small and medium-scale screening of 20-300 mesh glucose powder. It adopts circular vibration trajectory and high-frequency shaking of the screen surface, which can make the glucose powder spread evenly, increase the screening rate by 30%, and process 1-3 tons per hour, which is suitable for medium-batch grading needs of food factories and beverage factories;

Ultrasonic vibrating screen: suitable for high-precision screening of 300-600 mesh ultrafine glucose powder. It superimposes 20-40kHz high-frequency vibration to destroy glucose powder agglomeration and solve the problem of fine powder blocking the screen. It is suitable for precision screening of pharmaceutical-grade and health-care-grade glucose powder;

Airflow screen: suitable for 20-800 mesh easy-to-stick glucose powder (such as agglomeration after moisture absorption). Through airflow-assisted vibration, the friction between powder and screen is reduced to avoid adhesion, which is suitable for production in the rainy season or high humidity environment in the south.

What are the core advantages of glucose powder sieving machine?

Glucose powder sieving machine has many advantages, such as adapting to multiple mesh requirements (covering >20 mesh coarse screen, 20-300 mesh medium screen, <600 mesh fine screen), matching different particle size classification scenarios through rotary vibrating screen, ultrasonic screen and other models; anti-sticking and anti-blocking design (304/316L stainless steel screen + Teflon coating + brush cleaning screen), reducing the blocking and shutdown of glucose powder due to moisture absorption and agglomeration; high-precision classification (ultrasonic screen accuracy of more than 95%), avoiding fine powder mixing to affect the purity of pharmaceutical/food grade raw materials; high-efficiency processing capacity (1-10 tons/hour), taking into account large-scale production and fine screening needs, and improving production efficiency; fully enclosed design, the equipment sealing reaches IP54 standard, the dust emission during the screening process is <10mg/m³, which meets GMP certification requirements and is suitable for the pharmaceutical and health care products industry.

Parameters of glucose powder sieving machine

Linear vibrating screen

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Vibro Sifter

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Ultrasonic vibrating screen

| Model |

Screen Diameter (mm) |

Sieving Area (m2) |

Screen Size (mesh) |

Layers |

Power (KW) |

| DHC-400 | 340 | 0.091 | 80-600 | 1~3 | 0.18 |

| DHC-600 | 540 | 0.229 | 0.25 | ||

| DHC-800 | 730 | 0.418 | 0.55 | ||

| DHC-1000 | 900 | 0.636 | 0.75 | ||

| DHC-1200 | 1100 | 0.95 | 1.1 | ||

| DHC-1500 | 1400 | 1.539 | 1.5 | ||

| DHC-1800 | 1700 | 2.269 | 2.2 | ||

| DHC-2000 | 1886 | 2.792 | 2.2 |

Airflow screen

| model | Material | power | Be applicable |

| WQS18-65 | Q235A | 2.2KW | Screening below 500 mesh |

| SUW304 | |||

| WQS30-100 | Q235A | 4KW | |

| SUW304 | |||

| WQS50-130 | Q235A | 5.5KW | |

| SUW304 |

What is the working principle of glucose powder sieving machine?

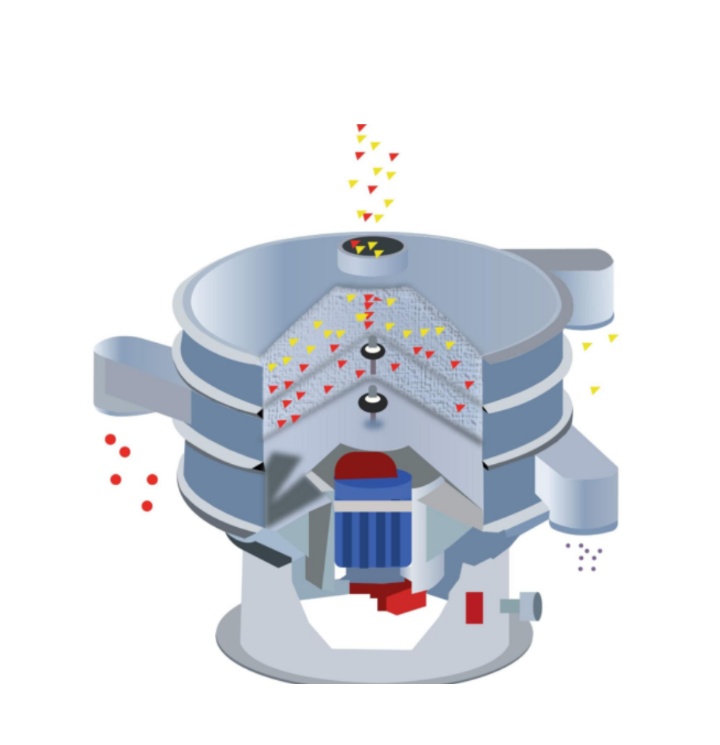

The equipment generates compound vibration through the driving device, and the horizontal axis swings left and right and combines with vertical micro-vibration to make the material form a spiral motion trajectory on the screen surface. Particles smaller than the screen hole penetrate the screen mesh under the action of gravity and vibration and fall into the aggregate trough; particles larger than the screen hole are discharged along the inclined direction of the screen surface. At the same time, the built-in rubber ball, rotating nozzle or ultrasonic system continuously cleans the screen hole to ensure stable screening efficiency.

What scenarios are suitable for glucose powder sieving machine?

In food production, the glucose powder sieving machine can accurately handle the grading of baking premixes, the removal of impurities in flavored syrups, and the uniformity control of milk powder particles; in the pharmaceutical field, it can complete the ultra-fine grading of medicinal glucose powder, the anti-caking treatment of probiotic solid beverages, and the fine screening of Chinese medicine extracts; in chemical production, it is suitable for the particle size screening of epoxy resin particles, the uniformity detection of polypropylene masterbatch, and the removal of agglomerates of carbon black powder; in health care product processing, it can efficiently complete the grading of oat dietary fiber powder and the screening of compound vitamin particles before uniform mixing.

The glucose powder sieving machine, with its precise adaptation to the full range of materials from 20 to 800 meshes, fundamentally solves the screening problem of high viscosity and easy-to-agglomerate powders through targeted designs of different models. The coarse screening linear screen quickly removes impurities, the medium screening uses a rotary vibrating screen to reduce agglomeration, the ultra-fine screen relies on ultrasonic screening to break the agglomerates and improve accuracy, and the easy-to-stick powder uses an airflow screen to prevent blockage. Whether it is large-scale coarse screening in food factories, ultra-fine screening in pharmaceutical workshops, or anti-sticking treatment in high-humidity environments, it can steadily improve efficiency and raw material quality.