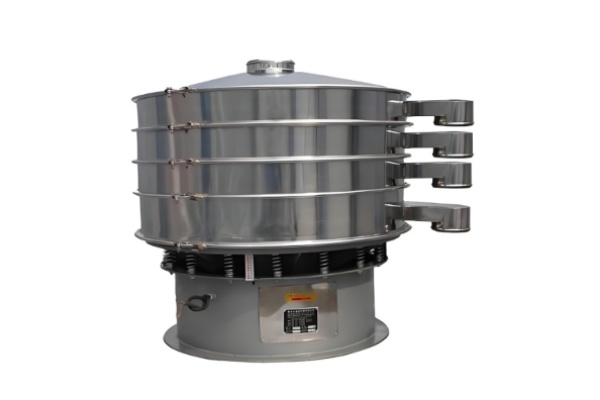

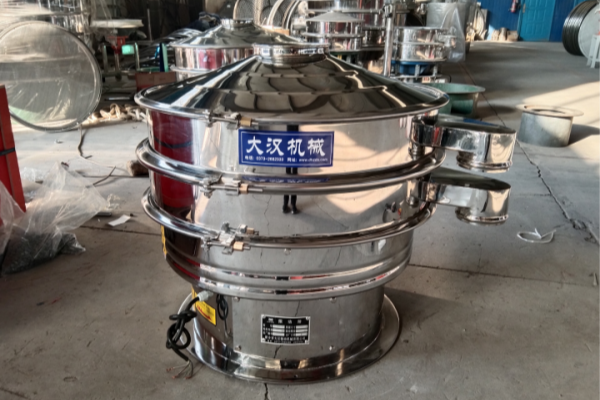

Foam Screening Machine

The price of Foam Screening Machine usually ranges from $800 to $5,000/Set.There are various models available, usually classified by screen surface diameter (e.g., 600mm, 800mm, 1800mm, etc.), applicable foam types (such as EPS recycled pellets, EVA foam, PU insulation foam, etc.), and screening mesh size (20-500 mesh).

Mesh size:20 mesh (0.85mm) to 500 mesh (0.028mm)

Output:0.5-5 tons/hour

Material:EPS, EPP, PE, PU, PP and other foam particles

layer:1-6 layers

What is Foam Screening Machine?

Foam Screening Machine is a vibration device used for grading and removing impurities of various foam materials such as EPS (polystyrene), EVA (ethylene-vinyl acetate), PP (polypropylene), PU (polyurethane), etc. The vibration motor drives the screen surface to produce three-dimensional movement, so that the foam is graded according to the particle size or impurities in the foam are removed. It can screen 10-500 mesh (corresponding to particle size 2-0.028mm) foam, while maintaining more than 99% particle integrity, and the output can reach 5 tons. The material is stainless steel 304/316L, which is corrosion-resistant and anti-static. The screen has 1-5 layers to choose from, which can accurately separate 2-6 different specifications of foam.

In the fields of foam recycling, food packaging, medical microsphere production, etc., traditional screening equipment often faces problems such as high foam breakage rate, electrostatic adsorption blocking, and low fine particle grading efficiency. Foam Screening Machine can effectively solve the screening problems of light foam particles, easy electrostatic adsorption, and irregular shape by optimizing vibration parameters and screen structure.

What types of Foam Screening Machine are there?

Foam Screening Machine can be divided into three types: standard type, stainless steel type, and ultrasonic type. You can choose according to the characteristics of the foam and the application industry.

Standard Foam Screening Machine: Suitable for dry screening of ordinary EPS and EVA foam particles, with a screening mesh of 20-200 mesh and a processing capacity of 1-5 tons/hour

Stainless steel Foam Screening Machine: Made of 304/316L stainless steel, it is clean and hygienic and suitable for screening food-grade foam and medical packaging foam

Ultrasonic Foam Screening Machine: With the addition of an ultrasonic device, it can screen PU foam and ultra-fine foam powder that are prone to electrostatic adsorption, with a mesh of up to 623 mesh

What are the advantages of Foam Screening Machine?

Foam Screening Machine can effectively solve the problems of clogging, crushing, electrostatic adsorption, low screening efficiency, etc. that occur when traditional equipment screens foam particles. The specific advantages are as follows.

High-efficiency screening: Adopting the principle of three-dimensional vibration, the material moves in an involute motion on the screen surface, with a screening efficiency of up to 90-95%, and a processing capacity 30% higher than that of ordinary vibrating screens

No clogging: Foam particles are prone to electrostatic adsorption, and the clogging rate of traditional screening machines is as high as 30%. Foam Screening Machine is equipped with a bouncing ball, a drum brush and an ultrasonic triple net cleaning device to ensure continuous production without clogging.

Material breakage: The low-speed swing design (only 1/3 of the speed of ordinary vibrating screens) combined with the involute motion trajectory protects the integrity of brittle foam particles, and the breakage rate is reduced to less than 0.5%.

Precise grading: It can accurately screen foam particles of 20-500 mesh (0.028mm-0.85mm), and divide the materials into 2-6 different particle sizes, with an accuracy of 95%-99%, meeting the strict requirements of different industries for foam particle size

Foam Screening Machine parameters

| Model | Screen surface diameter (mm) | Processing capacity (tons/hour) | Power (kW) | Screening layer number | Applicable foam type |

| DHC-600 | 600 | 0.5-1.5 | 0.25 | 1-3 | EPS recycling pellets |

| DHC-800 | 800 | 1.2-2.5 | 0.55 | 1-3 | EVA foam particles |

| DHC-1000 | 1000 | 2-4 | 0.75 | 1-4 | PP packaging foam |

| DHC-1200 | 1200 | 3-6 | 1.1 | 1-5 | PU insulation foam |

| DHC-1500 | 1500 | 5-8 | 2.2 | 1-5 | Mixed recycled foam |

| DHC-1800 | 1800 | 6-10 | 3.0 | 1-5 | Large foam crushing |

What are the applications of Foam Screening Machine?

Foam Screening Machine can be used to grade foam particles such as EPS, EPP, PE, PU, PP, etc. It can process dry and wet foam materials from 20 mesh (0.85mm) to 500 mesh (0.028mm). Applicable to:

EPS/EPP recycling industry: separation of plastic fragments, metal impurities, screening of 3-10mm recycled foam particles;

Packaging industry: classification of 1-5mm EPP buffer particles;

Medical/food industry: screening of 10-600μm PE microspheres, pharmaceutical carriers;

Industrial manufacturing: solid-liquid separation of PU foam slurry, wet screening and dehydration.

| Application scenario | Screening materials | Screening mesh number | Processing capacity (kg/h) | Recommended equipment | Solution highlights |

| A carbon factory in Norway: EPP foam recycling particle sorting | EPP particles (including plastic impurities) | 10-30 mesh | 500-800 | 1600mm swing type Foam Screening Machine | Bouncing ball net cleaning system, particle rate <0.3%, impurity separation efficiency 98% |

| A certain international pharmaceutical company: sterile grading of medical PE microspheres | PE microspheres (drug carrier) | 200-400 mesh | 300-500 | Stainless steel Foam Screening Machine | 316L material, CIP/SIP cleaning, in line with GMP standards, screening accuracy ±10μm |

| A food factory in Southeast Asia: fine screening of bread flour | Food grade EPS foam particles | 80 mesh | 200-400 | DH-800-1S standard | Anti-blocking net design, suitable for lightweight foam, screening efficiency increased by 40% |

| A European furniture filling manufacturer: PU foam slurry solid-liquid separation | Wet PU foam mixture | 20-60 mesh | 600-1000 | Anti-corrosion type (PP material) | Corrosion-resistant design, integrated dehydration function, moisture removal rate >90% |

What specific screening problems can Foam Screening Machine solve?

Foam Screening Machine offers targeted solutions to key issues in foam screening, covering common materials like EPS, EVA, PU, PP and scenarios from recycling to food/medical packaging.Static adsorption and clogging: For PU and other electrostatic-prone foams, traditional machines have a 30% clogging rate. Its triple cleaning system (bouncing ball + drum brush + ultrasonic) ensures 0 clogging.

Brittle foam breakage: For fragile EPS/EVA, traditional screens cause >20% breakage. Its low-speed swing (1/3 of ordinary screens) and involute trajectory reduce breakage to <0.5%.

Low efficiency of ultra-fine powder screening: For ultra-fine PU powder, traditional efficiency is <60%. The ultrasonic type screens up to 623 mesh with 90-95% efficiency.

Food/medical hygiene risks: For food/medical foam, traditional equipment may contaminate materials. The stainless steel type (304/316L) meets strict hygiene standards.

Multi-material/size adaptation: For EPS, EVA, etc. (2-0.02mm), 3 machine types + 1-5 screen layers accurately separate 2-6 specifications.

Our factory's Foam Screening Machine can efficiently process EPS, EVA, PU, PP and other foam materials. The screening range covers 10-623 items (corresponding to particle size 2-0.02mm), the screening efficiency reaches 90-95%, which is 30% higher than the ordinary vibrating screen processing volume. The maximum processing volume of a single unit can reach 10 tons/hour (such as DHC-1800 model). The equipment is made of 304/316L stainless steel, combined with triple net cleaning device (bounce ball, roller brush, ultrasonic wave), which completely solves the blockage problem. The low speed design makes the foam burst rate less than 0.5%, and the grading accuracy reaches 95%-99%. For different production needs, we can provide customized services based on the foam type, required mesh number and processing volume to ensure that the equipment accurately matches the actual production scenario.

Sieve For Polystyrene Pellets

Sieve For Polystyrene Pellets Vibro Sifters For Sieving Molybdenum

Vibro Sifters For Sieving Molybdenum Salt Classifying With Vibro Sifter

Salt Classifying With Vibro Sifter Powder Sieve Machine

Powder Sieve Machine