Coal Coarse Crusher

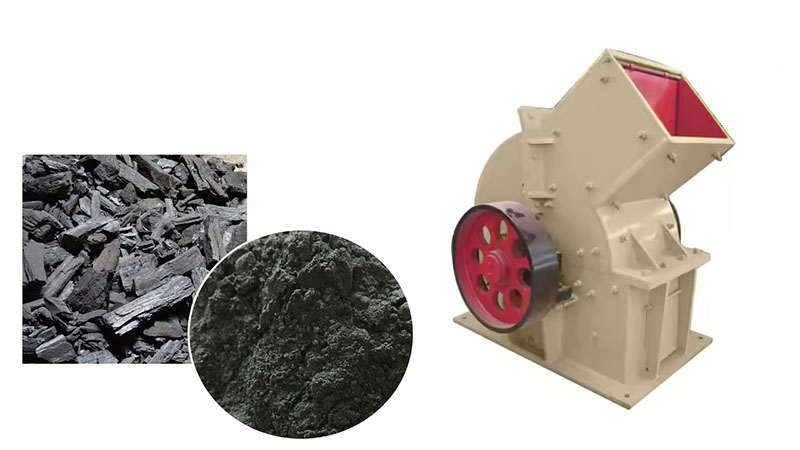

It is used to crush raw coal, lignite, anthracite, and other large coal lumps into smaller pieces or particles that meet subsequent processing standards through compression, impact, and other methods. Its price ranges from $900 to $12,000, with the specific price influenced by factors such as model, material, crushing capacity, motor power, and customization.

Feed size: Not exceeding 1800mm

Output particle size: 30-200mm

Processing capacity: 10-200t/h

Motor power: 160kW

What is Coal Coarse Crusher?

Coal Coarse Crusher is a crusher used in coal processing to crush raw coal or gangue with a particle size of 500-1800mm. It crushes large coal pieces into smaller pieces or coarse particles smaller than 200mm through compression, impact, and splitting, preparing them for subsequent processing or fine crushing. It can be used in coal mining, coal washing plant pretreatment, and coal chemical raw material preparation to crush different types and hardnesses of coal, such as raw coal, lignite, anthracite, and coking coal. Its crushing capacity ranges from 10 tons/hour for small-scale to 200 tons/hour for large-scale applications, meeting the production capacity needs of different users. In addition, due to the different hardness of coal and the dust generated during crushing, a dustproof sealing system and wear-resistant parts are adopted to reduce dust pollution and component wear while ensuring crushing efficiency.

Coal Coarse Crusher Video

What types of Coal Coarse Crusher are there?

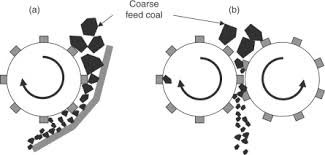

Depending on the hardness, particle size, and other properties of the coal being crushed, as well as the crushing amount, different types of Coal Coarse Crusher are selected, mainly including jaw, cone, and impact types.

| Type | Jaw Coal Coarse Crusher | Cone Coal Coarse Crusher | Impact Coal Coarse Crusher |

| Picture |

|

|

|

| Applicable coal | Anthracite (high hardness), lump coal (particle size>500mm), coal gangue | Bituminous coal (medium hardness), coking coal, gas coal | Lignite (high moisture content), long flame coal, weakly sticky coal |

| Crushing particle size range | Feed ≤1200mm, discharge 30-300mm adjustable | Feed ≤500mm, discharge 20-150mm adjustable | Feed ≤300mm, discharge 10-80mm adjustable |

| Core structure | PE series deep cavity jaw plate (Mn13Cr2 wear-resistant steel), wedge-type adjustment device | Compound crushing chamber, hydraulic overload protection system | Ball hammer impact crushing, adjustable gap between impact plates |

| Typical scenarios | The initial crushing of open-pit coal mines, such as the processing of 500-1000mm raw coal in a mine of Shenhua Coal Group | Pretreatment line of coal preparation plant, processing 300-500mm bituminous coal blocks | Crushing of coal chemical raw materials, such as pretreatment of lignite before coal slurry |

What are the advantages of Coal Coarse Crusher?

The Coal Coarse Crusher features a robust body structure and high-manganese steel wear-resistant components, enabling it to powerfully crush even hard coals containing gangue. It boasts strong resistance to impact loads and can handle large feed sizes up to 1800mm, crushing large pieces of coal to standard sizes in a single pass. The output size is adjustable from 30-200mm, with a crushing capacity of up to 200 tons/hour, adapting to various coal crushing needs. For wet coal with moisture content, its toothed design and anti-clogging structure prevent adhesion and blockage, ensuring continuous production. Custom sizes, crushing chamber structures, and power configurations are also supported.

Coal Coarse Crusher parameters

| Parameters | Grading roller crusher | Jaw crusher | Ring hammer crusher | Mobile crushing station |

| Feed size | ≤1800mm | ≤1500mm | ≤400mm | ≤1000mm |

| Discharge size | 50-300mm adjustable | 100-300mm | ≤25mm | 50-200mm adjustable |

| Processing capacity | 800-2500t/h | 500-2000t/h | 600-1200t/h | 200-800t/h |

| Motor power | 220-450KW | 160-400KW | 280-500KW | 200-350KW |

| Equipment weight | 45-85 tons | 30-75 tons | 25-50 tons | 60-100 tons |

| Applicable coal type | Various coals | High hardness coal | Medium hardness and below coal | Various coals |

| Power consumption per ton of coal crushed | ≤0.5kWh/t | ≤0.6kWh/t | ≤0.7kWh/t | ≤0.8kWh/t |

What are the applications of Coal Coarse Crusher?

Coal Coarse Crusher can be used in open-pit coal mines, underground coal mines, coal preparation plant pretreatment, thermal power plants, coal logistics centers, coking plants, coal gasification/liquefaction and other fields to crush different types of coal with a particle size within 1800mm, such as: crushed raw coal, lignite, bituminous coal, anthracite, and can also process mixed raw coal with gangue content ≤20%; crush medium and low hardness coal with Mohs hardness of 2-4 and wet coal with moisture content ≤15%.

Coal Coarse Crusher Customer Cases

Coal Coarse Crusher has been successfully applied in large, medium, and small coal mining projects in more than 200 countries, including South Africa, Indonesia, Australia, and China.

An open-pit coal mine in Australia: Using FP500 graded toothed roller coarse crusher with a processing capacity of 2500t/h, crushing 1800mm raw coal to less than 300mm, the equipment has been running continuously for 5 years without major repairs.

Zhungar Coal Mine in China: Two graded coarse crushers are used for high-quality coal and low-quality coal crushing production lines respectively. They have been in operation since 1993 and still maintain good performance.

South African coal mine project: A crushing system consisting of 47 small and medium-sized coarse crushers and 13 large machines can adapt to diverse mining conditions.

Indonesian lignite project: Using anti-blocking hammer coarse crusher, successfully processing lignite with a moisture content of 18%, with a production capacity of 1200t/h

MACHRISE Coal Coarse Crusher Manufacturer

MACHRISE Coal Coarse Crusher Manufacturer specializes in the research and development and production of equipment for crushing various types of coal. Our main products include jaw crushers for coarse crushing of hard coal, four-roll crushers, wet coal crushers, hammer crushers, ring hammer crushers, double-roll crushers, and cone crushers. We offer a complete range of models and specifications, with direct sales from the factory. Prices range from $900 to $12,000. In terms of materials, the hammers are mostly made of hot-dip chromium alloy or high-manganese steel, the main shaft uses 42CrMo, and the crushing chamber liners can be made of wear-resistant alloy steel or tungsten carbide coated steel. In addition to standard models, we also provide customized products or add-on functions based on coal properties, such as sealed dustproof structures, hydraulic overload protection, iron removal devices, explosion-proof designs, and mobile models.

Metal Coarse Crusher

Metal Coarse Crusher