Metal Coarse Crusher

This machine can crush large pieces of fibrous metal scrap and similar materials of varying hardness and texture into smaller sizes. It primarily achieves the desired particle size by reducing the volume of the metal scrap. The price ranges from $800 to $13,000.

Processing capacity: 1-1000 tons/hour

Feed size: Maximum 1500×1000mm

Discharge size: 2-100mm

Motor power: 55-500KW

What is Metal Coarse Crusher?

Metal Coarse Crusher is a coarse crusher used to crush large pieces of metal scrap. It can reduce the volume of large, irregular metal scrap by tearing, shearing or extruding it, turning it into smaller, more uniform particles with an output size between 2-100mm. This facilitates the processing and recycling of metal scrap, and the crushing capacity is 5-100 tons per hour.

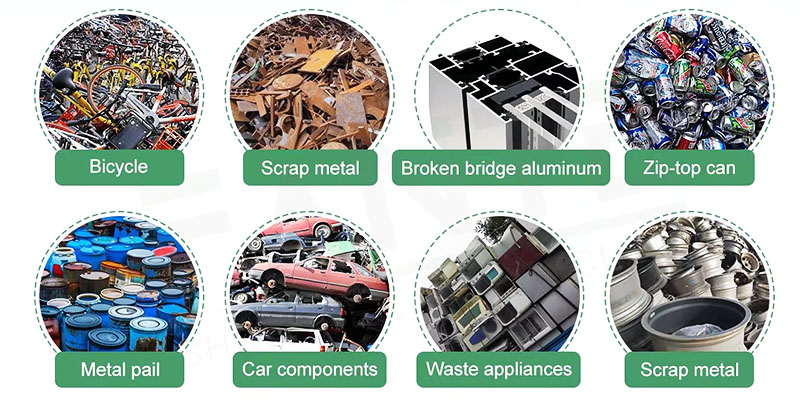

Metal Coarse Crusher can be used to crush tough, hard, and easily entangled metal materials such as scrap steel, scrap iron, aluminum alloys, iron ore, copper and aluminum, scrap stainless steel, and automobile shells. The material and structure of the equipment selected will vary depending on the properties of the material being crushed. For hard and brittle metals such as scrap steel, a jaw crusher can be selected for crushing by compression; for materials with a certain degree of toughness such as aluminum and copper, a hammer crusher should be selected for impact crushing to avoid adhesion and clogging; and for materials that require dust removal, a machine with a dust collection structure should be selected.

What types of Metal Coarse Crusher are there?

In addition to the standard model, the Metal Coarse Crusher also comes in three types: jaw, hammer, and hydraulic. Each type crushes different types of metal scrap, and there are also some differences in feed size, crushing capacity, and crushing method.

Standard Metal Coarse Crusher: This type uses shearing to crush metal scrap, capable of crushing metal scrap with a particle size ≤100mm, such as copper wire; it can also crush hard/tough materials with similar metal properties, with an output particle size of 0.5-20mm. Different models have different crushing capacities, such as CSJ-120 (80-300kg/h), CSJ-400 (300-1200kg/h), and CSJ-800 (500-1500kg/h).

Jaw Metal Coarse Crusher: This machine crushes high-hardness, large-volume scrap steel, iron ore, copper and aluminum blocks, and automotive shredder residue through compression. It has a high crushing ratio, with a discharge particle size of 20-150mm and a processing capacity of 50-160t/h.

Hammer Metal Coarse Crusher: High-speed rotating hammers impact and crush medium-hardness metals, such as automotive shells, canned goods, and household appliance waste. It can be used in conjunction with magnetic separators to separate metals and non-metals. Output particle size is 0.3mm - 50mm, with a processing capacity of 5t/h - 200t/h.

Hydraulic Metal Coarse Crusher: Driven by hydraulic pressure, it continuously crushes metal in layers. It has built-in overload protection and can crush metal blocks ≤1200mm. It is commonly used for crushing ultra-large metal waste such as steel plates from construction machinery and shipbuilding; output particle size is 6mm - 51mm.

Why choose Metal Coarse Crusher?

Made of stainless steel, the Metal Coarse Crusher is sturdy and durable, capable of crushing metal waste of various shapes and hardnesses. The appropriate crushing chamber structure, such as jaw, hammer, or roller crushers, can be selected based on the properties of the metal material being crushed. It can handle various metal shapes, from thin metal sheets to heavy steel beams, producing uniform particle sizes. Screen sizes are available from 2-100mm, and the output size can be adjusted by changing the mesh size. For metal waste containing foreign objects, a magnetic separation feeding device can be added to prevent material contamination. Customization of feed inlet, material, output size, and configuration parameters is also available to suit the needs of everything from small processing plants to large-scale metal recycling production lines.

What is the working principle of Metal Coarse Crusher?

Metal Coarse Crusher mainly crushes metal materials by extrusion, splitting, impact and other methods; when large pieces of metal enter the crushing chamber evenly through the vibrating feeder, the movable jaw plate and the fixed jaw plate squeeze each other, or the hammer head impacts at high speed, causing the metal to break and deform. The crushed metal particles are discharged through the screen, and the materials that do not meet the standards continue to be crushed in a cycle.

Metal Coarse Crusher Parameters

| Model | Maximum feed size (mm) | Discharge port adjustment range (mm) | Processing capacity (t/h) | Motor power (kW) |

| PE400×600 | 340 | 40-100 | 16-64 | 30 |

| PE600×900 | 500 | 65-160 | 50-160 | 55 |

| PE900×1200 | 750 | 100-200 | 220-380 | 110 |

| PE1200×1500 | 1020 | 150-350 | 400-1000 | 160-245 |

What are the applications of Metal Coarse Crusher?

Metal Coarse Crusher can be used in metallurgical smelting pretreatment, manufacturing waste recycling, scrap steel recycling plants, automobile dismantling plants, metal processing plants, and home appliance recycling plants to crush large, irregular metal waste into smaller, uniformly sized blocks or granules. The metal waste that can be crushed includes block and profile metals such as scrap steel, scrap iron, aluminum alloys, copper alloys, and scrap stainless steel, as well as shaped or loose metal waste such as car shells, waste home appliance shells, metal drums, rebar ends, waste pipe fittings, aluminum profile scraps, and copper wire bundles. It is also suitable for some mixed metal waste with slight impurities.

Metal Coarse Crusher Client Case

| Industry Sector | Material Types Processed | Processing Capacity | Feed Size | Output Size |

| Scrap Steel Recycling | Mixed Metal Scrap: 70% Thin Steel Plate + 30% Castings | 120 tons/day | ≤300mm | 50-150mm |

| Industrial Waste Treatment | Loose scrap steel including color steel tiles and car bodies | 15 tons/day | ≤1.5 meters | 80-200mm |

| Comprehensive Solid Waste Treatment | Mixed steel and aluminum scrap from scrapped car bodies + industrial offcuts | 120 tons/day | ≤200mm | 30-100mm |

| Mining | Iron ore | 180-300 tons / Hour | ≤300mm | 30-80mm |

| Scrap Steel Recycling | Small and Medium-Sized Scrap Steel Profiles | 90 tons/day | ≤200mm | 50-150mm |

| Nickel Ore Mining | Nickel Ore | 200 tons/hour | ≤250mm | 40-100mm |

Metal Coarse Crusher Manufacturer

MACHRISE Metal Coarse Crusher manufactures a variety of products for crushing metal scrap, including standard, jaw, hammer, hydraulic, roller, and twin-shaft shredders. These shredders can handle hard, flexible, and brittle metal scrap, with a crushing size up to 1500mm. The output screen can be configured according to requirements, and materials include stainless steel and high-manganese steel. The crushing capacity is suitable for everything from small family workshops to large factories. Customization is also available, such as mobile models with explosion-proof devices, iron removal devices, and dust removal devices. Factory direct sales, 1-year warranty.

Hammer mill

Hammer mill