Heavy Duty Coal Coarse Crusher

Tuesday December-02 2025 17:42:52

Heavy Duty Coal Coarse Crusher reduces the volume of large coal pieces, crushing coal larger than 1000mm into smaller lumps or coarse particles, with an output particle size of 50-300mm. It can provide raw materials for subsequent processes such as medium and fine crushing, sorting, and grinding in coal processing. The coal itself has high hardness, and some have high gangue content. The parts in contact with the coal are made of high manganese steel with strong impact resistance, and the 5mm thickened lining plate has strong wear resistance. The maximum crushing capacity can reach 500 tons per hour.

Heavy Duty Coal Coarse Crusher video

What types of Heavy Duty Coal Coarse Crushers are available?

Heavy Duty Coal Coarse Crushers can be used to crush coals ranging from low to high hardness, but the type of machine used varies. The main types are single-roll, jaw, and hammer crushers.

Single-roller Heavy Duty Coal Coarse Crusher: Utilizes a high-speed rotating roller with fixed liners to compress and crush coal. The fixed distance between the crushing surfaces ensures uniform particle size and prevents over-crushing, resulting in good particle shape integrity. Suitable for medium-hardness raw coal with a particle size ≤800mm and a moisture content ≤12%. The output particle size is adjustable from 20-100mm, with a crushing capacity of 50-300 tons/hour.

Jaw Heavy Duty Coal Coarse Crusher: Crushes coal through the squeezing and shearing action between a moving jaw and a fixed jaw. Suitable for crushing large pieces of coal with a particle size ≤1200mm, abrasive coal containing gangue, and high-hardness raw coal. The output particle size is controlled between 30-150mm, and its crushing capacity is large, reaching up to 500 tons/hour.

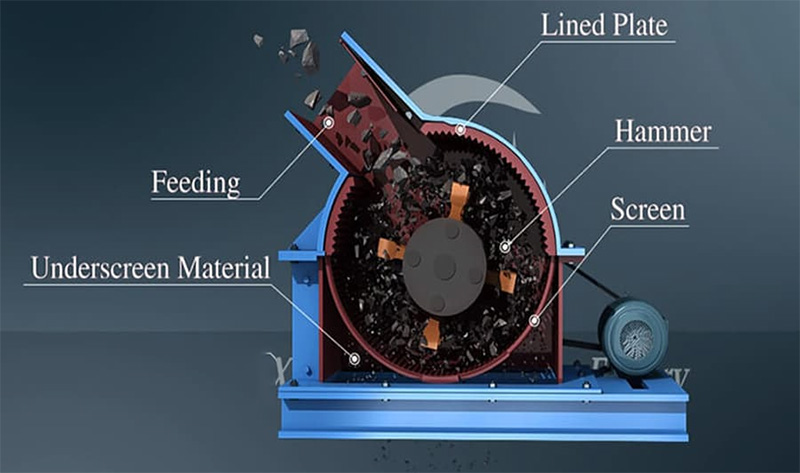

Hammer Heavy Duty Coal Coarse Crusher: A rotor rotating at 1000-1500 rpm drives hammers to rotate at high speed, striking the coal and causing it to impact and be further crushed by a counter-impact plate. Through continuous crushing, the coal is screened into qualified particles. It has a large crushing ratio, with an output particle size of 10-50mm. It can be used to crush low-hardness coal up to 600mm in diameter, with a crushing capacity of 30-200 tons/hour.

What are the advantages of a Heavy Duty Coal Coarse Crusher?

The Heavy Duty Coal Coarse Crusher boasts high crushing efficiency and output, employing a large-diameter rotor, deep crushing chamber, and high-power motor drive. It features a large single feed capacity and fast crushing speed, processing 50-500 tons per hour. Components in contact with coal, such as jaw plates, hammers, toothed rollers, and bearings, are made of high-manganese steel or wear-resistant alloys, offering strong impact resistance and wear resistance, ensuring stable operation even under harsh, high-load conditions. It can handle low-hardness, medium-hardness, and high-hardness coals with moisture content. Customized feed inlet size, motor configuration, and overall dimensions are also available.

How does the Heavy Duty Coal Coarse Crusher work?

When the Heavy Duty Coal Coarse Crusher is in operation, the coal is fed into the feed inlet by the feeding device. After the coal enters the crushing chamber through the feed inlet, it is impacted by the high-speed rotating hammers. The coal that has been impacted and crushed is repeatedly collided and squeezed between the hammers and the casing liner and screen plate, and is slowly crushed into coarse particles. The coarse particles that meet the discharge size are discharged from the discharge port through the screen holes. The coal that is intercepted remains in the crushing chamber and continues to be crushed until it meets the discharge requirements.

Heavy Duty Coal Coarse Crusher Parameters

| Parameter Category | Single Roll Crusher | Jaw Crusher | Hammer Crusher |

| Processing Capacity (t/h) | 200-1500 | 100-1200 | 300-3000 |

| Feed particle size (mm) | ≤1200 | ≤1500 | ≤1000 |

| Discharge particle size (mm) | 50-300 | 50-250 | 25-100 |

| Motor power (kW) | 75-400 | 55-400 | 200-1250 |

| Equipment weight(t) | 20-80 | 15-100 | 30-150 |

| Applicable Coal Hardness | Medium Hard, Cohesive | Medium Hard to Hard | Medium Hard, Brittle |

What are the applications of Heavy Duty Coal Coarse Crusher?

Heavy Duty Coal Coarse Crusher is used in mining, thermal power generation, and building materials processing industries for crushing raw coal at coal mine entrances, pre-treatment of coal for power plant boilers, material crushing at coal transfer stations, and recycling of coal gangue. It can crush anthracite, bituminous coal, lignite, coking coal, lean coal, and fat coal with a particle size ≤1000mm. It can also process coal raw materials with a compressive strength ≤150MPa and moisture content ≤12%, ranging from hard anthracite to bituminous coal containing moisture.

Heavy Duty Coal Coarse Crusher Customer Case

In a large open-pit coal mine's post-mining pre-processing scenario, there was a need to process medium-hard raw coal with a size of approximately 800mm and containing a small amount of gangue. This coal needed to be crushed into uniform 25mm particles. The chosen heavy-duty coal coarse crusher utilizes high-speed rotating hammers to impact and crush the material. Adjustable grate spacing controls the discharge precision, effectively meeting the customer's feeding requirements for subsequent processing. The crushing capacity is 250-320 tons per hour.

Coal Coarse Crusher

Coal Coarse Crusher