Stone Coarse Crusher

It uses mechanical forces such as compression and impact to crush large stones of different hardness and particle size into small pieces with a particle size of less than 300mm, reducing the volume of large stones to meet the size requirements of subsequent processing. Its price ranges from $680 to $17,000.

Feed size: ≤1200mm

Discharge size: 10-400mm (adjustable)

Processing capacity: 1-3000t/h

Motor power: 5.5-630kW

What is Stone Coarse Crusher?

A stone coarse crusher is a machine that breaks down large stones into smaller, coarse particles to meet specific requirements. It crushes large stones such as granite, limestone, and basalt into smaller particles through compression or impact, providing raw materials for subsequent medium and fine crushing or concrete production. It is generally used for primary stone crushing, with a feed size of 500-1500mm and an output size that can be adjusted according to needs, typically from 100mm to 300mm. The crushing capacity ranges from 500 to 800 tons per hour, and it can be used in everything from small quarries to large mining production lines.

The stone coarse crusher can crush stones of varying hardness. Durability is a key consideration in material selection; high-manganese steel or wear-resistant alloys are used for core wear parts such as jaw plates and hammers. The machine body is welded from high-strength carbon steel, offering impact resistance and wear resistance, ensuring stable operation under heavy loads.

What are the types of Stone Coarse Crusher?

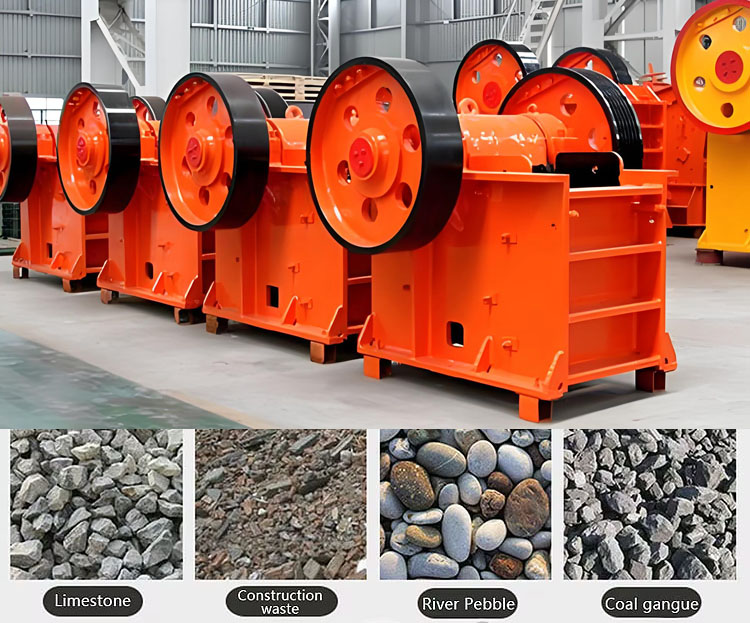

Common types of stone coarse crushers include jaw crushers and impact crushers. They differ in their working principles, types of stone they can crush, feed and discharge particle sizes, and crushing capacity. The appropriate equipment can be selected based on the properties of the material to be crushed.

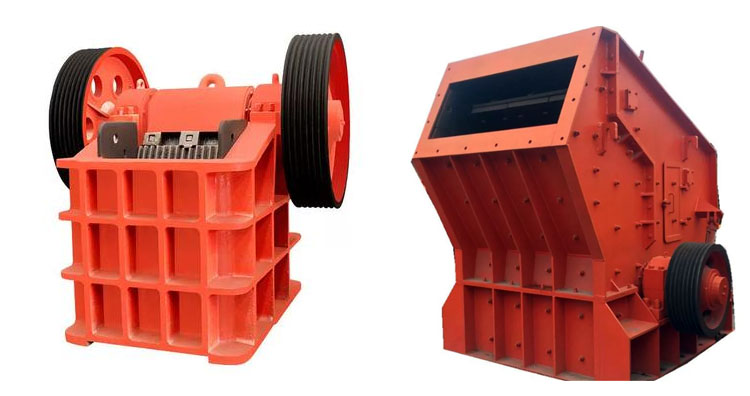

Jaw Stone Coarse Crusher: This type crushes stone through compression between a stationary jaw and a moving jaw. When the moving jaw approaches the stationary jaw, the stone is crushed; when it moves away, the crushed stone is discharged from the outlet. It has a simple structure, stable operation, and can be used for crushing high-hardness or medium-hardness materials such as granite, basalt, and iron ore. Feed size range is 500-1500mm, discharge size is 100-300mm, and crushing capacity is 100-800t/h.

Impact Stone Coarse Crusher: It relies on a high-speed rotating rotor to drive hammers to strike and impact the stone. The stone is repeatedly crushed under the impact force, with a large crushing ratio and uniform output particle shape. It can crush medium-hardness and brittle stones such as limestone, marble, and shale, but it is not suitable for crushing high-hardness materials. Its feed size is 300-800mm, output size is 50-200mm, and crushing capacity is 50-500t/h.

What are the advantages of Stone Coarse Crusher?

The Stone Coarse Crusher features a widened feed inlet design, capable of crushing large stones up to 1500mm in diameter. The crushing chamber structure is selected based on the type of stone being crushed, and combined with wear-resistant jaw plates or hammers, it easily handles the intense wear and impact from stones of varying hardness. It is robust and durable, reducing material blockage and ensuring stable operation. With a large crushing capacity of up to 800 tons and high crushing efficiency, it can quickly crush large stones to a uniform coarse particle size, preparing them for subsequent processing. The output particle size can be adjusted according to the standards of the crushed stone.

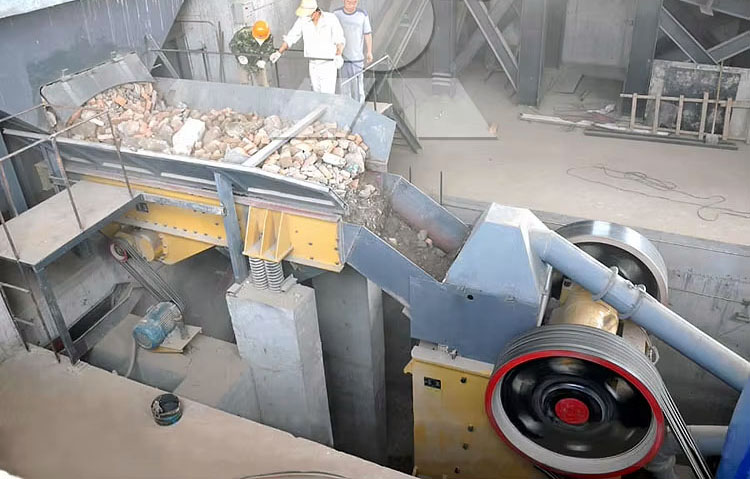

How does Stone Coarse Crusher work?

After being fed into the crushing chamber through the inlet, the Stone Coarse Crusher is crushed by mechanical forces such as squeezing, impact, and splitting generated by the motor. The crushed stones that meet the specifications are discharged from the outlet through the screen, while the stones that do not meet the specifications continue to be crushed in the crushing chamber until they meet the standards and are discharged.

Stone Coarse Crusher parameters

| Model | Opening size(mm) | Max feeding size(mm) | Output adjust range(mm) | Production capacity(t/h) | Power(kw) |

| PE250*400 | 250*400 | 200 | 20-50 | 5-20 | 15 |

| PE400*600 | 400*600 | 350 | 40-100 | 15-60 | 30-37 |

| PE500*700 | 500*700 | 425 | 50-100 | 40-110 | 45-55 |

| PE600*900 | 600*900 | 480 | 65-160 | 90-180 | 55-75 |

| PE750*1060 | 750*1060 | 630 | 80-140 | 110-320 | 90-110 |

| PE900*1200 | 900*1200 | 750 | 95-165 | 220-450 | 110-132 |

| PE1200*1500 | 1200*1500 | 1020 | 150-300 | 400-800 | 160-220 |

What are the applications of Stone Coarse Crusher?

Stone Coarse Crusher is used in the construction, mining, road, and aggregate production industries for crushing stone. It can break stones of different shapes and sizes into smaller particles. It can crush various types of stone, including iron ore, copper ore, granite, basalt, limestone, marble, dolomite, shale, coal gangue, gypsum, quartz sand, sandstone aggregate, and artificial marble, providing qualified raw materials for subsequent medium crushing, fine crushing, or batching processing.

Stone Coarse Crusher Customer Cases

| Application Cases | Crushed Materials | Feed Size | Discharge Size | Crushing Capacity |

| A Southeast Asian Construction Aggregate Production Project | Limestone | Maximum 750mm | ≤200mm | 500t/hour |

| Indonesia River Basalt Crushing Project | River basalt | Maximum 500mm | 0-63mm | Approximately 100t/hour |

| China High-Standard Sand and Gravel Production Line | Mixed Hard Rock of Mountain Rock, River Pebbles, and Granite | Maximum 1200mm | ≤150mm (Suitable for medium crushing needs) | 800t/hour |

| India Construction Aggregate Project | Dolomite (containing some limestone) | Maximum 800mm | ≤200mm | Approximately 400 tons per hour (with a supporting production line of 9.5 million tons per year) |

MACHRISE Stone Coarse Crusher Manufacturer

MACHRISE Stone Coarse Crusher manufactures a variety of stone processing equipment, including jaw crushers, impact crushers, cone crushers, roller crushers, and mobile crushers. We offer direct sales from the factory, with prices starting as low as $600 USD. All equipment is made of wear-resistant high-manganese steel, ensuring a long service life. Customized solutions and additional features are available based on different stone properties, such as hardness, moisture content, and abrasiveness. These include features like large feed openings, explosion-proof designs, high-temperature resistant models, hydraulic drive systems, and integrated crushing and dust removal systems.

Hammer mill

Hammer mill

Aggregate Coarse Crusher

Aggregate Coarse Crusher Minerals Coarse Crusher

Minerals Coarse Crusher