What is the difference between a coarse crusher and a fine crusher?

Thursday October-30 2025 17:47:41

In the sand and gravel aggregate production industry, choosing the wrong crushing equipment can lead to endless headaches: frequent component replacements, high energy consumption, substandard products, and squeezed profit margins. Faced with a wide variety of crushing equipment, many customers are often confused: should they use a coarse crusher or a fine crusher for their material?

The crushing process is typically divided into three stages: coarse crushing, secondary crushing, and fine crushing (or shaping). So, what is the difference between a coarse crusher and a fine crusher in the crushing process?

Coarse crushers: Used for initial crushing, they reduce large, mined raw materials (≤1500mm) to smaller pieces of 100-300mm. They handle the first stage of crushing large, bulky raw materials.

Fine crushers: Used for the precision shaping stage, they further crush the medium-crushed material (usually ≤100mm) to 0-10mm or even finer (0-5mm), achieving a final product with excellent particle shape and meeting required specifications. This is a critical step in the process of reaching the final product.

| Comparison dimensions | coarse crusher | fine crusher |

| Feeding particle size | ≤1500mm | ≤100mm |

| Discharge particle size | 100-300mm | 0-10mm (usually 0-5mm) |

| Typical equipment | Jaw crusher, gyratory crusher | Vertical shaft impact crusher, short-head cone crusher, high-efficiency impact crusher |

| Main tasks | Initial volume reduction, reducing material volume | Precise shaping, controlling finished product particle size and shape |

| Particle quality | General, high in needle-like content | Excellent, high in cubic content, low in needle-like content |

| Structural Features | Simple and sturdy structure, strong impact resistance | Complex and precise structure, emphasizing "shaping" function |

| Applicable Scenarios | Mine crushing and initial processing of large rough stones | High-quality building materials, machine-made sand, and fine aggregate production |

What are the coarse crushers?

The main coarse crusher equipment includes jaw crushers and gyratory crushers.

The jaw coarse crusher is an all-rounder in the primary crushing field, accounting for over 80% of primary crushing applications. It features a simple and reliable structure, a large feed opening (up to 1m x 1.3m), and can directly handle boulders up to 1500mm in size. Its price is only 60-70% of similar equipment.

Disadvantages: The output particle shape is poor (needle-like content >15%), the liner wears quickly, and subsequent secondary and tertiary crushing equipment is required.

Gyratory coarse crusher: Optimized for high production volumes, it offers high continuous crushing capacity, with an output of over 2000 tons per hour. It does not require a feeder and can be fed directly with large materials.

Disadvantages: The jaw crusher is 5-8 meters tall, the infrastructure cost doubles, and the price is 2-3 times that of a jaw crusher.

At what stage of material processing should a primary crusher be selected?

Choose a coarse crusher if your material meets any of the following characteristics:

Raw material size > 500mm (e.g., raw ore after blasting, large blocks of building concrete)

Target particle size between 100-350mm

Subsequent secondary and fine crushing steps are required

Capacity requirement > 500 tons/hour (gyratory crusher preferred) or < 500 tons/hour (jaw crusher preferred)

What types of fine crushers are there?

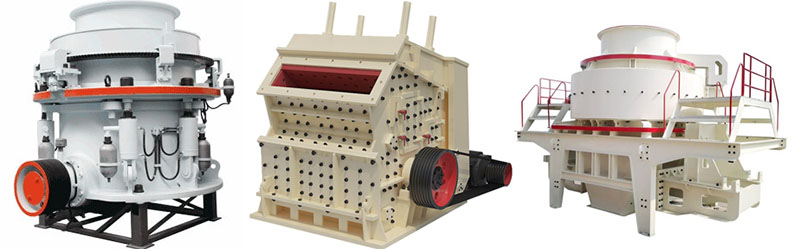

Common types of fine crushers include cone, impact, and vertical shaft impact crushers. Details are as follows:

Cone crusher (short head): This is a wear-resistant tool for finely crushing hard rock. It offers exceptional wear resistance and is suitable for hard materials such as granite and basalt. The finished product has a uniform particle shape (less than 10% needle-like flakes) and can reach 700 tons per hour.

Disadvantages: Complex structure, single-cylinder hydraulic cone crushers cost over one million yuan; prone to plugging with sticky materials with moisture content > 5%. Impact Crusher: Designed for fine crushing of medium-hard materials, with a cubic content of >85% in the finished product. For example, the 1414 model can produce fine sand 0-10mm in diameter, with an output of 50-150 tons per hour. The equipment investment is only 60% of that of a cone crusher.

Disadvantages: Rapid hammer wear; when crushing basalt, the lifespan is only one-third of that of a cone crusher; feed material requirement ≤150mm.

Vertical Shaft Impact Crusher (VSI Sand Making Machine): Utilizing a "rock-on-rock" or "rock-on-iron" principle, the finished product is highly rounded and has a high bulk density, making it an excellent choice for high-quality concrete aggregate.

Disadvantages: Feed size ≤50mm; high maintenance costs in the event of equipment failure.

When should you choose a Fine Crusher?

When your process requires:

Discharge size <30mm (especially 0-5mm machine-made sand);

Quality in finished product shape (cubic content >80%);

The raw material is already coarsely crushed to a medium particle size of 100-150mm;

Processing material with a moisture content <8% (to avoid cavitation).

Reference table for crushing of common materials

| Material Type | Feed Particle Size (mm) | Discharge Particle Size (mm) | Crushing Method | Recommended Equipment Type | Production Output (t/h) | Applicable Stages | Remarks |

| Granite | ≤1200 | 10-350 | Extrusion Crushing | Coarse Jaw Crusher (PE Series) | 50-1000 | Coarse Crushing | High hardness, faster liner wear |

| Granite | ≤300 | 5-60 | Laminated Crushing | Cone Crusher (PYB Type) | 50-800 | Medium and fine crushing | Good wear resistance, suitable for hard rock |

| Iron ore | ≤1500 | 10-400 | Extrusion crushing | Coarse jaw crusher (CJ European version) | 1-2200 | Coarse crushing | High crushing ratio, low energy consumption |

| Iron ore | ≤300 | ≤60 | Laminated crushing | Cone crusher (multi-cylinder hydraulic) | 110-2181 | Medium and fine crushing | Automatic iron overload protection, suitable for high-production lines |

| Limestone | ≤1200 | 10-350 | Extrusion crushing | Coarse jaw crusher (PE series) | 50-1000 | Coarse crushing | Simple structure, easy maintenance |

| Limestone | ≤110 | 5-25 | Impact crushing | Impact Crusher | 50-500 | Fine Crushing | Good particle size, suitable for medium-hard materials |

| Basalt | ≤1200 | 10-350 | Extrusion Crushing | Coarse Jaw Crusher (German Version) | 50-1000 | Coarse Crushing | Highly wear-resistant liner, high compressive strength |

| Basalt | ≤300 | 5-60 | Laminated crushing | Cone crusher (single-cylinder hydraulic) | 100-700 | Medium and fine crushing | Low energy consumption, suitable for hard rock fine crushing |

| Construction waste | ≤400 | 75-250 | Extrusion crushing | Jaw crusher | 45-1500 | Coarse crushing | High adaptability, can handle mixed materials |

| Construction waste | ≤75 | 3-15 | Impact crushing | Cone crusher (short head type PYD) | 18-100 | Fine crushing | Uniform particle size, suitable for recycled aggregate |