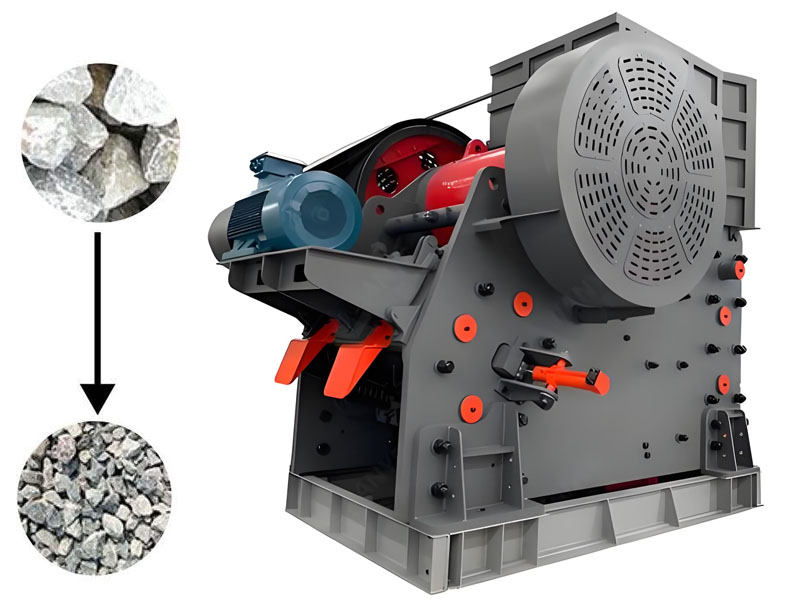

Aggregate Coarse Crusher

A crusher used to process large coarse aggregates such as sand, gravel, crushed stone, etc. into the required size.

Price: $800-$490,000

Feed size: 500-1500mm

Discharge size: 50-300mm

Production: 50-2000 tons/hour

What is Aggregate Coarse Crusher?

Aggregate Coarse Crusher can crush large stones of 500-1500mm into smaller particles. It reduces the volume of the raw ore or rock by jaw compression, providing raw materials for subsequent medium and fine crushing or aggregate processing in construction, road and other projects. The output particle size is adjustable from 50-300mm, and the crushing capacity is 50-2000 tons per hour.

The finished product size of Aggregate Coarse Crusher is 0-5mm, 5-10mm, 10-20mm, 20-40mm, 40-60mm, or even larger. The size of the required aggregate can be controlled by adjusting the discharge port. The material is mostly high manganese steel or alloy steel with strong wear resistance. It is widely used in building stone, cement raw material processing, ore processing in ore processing plants, etc.

What types of Aggregate Coarse Crusher are there?

Aggregate coarse crushers come in three types: jaw, cone, and impact. They can crush aggregate raw materials of varying hardness from low to high. Cone crushers are generally used for easily crushable materials with low hardness, while jaw and impact crushers can be selected for hard and difficult-to-crush raw materials. The following is a comparison table of their principles, functions, and applicable materials.

| Equipment type | Jaw type Aggregate Coarse Crusher (high hardness material) | Cone type Aggregate Coarse Crusher (high efficiency and energy saving) | Impact type Aggregate Coarse Crusher (excellent particle shape) |

| Applicable materials | High hardness materials such as granite and basalt | High hardness materials (such as iron ore, granite) | Medium and low hardness materials (such as limestone, dolomite) |

| Feed particle size | ≤1200mm (such as PE1200×1500 type) | ≤550mm (such as MC series single cylinder cone crusher) | ≤1200mm (such as MPF series) |

| Discharge particle size | 40-350mm (adjustable) | 5-60mm (fine crushing effect is better) | 5-50mm (cubic particles) |

| Output | 60-1160t/h (depending on the model) | 55-1850t/h (medium and high production capacity requirements) | 90-1550t/h (applicable to medium and low hardness) |

| Crushing method | Extrusion crushing | Lamination crushing | Impact crushing |

| Finished particle shape | More needle-shaped | Uniform particle shape | Many cubic particles, excellent particle shape |

| Energy consumption | Medium | Low (energy saving) | Medium |

| Maintenance cost | Low (simple structure) | Medium (hydraulic system maintenance) | High (frequent replacement of wear-resistant parts) |

| Investment cost | Low | High (large initial investment) | Medium |

| Main features | Large crushing ratio, deep V-shaped cavity to reduce blockage, simple maintenance | Hydraulically adjust the discharge port, high degree of automation, suitable for large production lines | Good particle shape, suitable for building material aggregates, low investment, but high maintenance costs |

What are the advantages of Aggregate Coarse Crusher?

Aggregate Coarse Crusher is specially designed for crushing various types of aggregates. It adopts optimized tool holder structure and alloy tools. It has a large crushing ratio, stable output, and uniform particle size. It is the core equipment for the production of building aggregates.

Large crushing ratio: With optimized tool holder design, a single machine can complete the work of traditional two-stage crushing, saving 30% of equipment investment.

Precise particle size: By replacing screens with different apertures, the output particle size can be accurately controlled between 5-100mm to meet various engineering standards.

Uniform particle size output: The material crushed by Aggregate Coarse Crusher is oval in shape, without sharp edges, and has a uniform particle size. It can provide raw materials for subsequent medium and fine crushing, or it can be used directly without secondary processing.

Easy maintenance: Hydraulic opening design, it only takes 30 minutes to replace the tool and screen, reducing downtime losses.

What is the principle of Aggregate Coarse Crusher?

Aggregate coarse crusher mainly crushes aggregates by extrusion, impact and splitting. Aggregates are evenly fed into the crushing chamber of jaw crusher or gyratory crusher through vibrating feeder. Aggregates are squeezed by moving jaw plate or gyratory hammer head, so that they are crushed between fixed jaw plates to form larger particles. The crushed aggregates are screened by vibrating screen. Aggregates that meet the particle size requirements enter the next process. Oversized materials are returned to the crusher for secondary crushing. Qualified aggregates are transported to medium and fine crushing equipment or finished product yard by conveyor belt.

Aggregate Coarse Crusher Parameters

| Model Specifications | Feed inlet size (mm) | Maximum feed particle size (mm) | Discharge particle size (mm) | Processing capacity (m³/h) | Electric motor (kW) | Weight (t) |

| PE-250×400 | 250×400 | 210 | 20-60 | 3-13 | 15 | 2.8 |

| PE-400×600 | 400×600 | 340 | 40-100 | 10-35 | 30 | 6.5 |

| PE-500×750 | 500×750 | 425 | 50-100 | 25-60 | 55 | 10.6 |

| PE-600×900 | 600×900 | 500 | 65-180 | 30-85 | 55-75 | 15.5 |

| PE-750×1060 | 750×1060 | 630 | 80-180 | 72-150 | 90-110 | 28 |

| PE-800×1060 | 800×1060 | 680 | 100-200 | 85-143 | 90-110 | 30 |

| PE-870×1060 | 870×1060 | 750 | 170-270 | 145-235 | 90-110 | 30.5 |

| PE-900×1060 | 900×1060 | 780 | 200-290 | 170-250 | 90-110 | 31 |

| PE-900×1200 | 900×1200 | 780 | 95-255 | 100-240 | 110-132 | 49 |

| PE-1000×1200 | 1000×1200 | 850 | 195-280 | 190-275 | 110-132 | 51 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-300 | 250-500 | 160 | 100.9 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 5-16 | 15 | 3.5 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 8-22 | 22 | 4.9 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 10-32 | 30-37 | 6.5 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 13-38 | 37 | 7.7 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 10-65 | 75 | 11 |

What are the uses of Aggregate Coarse Crusher?

Aggregate Coarse Crusher is mainly used in construction, road and bridge projects to crush large raw materials with a particle size of 500-1500mm into small aggregate particles. It can crush high-hardness granite and basalt; medium-hardness limestone and sandstone; and construction waste.

Construction aggregate production: crushing hard rocks such as granite, basalt, limestone, etc., to prepare coarse aggregates required for concrete and asphalt mixtures.

Roadbed cushion material processing: crushing large pieces of stone to a suitable particle size for laying foundation layers such as roads and railways.

Primary crushing in mines: after the stone is mined, the raw ore is initially crushed for easy transportation and subsequent processing.

| Aggregate type | Recommended model | Feed size (mm) | Discharge size (mm) | Output (T/H) | Power (KW) |

| Granite | Jaw + cone | ≤1200 | 25-40 | 150-300 | 132-250 |

| Limestone | Counterattack | ≤800 | 20-35 | 100-200 | 90-160 |

| River pebbles | Impact | ≤60 | 5-15 | 50-100 | 75-132 |

| Construction waste | Mobile | ≤600 | 0-40 adjustable | 90-180 | 101.5 |

Aggregate Coarse Crusher Customer Case

| Case name | Raw materials | Equipment | Discharge | Output | Benefit |

| Granite aggregate crushing project | Granite block, feed size ≤250mm | ZY-1 (J106) Mobile aggregate coarse crusher | 20-40mm roadbed aggregate | 280T/H | Compared with traditional production lines, energy consumption is reduced by 35% and labor costs are reduced by 50% |

| Limestone aggregate production line | Limestone ore, feed particle size ≤200mm | CSJ-120 aggregate coarse crusher + fine crusher combination | 5-15mm cement raw material | 120T/H | The particle size qualification rate is increased to 98%, and the equipment runs stably |

| Construction waste recycled aggregate project | Demolition concrete blocks, feed size ≤300mm | ZY-1 (E90) type aggregate coarse crusher | 10-30mm recycled aggregate | 160T/H | Realize resource utilization of construction waste, with a processing cost of only 8 yuan per ton |

Aggregate Coarse Crusher Manufacturer

MACHRISE Aggregate Coarse Crusher manufactures a variety of aggregate crushing products, including jaw crushers, gyratory crushers, impact crushers, cone crushers, and hammer crushers. These are suitable for coarse crushing of materials with varying hardness, and the crushing particle size is flexibly adjustable from 10-350mm. Processing capacity ranges from 50-2000t/h, suitable for the capacity requirements of aggregate production lines from small to large scale. For applications requiring frequent changes in usage scenarios, mobile models are available, allowing for free movement and eliminating site restrictions. Customization based on material characteristics and capacity requirements is supported, with prices starting from as low as $1000 USD. We also have a professional R&D team, and our products are certified with quality and CE certifications. We provide comprehensive pre-sales solutions and after-sales maintenance services.

Coarse crusher

Coarse crusher Minerals Coarse Crusher

Minerals Coarse Crusher

Ceramics Coarse Crusher

Ceramics Coarse Crusher