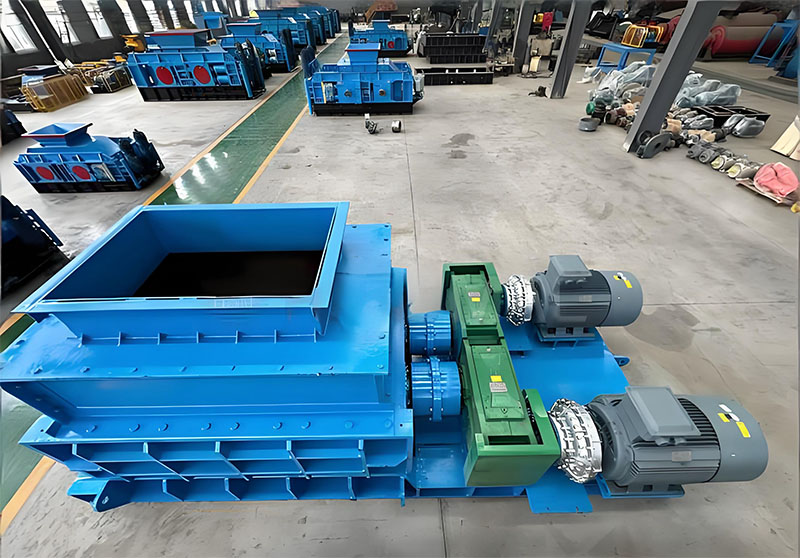

Double Roller Coal Coarse Crusher

Saturday January-31 2026 15:37:32

The Double Roller Coal Coarse Crusher is used to crush large lumps of coarse coal (300-500mm) into smaller granular coal. It crushes the coal to 30-100mm through shearing and compression by two parallel, counter-rotating rollers. The output particle size can be controlled by adjusting the gap between the two rollers. The processing capacity is 10-200 tons per hour, and it can be used to crush coal with medium hardness and low impurity content.

What types of Double Roller Coal Coarse Crusher are there?

Double Roller Coal Coarse Crushers can be divided into three types based on their roller surface shape: smooth, toothed, and grooved. Each type can crush different types of coal.

Smooth Double Roller Coal Coarse Crusher: The roller surface is smooth. It crushes coal through compression, producing relatively regular coal particles with less powder. It is generally used in applications requiring high uniformity of finished particle size and is suitable for crushing coals with lower hardness.

Toothed Double Roller Coal Coarse Crusher: The roller surface has evenly distributed teeth. In addition to compression, it also has a tearing effect. It is particularly effective for processing harder anthracite and lean coal, easily crushing large, hard coal pieces. However, the crushed particles will have slightly irregular shapes, making it suitable for coarse crushing stages where particle size requirements are not high.

Trough surface Double Roller Coal Coarse Crusher: The roller surface has annular grooves, which are suitable for highly viscous lignite. The grooves reduce the amount of coal sticking to the roller, avoid clogging, and ensure continuous crushing.

What are the advantages of the Double Roller Coal Coarse Crusher?

The Double Roller Coal Coarse Crusher crushes coal through compression, producing excessively fine particles with minimal over-grinding. Equipped with internal dust filters and a sealed structure, it reduces coal waste and dust pollution. A hydraulic spring overload protection system automatically adjusts to prevent damage when encountering uncrushable materials. The output coal particle size is controllable from 10-100mm, precisely controlled by adjusting the roller gap. It boasts a large processing capacity of up to 200 tons per hour and can be customized with different double roller sizes, motor functions, and dust collection devices to suit various coal crushing needs and application scenarios.

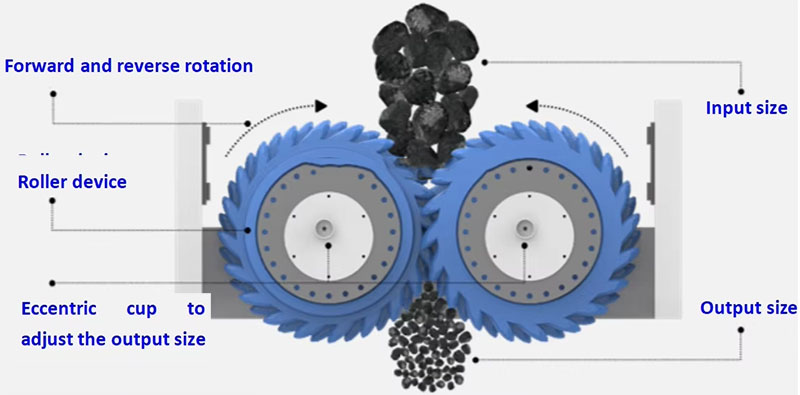

How does the Double Roller Coal Coarse Crusher work?

When a Double Roller Coal Coarse Crusher is in operation, coal enters the crushing chamber through the top feed inlet. The feed inlet typically has a guide plate to direct the coal between two opposing rotating rollers, preventing it from deviating and causing incomplete crushing. The two rollers are driven by a motor through a reducer, rotating in opposite directions. As the coal falls between the rollers, it is pulled towards the center by the friction of the rollers and simultaneously subjected to the squeezing action of the two rollers. During this process, the rollers automatically adjust the pressure according to the hardness of the coal. For particularly hard rock, some machines have roller retraction devices to prevent damage to the roller surfaces. After crushing, if the coal particle size is smaller than the distance between the two rollers, it will be discharged from the outlet below the rollers under gravity. Larger, uncrushed pieces will remain between the rollers until they are crushed to the required particle size before being discharged.

Double Roller Coal Coarse Crusher Parameters

What are the applications of a Double Roller Coal Coarse Crusher?

The Double Roller Coal Coarse Crusher can be used in various settings including coal mines, coal preparation plants, thermal power plants, and coal chemical enterprises. It can be used for both open-pit coal processing and underground pre-treatment. It efficiently crushes medium-hardness raw coal with a moisture content ≤15% and a compressive strength ≤100MPa, such as anthracite, bituminous coal, lignite, and lean coal. It can also successfully crush large pieces of coal containing small amounts of impurities. In the coal processing flow, it is mainly used for coarse crushing pre-treatment, breaking large raw coal pieces (within 800mm) into uniform 20-80mm pieces, providing raw material for subsequent fine crushing, screening, and washing processes.

Double Roller Coal Coarse Crusher Solution

A coal preparation plant in Southeast Asia needed to process lignite in its pretreatment project. The lignite was highly viscous, with an ash content of around 20%. The raw coal needed to be crushed from 50 cm to below 10 cm to facilitate subsequent jigging. The crushing process had to minimize dust generation to prevent coal dust pollution. The recommended solution was the Double Roller Coal Coarse Crusher. The trough surface reduces clogging from viscous coal. Equipped with a 37kW motor, it has a fixed particle size requirement, eliminating the need for frequent adjustments. The shim gap can be adjusted. A screen and iron removal device were added to the feed inlet to pre-filter small coal pieces and iron blocks. After six months of use, the customer reported a 90% reduction in clogging compared to their previous hammer crusher. The powder content of the crushed coal was below 5%, jigging efficiency improved by 15%, and coal recovery rate increased by 3%.

Coal Coarse Crusher

Coal Coarse Crusher