Biomass Coarse Crusher

It can crush large, irregular pieces of biomass raw materials such as wood and straw into smaller coarse particles or flakes, making it easier to provide raw materials for subsequent processing.

Price: $600-$9,800

Output: 5-40t/h

Inlet size: ≤1000mm

Outlet size: 1-150mm

What is Biomass Coarse Crusher?

Biomass Coarse Crusher can crush large pieces of biomass into smaller, more uniform particles. It uses high-speed rotating blades or hammers to crush various biomass raw materials to a particle size of 10-100mm, facilitating subsequent transportation, storage, and further processing. It can also crush large pieces of waste wood into granular wood chips or sawdust, with a processing capacity of 0.5-50 tons per hour. It is the preferred coarse crushing machine for industries such as biomass fuel and organic fertilizer production, providing pretreatment for the utilization of biomass resources.

Biomass Coarse Crusher is used for crushing powdery and granular biomass waste from wood processing plants. Biomass comes in many varieties, with high fiber content and high moisture content, thus requiring different crushers. Generally, high-fiber materials require shear crushing, hard nutshells require high-torque hammer crushers, and high-moisture materials require anti-clogging designs.

What types of Biomass Coarse Crusher are there?

Depending on the properties of the biomass feedstock being crushed, different models of Biomass Coarse Crusher are available, primarily including dual-shaft shear, single-shaft roller, hydraulic, and mobile types. When selecting a model, please determine the properties of the material, the output particle size, and the required production volume.

| Type | Applicable raw materials | Discharge size (mm) | Processing capacity (t/h) | Power (kW) | Main features |

| Biomass Coarse Crusher with dual-axis shearing | Tree roots, logs, bundles | 50-150 | 15-40 | 132-160 | High crushing force, anti-entanglement, processing complex raw materials |

| Single-axis roller-cut Biomass Coarse Crusher | Straw, branches, bulk materials | 20-100 | 5-20 | 45-110 | Simple structure, easy maintenance, low cost |

| Hydraulic Biomass Coarse Crusher | Tree stumps, building templates | 100-200 | 10-30 | 160-250 | High torque, suitable for extremely hard materials |

| Mobile Biomass Coarse Crusher | Garden waste, branches | 50-150 | 10-30 | 132-180 | High mobility, fast deployment |

What are the advantages of Biomass Coarse Crusher?

The Biomass Coarse Crusher utilizes wear-resistant alloy blades or hammers and a high-strength cavity structure, offering superior impact resistance and abrasion resistance. It efficiently crushes various biomass raw materials such as straw, branches, and sawdust, unaffected by material moisture content or fiber structure. Its crushing capacity is also high, reaching 50 tons per hour, with an adjustable output particle size range of 10-50mm. It can quickly process bulk materials and precisely control the crushing fineness by changing the screen. Furthermore, it boasts a high degree of automation, allowing connection to conveyor lines for automated assembly line operations. The machine is equipped with an overload protection system, ensuring safe and stable operation.

Performance comparison between Biomass Coarse Crusher and traditional crushing equipment

| Comparison items | Our biomass coarse crusher | Traditional crushing equipment | Advantages |

| Processing efficiency | Increase by more than 30% | Benchmark level | Higher output at the same power |

| Tool life | 600-800 hours | 300-400 hours | Reduce replacement frequency and cost |

| Energy consumption level | Reduce by 15-20% | Benchmark level | Long-term operating cost savings |

| Noise control | <85 dB | 90-95 dB | Improve working environment |

| Maintenance time | Reduced by 70% | Benchmark level | Improve equipment utilization |

| Intelligent monitoring | Real-time monitoring and early warning | No or basic monitoring | Reduce unexpected downtime |

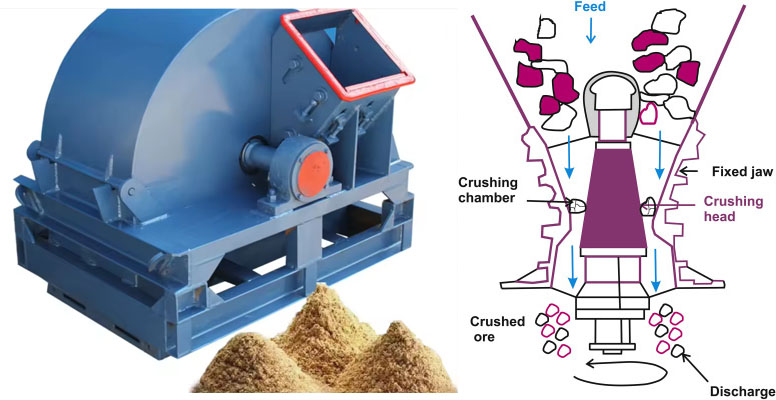

How does Biomass Coarse Crusher work?

When Biomass Coarse Crusher crushes biomass, raw materials such as straw and branches are manually put into the feed port and sent to the crushing chamber through the conveying device. The high-speed rotating blades or hammers impact and shear the materials, and the interaction between the tooth plate and the hammer further refines the materials. During the crushing process, materials that meet the particle size requirements are discharged through the screen, and larger particles are continued to be crushed until they meet the standards. The entire process can operate continuously, and the crushing particle size can be controlled by adjusting the screen aperture to adapt to the pretreatment requirements of different biomass raw materials and achieve efficient coarse crushing.

Biomass Coarse Crusher Parameters

| Parameter category | Dual-axis shearing type | Single-axis roller cutting type | Hammer type | Two-stage crushing system |

| Processing capacity (t/h) | 5-15 | 3-10 | 0.2-10 | 20-40 |

| Feed size (mm) | ≤1000 | ≤800 | ≤50 | ≤1000 |

| Discharge size (mm) | 50-100 (adjustable) | 80-150 | 1-10 (adjustable) | 20-50 |

| Motor power (kW) | 55-160 | 75-132 | 22-160 | 90+55 |

| Equipment weight (t) | 8-20 | 5-15 | 1-8 | 25-40 |

| Applicable raw materials | Whole bales of straw, branches | Tree stumps, hard wood | Loose straw, wood chips | Various mixed biomass |

What are the applications of Biomass Coarse Crusher?

Biomass Coarse Crusher can be used in industries such as bioenergy production, agriculture, forestry, organic fertilizer production, and environmental recycling to crush various biomass raw materials with a size not exceeding 1000mm. It can be used to crush agricultural waste such as corn stalks, rice husks, peanut shells, corn cobs, and sugarcane bagasse. Moreover, the crushed material can be directly used for organic fertilizer fermentation, biomass feed processing, or as a biomass fuel feedstock. It can also be used to process forestry waste such as branches, trunks, bark, and sawdust. The crushed products can be used for artificial board production, pulp manufacturing, biomass power generation, or biomass pelleting, etc. In short, it can crush large pieces of biomass raw materials into the required size for subsequent processing.

Biomass Coarse Crusher Customer Case

| Application Scenario | Feed Particle Size | Output | Finished Product Particle Size | Equipment Model | Remarks |

| Wood Processing Plant (Waste Wood) | ≤300mm (Branches, Bark) | 3-5 Tons/Hour | 30-50mm | BC-1000 | Moisture content <20%, used for fuel production |

| Straw recycling | <200mm (corn straw) | 2-3 tons/hour | 20-40mm | BC-800 | Dry straw, subsequently used for organic fertilizer production |

| Garden waste processing | <150mm (leaves and branches) | 1-2 tons/hour | 10-30mm | BC-600 | Mixed biomass for composting or incineration |

Biomass Coarse Crusher Manufacturer

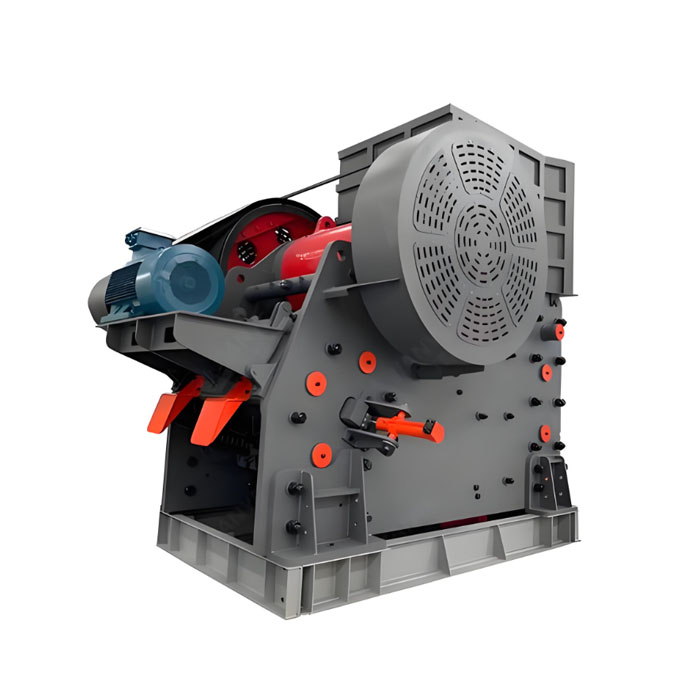

MACHRISE Machinery, a leading manufacturer of biomass crushers, Coarse Crusher, offers a variety of products for crushing biomass, including jaw crushers, hammer crushers, roller crushers, and impact crushers, with a processing capacity of up to 50 tons per hour. Suitable for crushing various biomass raw materials, from brittle and fibrous to those with moisture content, we support customized services, including adjustments to feed inlet size, blade configuration, and discharge particle size. We can also add dust collection devices, overload protection, and casters according to site requirements. As a factory direct seller, we have a complete production process and provide one-stop service, including installation, commissioning, technical training, and lifetime maintenance.

Coarse crusher

Coarse crusher Agricultural Waste Coarse Crusher

Agricultural Waste Coarse Crusher

Construction Debris Coarse Crusher

Construction Debris Coarse Crusher