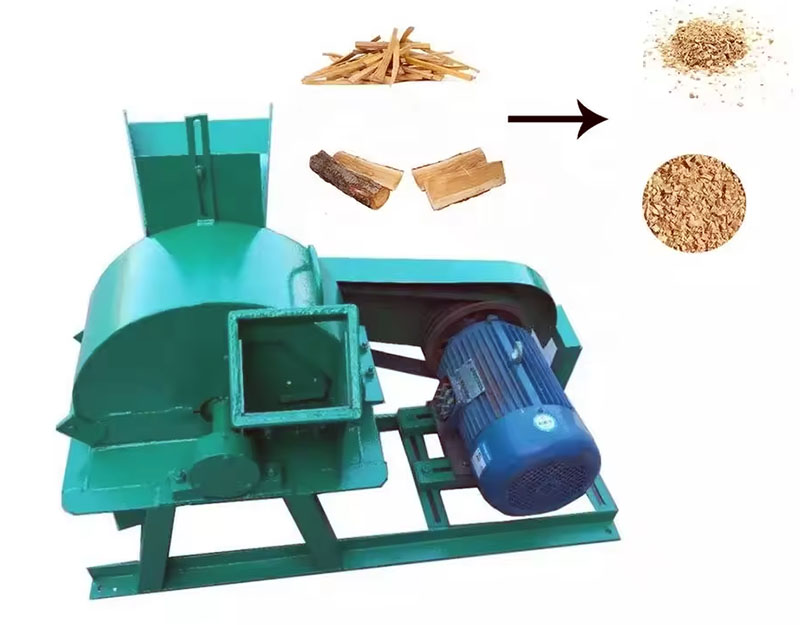

Agricultural Waste Coarse Crusher

It is a crushing equipment designed for processing agricultural waste such as crop straw, branches, livestock and poultry manure, and agricultural product processing scraps.

Price: $500-$9,500

Production: 1.2-2t/h

Feed size: ≤500mm

Discharge size: 95%≤50mm

What is the Agricultural Waste Coarse Crusher?

Agricultural Waste Coarse Crusher is a device for the preliminary crushing of agricultural waste such as straw, rice husk, corn cob, bagasse, etc. It adopts low speed and high torque drive, combined with high-strength cutter shearing and tearing action, to achieve rapid coarse crushing of large wastes, greatly improving the efficiency of subsequent composting, incineration or resource utilization. The equipment can crush agricultural waste to 10-40 mesh (particle size of about 0.425-2 mm), which is adjusted according to the material properties and equipment model. The output varies greatly depending on the model. Small equipment can produce 500-1000 kg per hour, medium-sized equipment can produce 1-3 tons per hour, and large equipment can reach more than 5 tons per hour, meeting the needs of agricultural waste treatment of different scales.

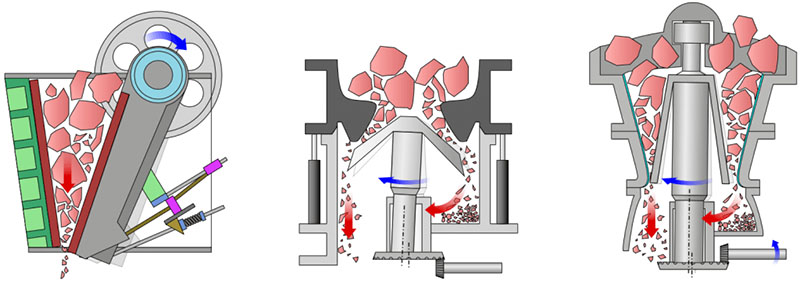

What types of Agricultural Waste Coarse Crusher are there?

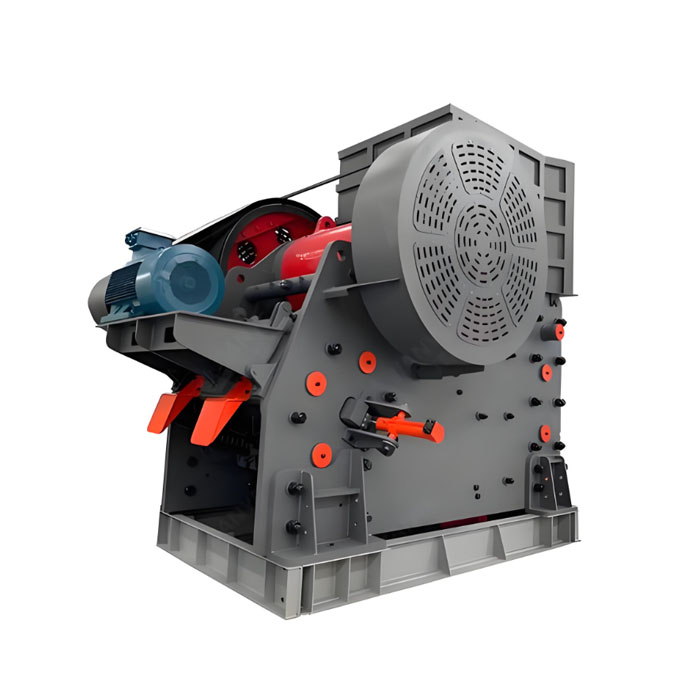

Agricultural Waste Coarse Crusher can be divided into three specifications: small (fine crushing), medium and heavy (jaw type). You can choose the appropriate model according to the crushing material and output requirements.

Light crusher (output 0.5-1t/h): suitable for small farms to process soft waste such as straw, fruit and vegetable residues

Medium crusher (output 1.2-2t/h): standard model, can process most agricultural waste, such as straw, fruit branches, etc.

Heavy crusher (output 2-5t/h): equipped with stronger power, suitable for processing wood waste and mixed materials with high fiber content

What are the advantages of Agricultural Waste Coarse Crusher?

The Agricultural Waste Coarse Crusher is specially designed for the characteristics of agricultural waste. The optimized blades and crushing chamber can effectively avoid entanglement and blockage problems. It adopts 30kw×2 motors with reducer drive to achieve high shear force crushing with low speed and high torque, which is both efficient and energy-saving. The particle size of the output material is uniform and controllable, and 95% of the crushed material has a particle size of ≤50mm, which is fully adapted to the subsequent processing process. In terms of durability, the bearings are sealed with six layers of waterproof and dustproof, and the cutters can be repaired multiple times, which significantly reduces maintenance costs. It is equipped with a PLC automatic control system, covering intelligent functions such as start, stop, reverse and overload automatic reverse. At the same time, it adopts a low-noise design and strictly controls the amount of dust generated, which fully complies with environmental protection standards and is an ideal choice for agricultural waste treatment.

How does the Agricultural Waste Coarse Crusher work?

The Agricultural Waste Coarse Crusher uses a dual-axis shearing crushing principle, using two sets of counter-rotating knife rollers to shear, tear and squeeze the material, so that large pieces of waste are crushed to the target size. The equipment is equipped with a screen to ensure uniform discharge and meet the needs of different subsequent processes.

Agricultural Waste Coarse Crusher Parameters

| Model | Feed size | Discharge size | Output (kg/h) | Power (kW) | Applicable materials |

| GDB-500 | ≤250mm | 50-200mm | 500-1500 | 22 | Straw, branches |

| GDL-750 | ≤500mm | 100-300mm | 1000-3000 | 37 | Big bales of straw, wood |

| GDF-400 | ≤200mm | 30-100mm | 300-800 | 15 | Livestock manure, organic waste |

What are the applications of Agricultural Waste Coarse Crusher?

Agricultural Waste Coarse Crusher can be widely used in various agricultural waste treatment scenarios. It can efficiently crush rice, wheat and other crop straw, corn cobs, sugarcane bagasse and other post-harvest residues, as well as peanut shells, rice husks and other agricultural product processing by-products, as well as fruit and vegetable picking residual branches and leaves, vines and weeds. These crushed materials can be used to make organic fertilizer raw materials, and realize resource utilization through composting and fermentation; they can also be used as pre-processing materials for biomass fuels, used in energy conversion fields such as straw power generation and biogas production; they can also be used as base materials for edible fungus cultivation, or as crude fiber for animal feed, effectively solving the problems of agricultural waste stacking and land occupation, incineration pollution, and promoting the development of agricultural circular economy.

What agricultural waste can be treated with the Coarse Crusher?

The Agricultural Waste Coarse Crusher can shred a variety of agricultural organic waste, including straw (corn, wheat, rice, etc.), vines, hay, branches, fruit shells, livestock and poultry manure, silage, sugarcane bagasse, cassava residue, cotton stalks, and peanut seedlings. It is suitable for feed processing, organic fertilizer production, and biomass fuel production.

The following are the relevant parameters for common agricultural waste shredding.

| Crushed Material | Crushed Particle Size (Feed) | Output (t/h) | Finished Product Particle Size (mm) | Recommended Equipment Type |

| Dry Straw (Corn, Wheat) | ≤300 mm (Whole Plant) | 1-5 | 5-30 | Hammer mill, disc mill |

| Silage, wet straw | ≤200 mm | 2-8 | 10-50 | Chain mill, high-moisture material mill |

| Branches, vines | ≤80 mm (diameter) | 0.5-3 | 10-40 | Dual-stage mill, vertical mill |

| Livestock and poultry manure (mixed material) | ≤100 mm (lump) | 3-10 | 5-20 | Chain crusher, double-stage crusher |

| Sugarcane bagasse, cassava residue | ≤150 mm | 2-6 | 5-15 | Vertical crusher, hammer mill |

| Peanut vines, cotton stalks | ≤200 mm | 1-4 | 10-30 | Disc crusher, hammer mill |

Agricultural Waste Coarse Crusher Customer Case

| Case Study | Application Scenarios | Feed Particle Size | Discharge Particle Size | Production Volume | Equipment Model/Features |

| Mulberry Branch Crushing in a Pakistani Agricultural Industry | Mulberry Branch Crushing for Mushroom Culture Preparation | Whole mulberry branches (diameter ≤5cm) | Wood chips (1-3cm) | 40 tons/day (continuous operation) | Customized pulverizer + autoclave system, fully automated processing |

| Straw pulverization project in Southeast Asia | Corn straw pulverization and return to fields to improve soil fertility | Compacted straw bales (1.2 x 2.1 x 1.5m) | 6-9cm | 4-6 tons/hour | GDB115 dual-shaft biomass pulverizer, 8-25 tons/hour processing capacity, PLC intelligent control |

| Rice straw return to fields in China | Early rice straw crushing and return to fields to increase soil organic matter | Whole rice straw (length <1.5m) | 5-10cm | 10 mu/hour (approximately 2-3 tons) | Harvester equipped with heavy-duty blades for integrated crushing and spreading |

| Straw processing in Vietnam | Corn straw and peanut shell crushing for feed/biomass fuel | Corn straw (diameter <2cm) | 2-12mm (adjustable) | 1-2 tons/hour | 50-50 hammer mill, automatic feed, compatible with electric/diesel engines |

Coarse crusher

Coarse crusher Pharmaceutical Materials Coarse Crusher

Pharmaceutical Materials Coarse Crusher

Construction Debris Coarse Crusher

Construction Debris Coarse Crusher