Ceramics Coarse Crusher

It can break large or small particles of brittle or medium-low hardness ceramic raw materials into particle sizes that meet the requirements of subsequent processing through extrusion, impact and other methods.

Price: $600-$9,500

Feed size: greater than 300mm

Discharge size: 5-20mm

Processing capacity: 5-50t/h

What is Ceramics Coarse Crusher?

Ceramics coarse crusher is used to crush large or irregular ceramic raw materials before ceramic production and processing. They reduce the volume of the raw materials through mechanical extrusion and impact, providing materials of suitable particle size for subsequent fine crushing and grinding processes. They can crush ceramics up to 300mm in size, and the output particle size can be adjusted by the sieve aperture, generally between 20-50mm, with a crushing capacity of 5-50 tons per hour.

Ceramic coarse crushers can be used to crush different raw materials in ceramic production processes. There are fine crushers for brittle ceramics; jaw crushers or hammer crushers can be used for larger, more abrasive, and harder ceramics; and for ceramics with large production sizes and high demand, impact crushers can be used for high crushing efficiency and output.

What types of Ceramics Coarse Crusher are there?

The Ceramics Coarse Crusher offers jaw, twin-roll, and impact crushers for crushing large ceramic materials. Fine crushers are required for crushing smaller ceramic materials. The appropriate model is selected based on the characteristics of the material being crushed.

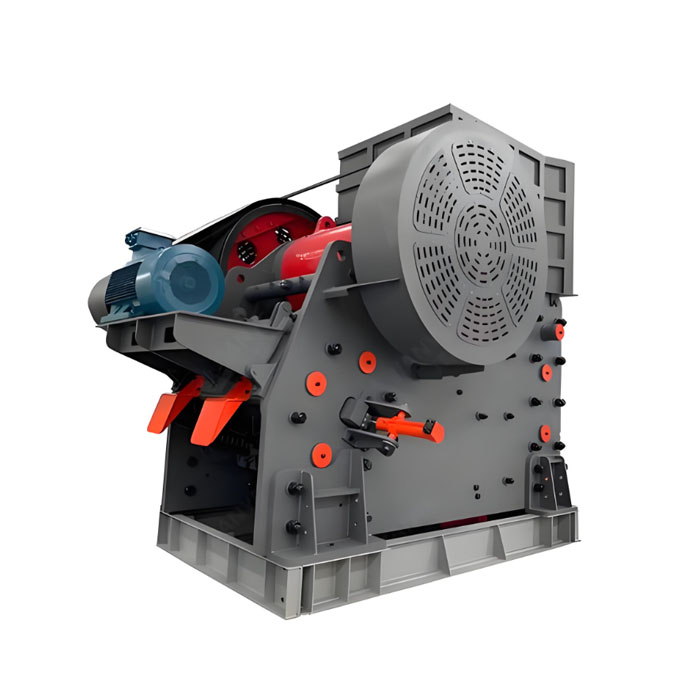

Jaw Ceramics Coarse Crusher: It is suitable for medium-hard to hard ceramic materials (such as quartz, feldspar, and kaolin) with a particle size of 40-110mm. It effectively crushes large lumps, resulting in a finished product particle size of 0.5-10mm and a production capacity of up to 300 tons.

Twin-Roll Ceramics Coarse Crusher: It utilizes two counter-rotating rollers for compression and shearing. It is suitable for feed materials ≤30mm in size, such as clay and ceramic waste. It is particularly suitable for materials requiring high purity (such as electronic ceramics). It can discharge the material from the side or bottom, with a small production capacity of up to 5 tons and a finished product particle size of 0.15-3mm.

Impact Ceramic Coarse Crusher: It can be used to crush large and small ceramic raw materials. Using a high-speed rotating rotor to impact the material, it is suitable for medium-hard, brittle ceramic raw materials (such as ceramic waste and basalt), with a finished product size of 3-10mm.

Fine Crusher: Suitable for crushing small ceramic raw materials with a feed size of ≤30mm, with a finished product size of 5mm-20μm and a production capacity of up to 500kg.

What are the advantages of Ceramics Coarse Crusher?

The Ceramics Coarse Crusher, made of high-strength, wear-resistant materials, can crush brittle to high-hardness ceramics, exhibiting excellent impact resistance and low abrasion resistance. It can handle ceramic raw materials with a feed size of ≤300mm, and the output particle size can be flexibly controlled between 20-50mm by adjusting the screen aperture size, with a processing capacity of 10-50 tons per hour. For processing large ceramic pieces with high output requirements, a jaw crusher can be selected; it can crush any hard ceramic. Furthermore, depending on the application, side discharge or bottom discharge can be selected, and parameters such as feed inlet size and motor configuration can be customized to meet specific needs.

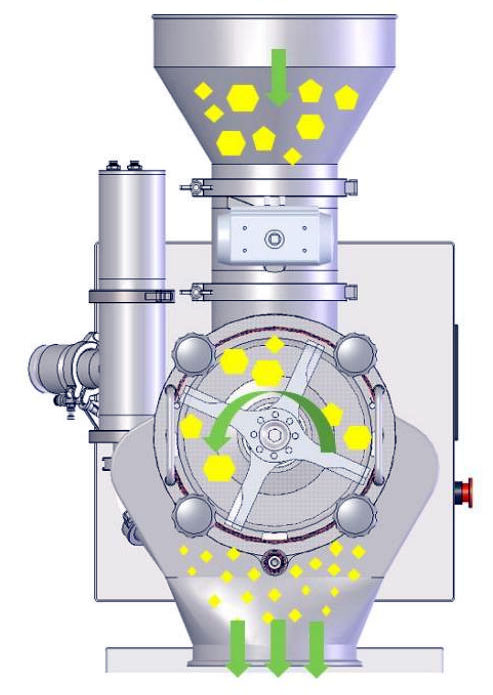

What is the principle of Ceramics Coarse Crusher?

When the Ceramics Coarse Crusher is in operation, the ceramics to be crushed enter the crushing chamber through the feed inlet. Under the shearing and impact of the high-speed rotating blades and the fixed blades, the ceramics are repeatedly crushed. After crushing, the material that meets the size requirements passes directly through the screen and is discharged from the discharge outlet. The material that does not meet the specifications remains in the crushing chamber and continues to be crushed until it meets the requirements.

Ceramics Coarse Crusher Parameters

| Parameter name | CSJ-200A | CSJ-300B | CSJ-400C |

| Motor power | 15kW | 22kW | 37kW |

| Processing capacity | 1-5t/h | 1.5-2.5t/h | 1-50t/h |

| Feed particle size | ≤80mm | ≤60mm | ≤100mm |

| Discharge particle size | 20-100 mesh | 100-300 mesh | 10-50 mesh |

| Blade speed | 1200rpm | 1500rpm | 1000rpm |

| Equipment weight | 850kg | 1200kg | 1800kg |

| Overall dimensions | 1500×800×1800mm | 1800×900×2000mm | 2200×1200×2500mm |

What are the applications of Ceramics Coarse Crusher?

Ceramics Coarse Crusher can be used to crush large ceramic raw materials up to 300mm into small particles or coarse powder up to 80mm. It is commonly used in industries such as building ceramics, industrial ceramics, and electronic ceramics to crush various types of ceramic materials, such as feldspar, quartz, kaolin, alumina, limestone, dolomite, construction waste, silicon nitride, barium titanate, silicon carbide, zirconium oxide, and other hard ceramic waste, bone china, and reinforced ceramics.

Ceramics Coarse Crusher Customer Case

| Application Scenarios | Feed Particle Size | Discharge Particle Size | Production Range | Applicable Features |

| Laboratory/Small Batch | ≤60mm | 0.5-20mm | 350kg/h | Dual Crushing, Dust-Proof Design |

| Waste Recycling/High-Purity Materials | ≤30mm | 0.15-3mm | 500kg/h-2T/h | Pollution-Free, Good Sealing |

| Glaze/Thermosensitive Materials | ≤50mm | 3-10mm (Coarse Crushing) | 500-1000kg/h | Ultra-fine Crushing Optional, Energy Saving |

| Ultra-fine Crushing of Billets | ≤90mm | 100 mesh - 5mm | 2-5T/h | Three-stage crushing, high crushing ratio |

Ceramics Coarse Crusher Price

The price of a Ceramics Coarse Crusher ranges from $500 to $95,000. Many factors influence the price, such as type, crushing fineness, output, output particle size, and power configuration. The type of ceramic being processed also affects the material used – high-wear-resistant alloy steel or special steel – which determines the machine's wear resistance. Some machines also require additional functions such as iron removal or dust removal on top of the standard machine, which further increases the cost.

Ceramics Coarse Crusher Manufacturer

MACHRISE Ceramics Coarse Crusher manufacturers offer a variety of crushers for ceramics, including fine crushers, jaw crushers, double-roll crushers, hammer crushers, and cone crushers. These crushers can be used for coarse crushing of ceramic raw materials ranging from brittle to high-hardness, high-volume applications. The crushing chamber and other structures are constructed with wear-resistant materials such as high-manganese steel and high-chromium alloys, and feature thickened liners. They can even crush hard, highly abrasive ceramic raw materials, with a processing capacity of up to 300 tons. The crushing particle size can be customized with 20-50mm screens according to requirements. Furthermore, customized models and tooth profile designs can be created to meet specific needs such as feed particle size, output, discharge particle size, and application scenarios.

Coarse crusher

Coarse crusher Agricultural Waste Coarse Crusher

Agricultural Waste Coarse Crusher

Construction Debris Coarse Crusher

Construction Debris Coarse Crusher