Vertical Packaging Machine for milk powder

the single-channel model of Vertical Packaging Machine for Milk Powder can reach 20-60 bags/minute, and the multi-channel model can achieve a maximum capacity of 400 bags/minute. The price varies depending on the configuration. The basic single machine price is about US$2,199-2,799, while the fully automatic production line with integrated advanced functions such as vacuuming, multi-column packaging, and online detection costs about US$50,000. Capacity: 200-400 bags/minute Packaging specifications: 50g-2000g/bag

Packaging material: composite film/aluminum foil, thickness 0.08-0.12mm Accuracy: ±1% weighing error Power supply: 380V/50Hz, power 5.5kW Air source: 0.6MPa, air consumption 0.3m³/min Dimensions: 2000×1200×1800mm Weight: about 1500kg Function: automatic metering, bag making, filling, sealing, coding

What is Vertical Packaging Machine for milk powder?

Vertical Packaging Machine for milk powder is designed for powdered dairy products and can handle multiple categories such as whole milk powder, skim milk powder, infant formula milk powder, middle-aged and elderly nutritional milk powder, special medical formula milk powder, etc. Its core structure consists of a spiral metering system, a vertical bag making module, a nitrogen filling and preservation device, an intelligent temperature control sealer, and a touch operation terminal. The spiral metering system is driven by a servo motor to achieve accurate weighing within the range of 10-3000 grams, with an error control within ±0.3%; the vertical bag making module supports the production of various bag types such as flat bags, three-dimensional bags, and handbags, with a bag size range of 70-250 mm in width and 100-320 mm in length.

In terms of packaging speed, the single-channel model of Vertical Packaging Machine for Milk Powder can reach 20-60 bags/minute, and the multi-channel model can achieve a maximum capacity of 400 bags/minute. The price varies depending on the configuration. The basic single machine price is about US$2,199-2,799, while the fully automatic production line with integrated advanced functions such as vacuuming, multi-column packaging, and online detection costs about US$50,000.

What are the functional features of Vertical Packaging Machine for milk powder?

Vertical Packaging Machine for milk powder has multiple functional advantages. In view of the characteristics of milk powder that it is easy to absorb moisture and agglomerate, the equipment adopts a closed spiral feeding system to reduce the contact between the material and the air; some models are equipped with a nitrogen filling function to reduce the contact between milk powder and oxygen, which is suitable for functional milk powder that is sensitive to oxidation; the equipment supports a variety of packaging materials, such as aluminum foil composite film, PE/PP plastic film, etc., to ensure moisture-proof, anti-oxidation and extend the shelf life; the PLC intelligent control system has functions such as fault self-detection, automatic alarm for lack of material, and automatic detection of bag length, which greatly improves the operation stability and convenience of operation.

Vertical Packaging Machine for milk powder parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Vertical Packaging Machine for milk powder bag features

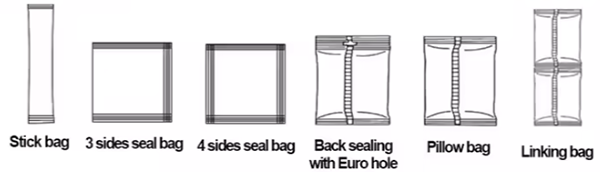

Vertical Packaging Machine for milk powder supports a variety of bag types, including three-side sealed bags, four-side sealed bags, back-sealed bags, and gusseted bags. The choice of bag type should be determined according to the target market and storage characteristics of the milk powder. For middle-aged and elderly milk powder and instant milk powder, it is recommended to use back-sealed bags or gusseted bags, which are convenient for standing and beautiful; infant milk powder often uses three-side sealed small bags or independent packaging bags to ensure accurate mixing volume each time and improve the hygiene level. The equipment supports a variety of composite film materials, such as aluminum-plastic film, PE film, degradable environmentally friendly film, etc., which can meet the different needs of moisture-proof, anti-oxidation, and light-proof, and extend the shelf life of milk powder.

Vertical Packaging Machine for milk powder bag sample

Vertical Packaging Machine for milk powder price

Vertical Packaging Machine for milk powder price The basic model supports 20-60 bags/minute, and the high-end model has servo motor and PLC control, with higher precision and more comprehensive functions.

Basic configuration model: power is about 2-5.5kW, packaging speed is 20-60 bags/minute, supports 50-2000g/bag capacity, can make flat bags and three-dimensional bags, equipped with spiral metering, heat sealing, and printing batch number functions, and the price is about 60 million to 10,000 US dollars.

High-end intelligent model: using servo motor, PLC control, touch screen operation, supporting a variety of bag types (including handbags), packaging accuracy ≤±0.3%, with automatic correction, dust removal, and metal detection functions, the price is about 10,000-20,000 US dollars.

Vertical Packaging Machine for milk powder Main options

Vertical packaging machine for milk powder can be customized according to characteristics: servo screw metering for poor fluidity, vibration bag maker for easy agglomeration, enhanced heat sealing for high-demand milk powder, PLC control for complex formula, and multi-column modules for small-dose packaging.

Feeding system: For milk powder with poor fluidity, such as milk powder with probiotics, it is recommended to use a servo motor-driven screw metering system to ensure accurate filling; ordinary milk powder with good fluidity can use gravity metering.

Bag maker: For milk powder that is easy to agglomerate, such as whole milk powder, a bag maker with a vibration device can be selected to prevent powder accumulation from affecting the sealing quality.

Sealing device: For high-demand milk powder, such as organic milk powder, it is recommended to use an enhanced heat sealing system to ensure sealing and avoid moisture.

Control system: For milk powder with complex formula, such as segmented infant milk powder, a PLC system with a touch screen can be selected to facilitate quick switching of packaging parameters.

Additional functions: If small-dose packaging is required, such as 10-50g samples, a multi-row packaging module can be added.

Vertical Packaging Machine for milk powder selection guide

Select Vertical Packaging Machine for milk powder for different types of milk powder: Infant formula milk powder requires high-end models to ensure cleanliness and precision, and adult milk powder uses standard equipment; the difference in fluidity matches the corresponding metering system, and the production capacity selects single-channel or multi-channel models according to the scale of the enterprise.

Types of milk powder: If it is infant formula milk powder, it is recommended to select high-end models with high cleanliness level, precise feeding and nitrogen filling; adult milk powder or ordinary nutritional milk powder can use standard equipment.

Fluidity matching: High-fluidity milk powder (such as skim powder) can choose screw metering, and low-fluidity milk powder (such as formula powder containing probiotics) needs to be equipped with a vibrating screen + screw composite system.

Capacity planning: Startup brands are recommended to choose single-channel models (20-60 bags/minute), and mature companies can consider 4-channel models (400 bags/minute) or modular production lines.