Vertical Packaging Machine for Nuts

Vertical Packaging Machine for Nuts equipment is usually equipped with a vibrating plate or spiral metering system to ensure accurate metering. In terms of price, the Vertical Packaging Machine for Nuts is priced at about $5,000-$10,000, depending on whether it is equipped with additional functions such as automatic feeder, coder, nitrogen filling, etc. Scope of application: packaging of granular materials such as nuts, dried fruits, snacks, etc. Packing speed: 30-80 bags/minute Bag specifications: back seal, three-side seal, four-side seal Packing materials: composite film, aluminum foil film, paper bag, etc Packing weight: 10g-1000g Power supply: 220V/50Hz Power: 1.5KW Control system: PLC touch screen control

What is Vertical Packaging Machine for Nuts?

Vertical Packaging Machine for Nuts is usually between 20g and 2000g, and the output can reach 30-60 bags/minute, depending on the packaging specifications and the degree of automation. Nut materials usually have the characteristics of irregular shapes, different sizes and easy to break, so the equipment is usually equipped with a vibrating plate or spiral metering system to ensure accurate metering. Structurally, the Vertical Packaging Machine for Nuts adopts a stainless steel body, meets food-grade hygiene standards, and is equipped with a PLC control system and a touch screen operation interface for easy parameter adjustment. In terms of price, the Vertical Packaging Machine for Nuts is priced at about $5,000-$10,000, depending on whether it is equipped with additional functions such as automatic feeder, coder, nitrogen filling, etc.

How does the Vertical Packaging Machine for Nuts work?

When the Vertical Packaging Machine for Nuts works, the nut material is first poured into the hopper of the feeding system, and the material is evenly conveyed to the metering device through a vibrating feeder or a screw feeder. The metering device accurately weighs the required amount of nuts according to the preset packaging weight, and then feeds it into the bag former. At the same time, the packaging film is formed into a bag shape under the action of the bag former, and the nuts fall into the bag. Then, the sealing mechanism heat-seals or cold-seals the bag to complete the sealing action, and finally the packaged bag is cut off from the packaging film by a cutter to complete the entire packaging process.

Features of Vertical Packaging Machine for Nuts

Vertical Packaging Machine for Nuts has a small footprint, suitable for production line layout with limited space, and is easy to link with other equipment. High-precision metering function, controlled by servo motor, metering error range controlled within ±1%; supports multiple packaging styles such as back seal, three-side seal, four-side seal, etc., to achieve multi-functional packaging; uses PLC combined with touch screen intelligent operating system, can store multiple production formulas, easy to switch production specifications; the whole machine is made of food-grade stainless steel, in line with GMP standards, durable and easy to clean and maintain.

Vertical Packaging Machine for Nuts Parameters

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

Vertical Packaging Machine for Nuts Price

The price of Vertical Packaging Machine for Nuts depends on factors such as structure, function, and degree of automation. Semi-automatic models are suitable for small production lines, fully automatic models have comprehensive functions, and customized models have high output.

Semi-automatic models: simple structure, mechanical transmission, manual assistance for feeding or sealing; basic functions, support quantitative filling and heat sealing; low output (10-30 packs/minute), suitable for small and medium-sized production lines or start-ups. Price $5,000-$10,000.

Fully automatic model: modular structure, integrated servo motor, PLC control system; comprehensive functions, including automatic metering, bag making, nitrogen filling, labeling, etc.; output of 50-100 bags/minute, suitable for continuous large-scale production. The price range is $12,000-$20,000.

High-end customized model: stainless steel body + intelligent sensor, support automatic boxing or robot palletizing; expandable functions (such as multi-specification switching, data traceability); output exceeds 120 bags/minute, meeting high-precision and flexible production needs. The price is around $25,000.

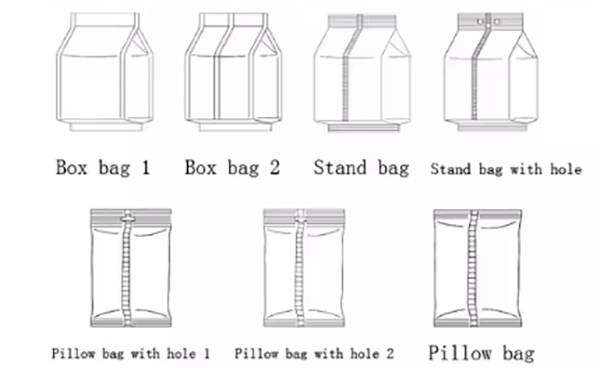

Bag shape of Vertical Packaging Machine for Nuts

Vertical Packaging Machine for Nuts can produce a variety of bag shapes, including three-side sealed bags, four-side sealed bags, self-supporting bags and zipper bags. Three-side sealed bags have a simple structure and low cost; four-side sealed bags have better sealing performance and are suitable for nuts with high freshness requirements; self-supporting bags can be placed upright for easy display and sales; zipper bags are convenient for consumers to open and seal multiple times to keep the nuts fresh. Different types of packaging bags often use different materials, such as aluminum foil bags, composite films, polyethylene (PE), polypropylene (PP), etc., which can provide the best protection performance according to the needs of the product, and can also improve the aesthetics and functionality of the packaging.

Functions of Vertical Packaging Machine for Nuts

Vertical Packaging Machine for Nuts supports a variety of metering methods, including volumetric filling (suitable for materials with uniform particles), weighing filling (accuracy up to ±0.5%) and counting filling (for quantitative particle packaging), to meet the metering needs of different nut varieties. Three process options are provided in the sealing link: heat sealing (temperature adjustable range 100-300℃), ultrasonic sealing (suitable for fragile nuts) and cold sealing (for heat-sensitive materials). Through the PLC control system, a number of automatic detection functions are integrated, including photoelectric sensor shortage alarm, real-time temperature PID control and fault code self-diagnosis system. In addition, the equipment can be equipped with a nitrogen replacement device, which significantly extends the shelf life of nuts through the automatic vacuum-nitrogen filling cycle process.

Application of Vertical Packaging Machine for Nuts

Vertical Packaging Machine for Nuts is used in food processing plants, nut roasting plants, snack food companies, e-commerce packaging centers and other fields, and is particularly suitable for products that require fast packaging and high hygiene standards. In addition to nuts, this equipment can also be used for the packaging of granular materials such as coffee beans, cashews, candies, grains, pet food, nut energy bars, puffed foods, etc. It has strong adaptability and a wide range of applications.

Vertical Packaging Machine for Nuts Supplier

Our factory has mature technical research and development capabilities, and can provide high-speed metering, precise filling and multi-specification switching functions according to the characteristics of the nut industry, and adapt to different product types such as shelled, shelled, and broken particles. In terms of service, our factory supports customized solutions, including packaging size, moisture-proof composite film and other material selection and automated production line linkage. Our factory also provides material trial machine services. The quality of the equipment strictly meets food-grade safety standards, uses stainless steel contact parts and easy-to-clean design to ensure hygiene, and is equipped with a complete after-sales technical support system.