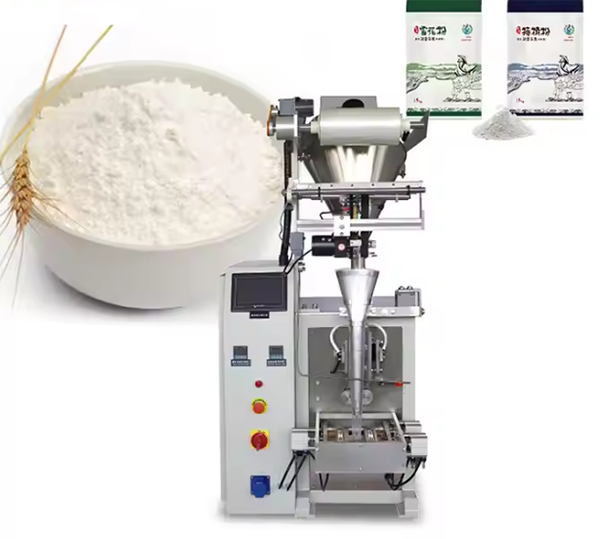

Vertical Packaging Machine for Flour

Vertical Packaging Machine for Flour is designed for automatic packaging of powdered materials, especially for flour products. Flour has the characteristics of good fluidity, easy moisture absorption and easy agglomeration. the price of equipment varies significantly due to production capacity and configuration. The price of Vertical Packaging Machine for Flour is about US$2,000-10,000. Packaging speed: 30-60 bags/minute (adjustable) Feeding method: spiral feeding/gravity induction Bag size: 100-300mm long, 80-200mm wide Applicable bag type: pillow bag, pin bag, four-side seal Applicable materials: flour, starch, corn flour, milk powder and other powdered materials

What is Vertical Packaging Machine for Flour?

Vertical Packaging Machine for Flour is designed for automatic packaging of powdered materials, especially for flour products. Flour has the characteristics of good fluidity, easy moisture absorption and easy agglomeration. Flour can be divided into high-gluten flour, medium-gluten flour, low-gluten flour and whole wheat flour. Different types of flour have high requirements on the sealing, dustproof and metering accuracy of the equipment when packaging. The output of flour is usually 20-80 bags/minute, and common equipment models can package 300-1000 kg per hour. In terms of price, the price of equipment varies significantly due to production capacity and configuration. The price of Vertical Packaging Machine for Flour is about US$2,000-10,000.

Vertical Packaging Machine for Flour adopts an automated workflow: flour first enters the storage bin through spiral conveying or gravity flow, and then is accurately measured by a screw or electronic scale (such as 5kg, 10kg, 25kg, etc.); the packaging film is made into a vertical bag shape by a former and heat-sealed, and the measured flour is filled into the bag through the feeding port; the bag mouth is sealed by heat sealing or seam sealing to prevent moisture and leakage, and the final product is sent out by a conveyor belt for subsequent boxing or palletizing.

What are the benefits of Vertical Packaging Machine for Flour?

The structural design of Vertical Packaging Machine for Flour is made of stainless steel, which meets the food hygiene standards, has dust and moisture resistance and is easy to clean. In terms of high output, the packaging speed can reach 5-60 bags/minute according to the model, which can meet the production needs of different scales. It is suitable for a wide range of materials, not only for flour, but also for powdered materials with good fluidity such as starch, milk powder, and sugar. It has a high degree of automation, equipped with a PLC control system and a touch screen operation interface, which is convenient for parameter adjustment and has a fault alarm function. At the same time, the packaging accuracy is also extremely high, using high-precision sensors and servo motors, and the error can be controlled within ±1%.

Vertical Packaging Machine for Flour Parameters

| Model | Measuring range | Packaging speed | Accuracy | Power | Applicable flour type |

| LFP-500 | 100g-5kg | 30-100 bags/min | ±0.5% | 2.5KW | Wheat flour, starch |

| LFP-1000 | 5kg-25kg | 15-60 bags/min | ±0.2% | 5KW | Bread flour, grain flour |

| LFP-2000 | 25kg-50kg | 2-30 bags/min | ±0.1% | 7.5KW | Industrial flour |

What is the price of Vertical Packaging Machine for Flour?

The price of Vertical Packaging Machine for Flour varies depending on the type of equipment, applicable materials, functions and structures. The following are the prices of vertical powder packaging machines and spiral conveyor powder packaging machines.

Vertical powder packaging machine

Structure: It consists of a feeding system (vibrating disc or screw), a metering device (volumetric or weighing), a bag making mechanism, a heat sealing device and a control system.

Function: Automatically complete metering, bag making, filling and sealing, suitable for fine powders such as flour, milk powder, etc., with high accuracy (±1%-2%).

Application: Small bag packaging (such as 1kg-5kg) in food, chemical and other industries.

Price: Basic models are about $5,000-$10,000, and high-precision models can reach $15,000.

Spiral conveyor powder packaging machine

Structure: It uses a spiral propeller to feed the material, equipped with a weighing sensor, a PLC control system and an automatic bag clamping device.

Function: It is suitable for powders with poor fluidity (such as additives), with higher accuracy (±0.5%-1%), and can handle large volumes (10kg-50kg).

Application: Heavy packaging in building materials, feed and other industries. Price: about $12,000-$25,000, with high-end models exceeding $30,000.

Vertical Packaging Machine for Flour Application

Vertical Packaging Machine for Flour is suitable for automated packaging of various flours, optimized for different characteristics: high-gluten flour particles are coarse and easy to clump, the machine uses a strong power spiral feed to ensure smooth filling; medium-gluten flour has good fluidity and is suitable for high-speed and accurate metering; low-gluten flour has a fine texture, and the gentle feeding system avoids compaction; whole wheat flour contains bran and is easy to generate dust, and the equipment is equipped with a dustproof seal design to reduce waste.

Vertical Packaging Machine for Flour is also used in other fields. In the food industry, it is suitable for quantitative packaging of powdered foods such as flour, starch, milk powder, and seasoning powder to ensure hygiene and sealing; in the baking and catering field, it can provide small-sized pre-packaged flour for bakeries and restaurants to improve packaging efficiency and reduce waste; in terms of industrial raw materials, it can be used to package building materials powder (such as putty powder), chemical powder, etc., to meet moisture-proof and dust-proof requirements; in the agriculture and feed industry, it is suitable for automatic packaging of agricultural powders such as feed and fertilizer, supporting large-capacity requirements. The equipment is suitable for a variety of bag types (such as back seal, four-side seal), suitable for small, medium and large-scale production lines.

How to choose Vertical Packaging Machine for Flour?

When choosing a Vertical Packaging Machine for Flour, the following key factors should be considered comprehensively: First, considering the high fineness and hygroscopicity of flour, it is recommended to give priority to models equipped with dust removal devices or vacuum feeding systems to ensure smooth transportation; secondly, it is necessary to confirm whether the equipment is compatible with common packaging materials such as PE film and composite film; at the same time, according to the actual production capacity requirements (such as 10-50 bags/minute), choose a model that matches the speed, and ensure that the equipment supports different packaging sizes such as 1kg-50kg; finally, a brand supplier with a good market reputation should be selected to obtain stable equipment performance and reliable after-sales maintenance support to ensure long-term production efficiency.