Vertical Form Fill Seal Packaging Machines

Vertical Form Fill Seal Packaging Machines , The packaging speed is usually 30-80 bags/minute, and the output is 1800-4800 bags/hour. In terms of price, the basic model is about $4,000-$6,000, the mid-range model is $8,000-$12,000. Packaging Speed: 20–80 bags/minute

Bag Width Range: 80–250mm

Bag Length Range: 100–400mm

Power Supply: AC220V/50Hz

Applicable Materials: Granules, Powders

What are Vertical Form Fill Seal Packaging Machines?

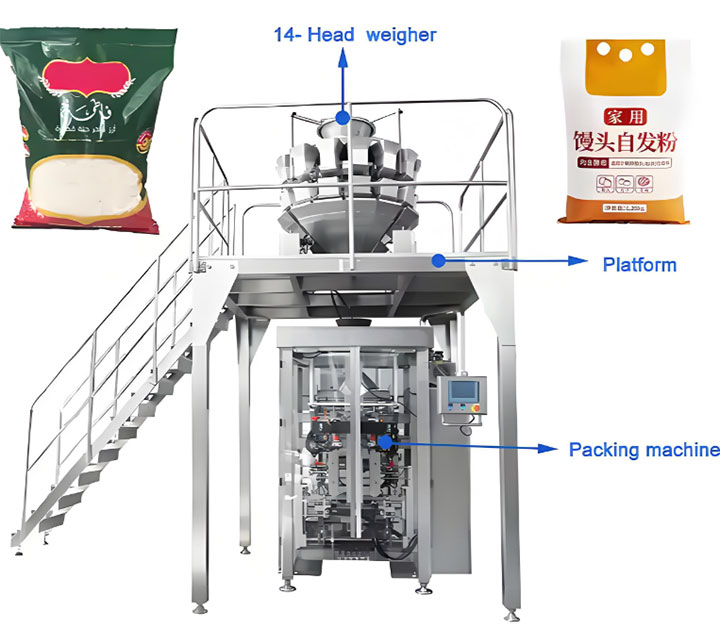

Vertical Form Fill Seal Packaging Machines utilize a vertically formed film roll, automatically metering and filling, and sealing and cutting process to achieve continuous, high-speed packaging. Combining a vertical structure, automatic bag forming, precise filling, and efficient sealing, these machines are suitable for a variety of materials, including granules, powders, liquids, and pastes. Packaging speeds typically range from 30–80 bags/minute, with outputs reaching 1,800–4,800 bags/hour, providing flexibility to meet diverse production needs. In terms of price, basic models range from approximately $4,000 to $6,000, mid-range models from $8,000 to $12,000, and high-end multi-functional models from $15,000 to $20,000. A complete automated production line costs approximately $30,000, offering both high cost-effectiveness and the advantages of automation.

What are the advantages of Vertical Form Fill Seal Packaging Machines?

The outstanding advantage of Vertical Form Fill Seal Packaging Machines lies in their modular configuration. The appropriate metering system can be selected to meet different packaging needs, such as screw-type for powders, electronic scales for granules, and liquid pumps for oils or pastes. Furthermore, various auxiliary functions such as ribbon coding, cursor positioning, and nitrogen filling systems can be added to achieve personalized packaging goals.

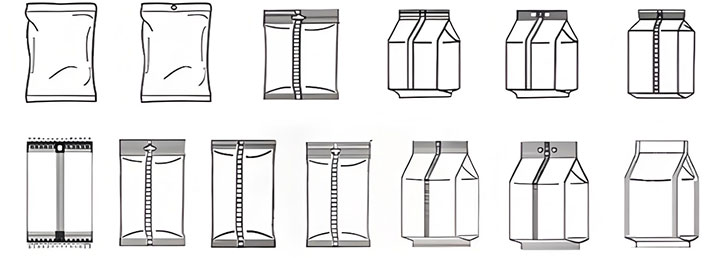

In terms of bag formats, VFFS machines can produce pillow bags, three-side seal bags, four-side seal bags, and gusset bags, adapting to different brand images and market needs. Bag type switching can be achieved by simply replacing the former and adjusting parameters, saving time and efficiency. Bag materials include single-layer film, composite film, and aluminum foil, meeting specific requirements such as moisture resistance, light protection, and breathability.

VFFS packaging machines integrate the three core processes of forming, filling, and sealing, achieving fully automated operation. Their high-speed operation (capable of processing hundreds of packages per minute) significantly shortens production cycles, making them particularly suitable for high-volume production applications such as food and pharmaceuticals. For example, in snack packaging, the machine can quickly convert from roll film to finished bags, meeting market demand for high production capacity.

Vertical Form Fill Seal Packaging Machines General Technical Specifications

| Model | VP-420 | VP-520 | VP-620 | VP-730 | VP-800 | VP-1050 |

| Bag Size | (L)70-300mm (W)60-200mm | (L)80-350mm (W)100-250mm | (L)80-400mm (W)140-350mm | (L)200-450mm (W)140-350mm | (L)150-500mm (W)250-400mm | (L)20-500mm (W)140-500mm |

| Output | 10-70 BPM | 15-60 BPM | 15-60 BPM | 10-50 BPM | 5-30 BPM | 2-30 BPM |

| Film Width (mm) | 120 ~ 420 | 220 ~ 520 | 220 ~ 620 | 300 ~ 720 | 340 ~ 800 | 300 ~ 1050 |

| Film Thickness (mu) | 30 ~ 100 | 40 ~ 100 | 40 ~ 100 | 50 ~ 120 | 60 ~ 150 | 70 ~ 200 |

| Air Consumption | 0.5m3 per min | 0.4m3 per min | 0.4m3 per min | 0.5m3 per min | 0.7m3 per min | 0.7m3 per min |

| Machine Dimensions (mm) | 1530x970x1600 | 1430x1200x1700 | 1430x1200x1700 | 1340x1580x1950 | 1500x1680x2100 | 1740x2080x2500 |

| Weight (Kg) | 450K | 680 | 700 | 800 | 1000 | 1200 |

| Power | 2.2kW (220V- 50/60Hz) | 2.5kW (220V- 50/60Hz) | 2.5kW (220V- 50/60Hz) | 2.5kW (220V- 50/60Hz) | 3kW (220V- 50/60Hz) | 3kW (220V- 50/60Hz) |

Vertical Form Fill Seal Packaging Machines Selection

Vertical Form Fill Seal Packaging Machines can be categorized into various types based on material type and function. For example, powder packaging machines specialize in powdered materials, granular packaging machines are suitable for granular products, liquid/sauce packaging machines handle fluids, solid-liquid mixed packaging machines accommodate both, and multi-lane packaging machines improve efficiency.

Powder packaging machines are designed for powdered materials, commonly packaging milk powder, seasoning powder, and coffee powder. Due to the poor flowability of powdered materials, they are often equipped with screw metering to ensure accurate metering. The rotating screw delivers powder evenly and quantitatively into the packaging bag, effectively preventing problems such as powder clogging and inaccurate metering.

Particle packaging machines are suitable for granular products such as candy, nuts, and grains. The measuring cup method is simple and direct, enabling quick quantitative packaging. Multi-head combination weighers, with their high-precision sensors and intelligent algorithms, achieve more accurate and efficient particle metering, making them particularly suitable for products requiring high metering accuracy.

Liquid/sauce packaging machines are equipped with liquid or piston pumps to precisely control the flow rate of liquids or sauces. Fluids of varying viscosities, such as beverages, sauces, and detergents, can be stably packaged using the appropriate pump, ensuring a consistent amount of material in each bag.

Solid-liquid mixing packaging machines are commonly used for packaging products such as instant soups and seasoning packets. They precisely mix solid and liquid ingredients in a single batch, meeting consumer demand for convenient foods.

Multi-lane packaging machines can form multiple individual small bags at once, significantly improving production efficiency. Small-dose products like sugar and salt packets can be packaged using this machine, enabling high-volume production in a short time and reducing production costs.

Vertical Form Fill Seal Packaging Machines Operating Principle

The Vertical Form Fill Seal Packaging Machine operates as follows: a roll of packaging film is conveyed via guide rollers to the former, where it is heated and pressed by longitudinal sealing rollers to form a cylindrical bag. Products such as granules, powders, and liquids are then filled into the bag using gravity or mechanical means. Horizontal sealing rollers then heat and pressurize the top of the bag tube, forming the top seal for the current bag and the bottom seal for the next bag. Finally, a cutter separates the sealed bags, completing the fully automated bag-making, filling, and sealing process.

Vertical Form Fill Seal Packaging Machines Applications

The food industry is the largest application area for Vertical Form Fill Seal Packaging Machines, encompassing products such as potato chips, nuts, candy, coffee, frozen foods, and liquid foods, extending their shelf life through nitrogen filling and enhanced sealing technologies. Non-food applications include packaging for daily necessities (such as laundry detergent and cosmetics), pet food, pharmaceutical products (such as tablets and syringes), and industrial supplies (such as screws and textiles).

Vertical Form Fill Seal Packaging Machines Market Price Range Reference

Depending on package weight, material type, and functional configuration, the price range for Vertical Form Fill Seal Packaging Machines varies widely:

Standard models (such as the V320): Primarily suitable for packaging basic granules or powders, with bag widths up to 160mm and a production capacity of 30–50 bags/minute. They are relatively affordable, ranging from approximately $4,000 to $6,000 USD.

Advanced models (such as the V520): These machines accommodate a wider variety of materials and larger bag formats. Equipped with servo drives and intelligent detection capabilities, they improve packaging accuracy and efficiency, priced between $8,000 and $12,000.

High-speed models (such as the V720): These machines feature multi-channel feeding and multi-lane bag-making, supporting in-line operation and boast outputs exceeding 80 bags per minute. Prices range from $15,000 to $25,000, with a complete packaging line costing over $30,000.

Vertical Form Fill Seal Packaging Machines Supplier

Our Vertical Form Fill Seal Packaging Machines are renowned for their modular design, supporting rapid changeovers across multiple bag formats and meeting efficient production needs of 30-300 bags per minute. These machines utilize an intelligent metering system to precisely control the fill volume for materials such as granules, powders, and liquids, with an error rate of less than 0.5%. They also feature an adjustable sealing mechanism that uses temperature and pressure control to ensure seal strength and are compatible with composite film materials such as PE and aluminum foil. Our factory supports non-standard customization in terms of production volume, model, and functionality, and we also offer trial runs with materials. Inquiries are welcome.

Vertical Form Fill Seal Packaging Machines Customer Case Studies

A snack brand introduced a high-speed VFFS packaging machine to address traditional packaging challenges, enabling automated packaging of potato chips and nuts. The machine boasts a speed of up to 120 bags per minute and features nitrogen exchange. Since its launch, production has increased by 40%, resulting in attractive packaging and positive market feedback.

A laundry detergent company customized VFFS equipment, compatible with 200g to 2kg stand-up pouches. Equipped with high-precision weighing and a moisture-proof valve with an accuracy of ±1g, the machine's automatic film change system reduces downtime and increases production efficiency by 35%.

A German company deployed a combination of Vertical Form Fill Seal Packaging Machines and a lane counter to efficiently process frozen pastry packaging on two production lines. The equipment accommodates multiple film roll sizes and offers a compact layout, significantly improving packaging efficiency for a wide range of product categories.

The Industrial Value of Vertical Form Fill Seal Packaging Machines

The industrial value of Vertical Form Fill Seal Packaging Machines lies in their ability to cleverly utilize vertical space, significantly reducing floor space and making them particularly suitable for small and medium-sized enterprises with limited plant space, thereby reducing costs such as site rental. The machine ensures consistent size, weight, and seal height for each bag of product, effectively improving product standardization and making products more competitive in the market. Equipped with a high-quality electronic control system, including a PLC and touch screen, it precisely controls various parameters, reduces failure rates, and facilitates routine maintenance. From 3g seasoning packets to 2kg large packages, it effectively meets the diverse production needs of enterprises.