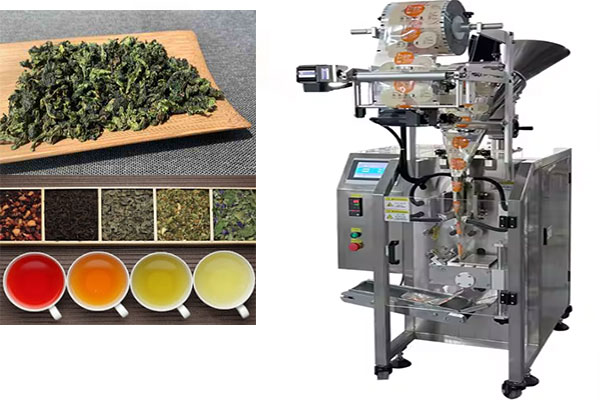

Tea Granule Packaging Machine

Tea Granule Packaging Machines typically pack at speeds between 30 and 80 bags per minute. Basic models range from approximately US$4,000 to US$8,000. Packaging Speed: 30–80 bags/minute Weighing Range: 1–50g/bag Weighing Method: Volumetric or Electronic Weight Bag Dimensions: 50–200mm in length, 40–150mm in width

What is Tea Granule Packaging Machine?

Tea Granule Packaging Machine is designed for automated quantitative filling and packaging of various granular and broken tea leaves. It is suitable for a variety of granular teas, including green tea, oolong tea, flower and fruit tea, instant tea, and some functional teas. Compared to loose leaf tea, granular tea has a more uniform particle size and better flowability, making it easier to measure and package with the machine. Common bag types include three-side seal, four-side seal, back seal, stand-up pouches, zippered stand-up pouches, and triangular tea bags. Bag materials include CPP, PET/PE, AL/PE, and kraft paper/PE composite films, meeting the needs of tea products of varying grades and uses.

Tea Granule Packaging Machines typically pack at speeds between 30 and 80 bags per minute, with high-end models reaching up to 120 bags per minute. Packaging accuracy depends on the metering method and can be adjusted between ±0.1 and 0.5g. Basic models range from approximately US$4,000 to US$8,000. Mid- to high-end models equipped with multi-head weighers and adapted for multiple bagging are priced between US$9,000 and US$13,000, while high-speed, fully automated intelligent models can cost up to US$15,000.

How a Tea Granule Packaging Machine Works

The core components of a Tea Granule Packaging Machine are metering and bag making. Tea granule metering methods are primarily divided into volumetric and gravimetric methods. Volumetric metering typically uses a rotary measuring cup to determine fixed volume. Its advantages are speed and cost-effectiveness, making it suitable for tea with uniform particle density and less demanding metering accuracy. Gravimetric metering, on the other hand, often employs a servo motor-driven screw or multi-head combination weigher. Its advantage is its extremely high accuracy, reaching ±0.1g or even better, making it suitable for high-value, small-format tea packaging, especially for export or high-end markets.

Tea Granule Packaging Machine Packaging Types

The Tea Granule Packaging Machine supports a variety of bag types and packaging styles. Common bag types include three-side seal, four-side seal, back seal, stand-up pouches, zipper bags, bags with hanging holes, and triangular 3D tea bags. Different bag types cater to different market demands and product levels. Cutout shapes can also be flexibly customized, such as right-angle cutouts, rounded corner cutouts, or serrated tear-off notches to enhance the user experience. Metering methods are still divided into volumetric and gravimetric. Volumetric methods are suitable for large-scale production and cost control, while gravimetric methods are used for high-precision packaging. Common packaging films include CPP, PET/PE composites, AL/PE composites, and kraft paper/PE. Regarding film roll specifications, most machines support rolls with an outer diameter of 300–400mm, a core inner diameter of 75mm, and a film width range of 50–320mm (some models can reach over 400mm). The corresponding bag sizes generally range from 50–200mm in length and 40–150mm in width, meeting the requirements for both exquisite packaging of small tea bags and larger products.

Tea Granule Packaging Machine Technical Parameters

| Parameters | Triangular bag model | Inner and outer bag model | Vacuum model | Flat bag model |

| Packing speed | 30-150 bags/minute | 30-100 bags/minute | ≤90 bags/minute | 20-180 bags/minute |

| Measuring range | 1-10 grams | 1-5 grams (inner bag) | 1-1500 grams | 1-10 grams |

| Measuring accuracy | ±0.15 grams | ±0.15 grams | 1/1000F.S.2σ | ±0.2 grams |

| Bag size | Width 40-90mm, length 40-100mm | Inner bag 50-80mm, outer bag 70-100mm | Length 40-100, width 45-75mm | Length 100-500mm |

| Power supply | 220V/50Hz/1.5KW | 220V/3.5KW | 220V50-60Hz/300W | 220V/2.8KW |

| Air source pressure | 5-7Mpa | - | - | ≥0.6Mpa |

| Equipment size | 900×700×1700mm | 900×610×1500mm | 520×630×1750mm | 1250×800×1850mm |

| Equipment weight | 400KG | 500KG | 320KG | 500KG |

| Applicable tea types | Original leaf tea, scented tea | Tea bags | High-grade tea | Various teas |

What types of tea granule packaging machines are there?

Back-seal Tea Granule Packaging Machine (also known as a three-side sealer): This is the most common machine. Three sides (back and two sides) of the bag are heat-sealed, while the front is typically used for printing designs and information. Its relatively simple structure, high speed, and cost-effectiveness make it suitable for a wide range of packaging materials, including tea bags of various specifications, small retail packages, and sample packs.

Four-side seal Tea Granule Packaging Machine: This machine heat-seals all four sides of the bag, allowing for full printing on both the front and back. Its advantages include a more aesthetically pleasing, upscale appearance, a stronger three-dimensional effect, and excellent display quality. It is suitable for products requiring a high-quality packaging, such as gift teas and high-end brand teas.

Stand-up Pouch Tea Granule Packaging Machine: Bags packaged with this stand-up pouch have a folded bottom, allowing them to stand on their own on the shelf. These bags are typically sealed on all four sides or with a back and bottom seal. They offer excellent shelf display, convenient display, and a positive consumer experience. They are suitable for granular teas, blended teas, and gift teas that require upright display.

Zippered Stand-Up Pouch Tea Granule Packaging Machine: This machine incorporates a resealable zipper, based on the stand-up pouch. It offers excellent convenience and preserves freshness. If the product is not fully used, it can be resealed to prevent moisture. It is suitable for larger, reusable tea packages, such as 100g and 250g family packs.

What is the price of a Tea Granule Packaging Machine?

The price of a Tea Granule Packaging Machine varies significantly depending on its configuration and features. Entry-level machines are mostly semi-automatic or single-pouch machines, priced between US$4,000 and US$8,000, making them suitable for small and medium-sized tea companies or start-up brands. Mid-range machines typically feature servo motors, photoelectric tracking, automatic web tracking, and support a variety of bag formats, with prices ranging from US$12,000 to US$25,000. High-end machines often come with multi-head scales, fully automated control systems, and high-speed operation modules, making them suitable for large tea companies or exporters. Prices generally range from US$30,000 to US$50,000. Furthermore, some customized, fully intelligent production lines may require an investment exceeding $60,000. The key price differences lie in packaging speed, metering accuracy, number of compatible bag types, and degree of automation.

Advantages of Tea Granule Packaging Machines

Compared to traditional manual or semi-automatic packaging methods, tea granule packaging machines offer several advantages. First, they are highly automated, enabling an integrated process including automatic loading, metering, filling, bagging, sealing, batch number printing, and finished product output, significantly reducing manual labor. Second, the equipment is primarily constructed of food-grade stainless steel, with precision manufacturing processes ensuring hygiene, safety, and durability. Third, the machine's compact design and small footprint make it suitable for various production workshops. Its user-friendly interface, simple touchscreen operation, and intuitive parameter settings make it easy for ordinary workers to operate after a short training period. Furthermore, modern packaging machines generally feature self-diagnosis and low-material alarms, significantly improving production stability and safety.

Applications of Tea Granule Packaging Machines

Tea Granule Packaging Machines are widely used in the production and packaging of granular teas, including green tea, black tea, oolong tea, flower and fruit tea, and tea bags. It not only serves tea processing factories and export trading companies, but is also adopted by numerous small and medium-sized tea companies and e-commerce brands. With growing consumer demand for portable, small-packaged tea, this equipment has played a key role in the supply of tea products to supermarkets, convenience stores, and e-commerce channels. Especially in niche areas such as functional health tea, blended fruit tea, and instant tea, the Tea Granule Packaging Machine can quickly adapt to different packaging formats and specifications, meeting the diverse and high-standard demands of the market. It has become a key piece of equipment for achieving automated production and enhancing brand competitiveness in the modern tea industry.