Pouch Packing Machine

Pouch Packing Machine can be customized according to bag design, width and packaging capacity, The selection depends on the specific model, the output range is 10 to 120 bags per minute, and the price range is about 8,000 to 50,000 US dollars.

Packaging speed: 10-120 bags/min

Applicable bag type: compatible with various bag types

Measuring range: 10g-5000g

Power specification: AC 220V / 50Hz

Drive mode: servo motor control

What is Pouch Packing Machine?

Pouch Packing Machine can be customized according to bag design, width and packaging capacity, supports personalized pattern printing and quick sealing, and is suitable for a variety of materials such as powders, granules, and liquids. The selection depends on the specific model, the output range is 10 to 120 bags per minute, and the price range is about US$8,000 to US$50,000, meeting the diverse needs from small batch trial production to large-scale automated production.

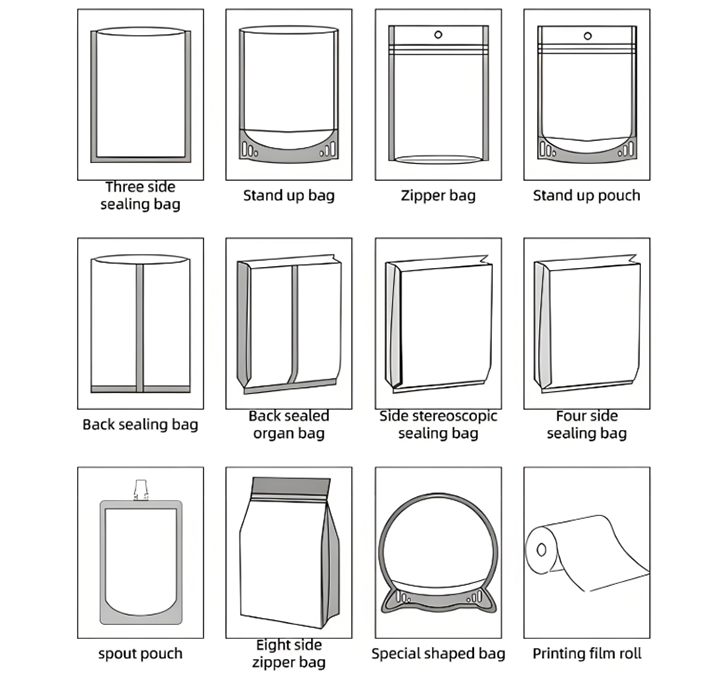

The workflow of Pouch Packing Machine includes automatic feeding, film bag making, metering filling, heat sealing, coding slitting and finished product output. The material enters through the conveying system, the film is sealed after forming and filling, and the label is printed and slid, and the finished product is finally automatically output. Common packaging bag types of Pouch Packing Machine mainly include: three-side sealed bags, back-sealed bags, four-side sealed bags, self-supporting bags, zipper bags, corner bags and special-shaped bags, etc., to meet the packaging of different materials.

Technical parameters of Pouch Packing Machine

| Sealing Type | 3 side sealing or back sealing | Back sealing |

| Packing Weighting Range | 0-20g,0-50g,0-100g | 0-100g,0-200g,50-1000g,100-2000g |

| Power | 550W | 1300W |

| Voltage | 220v,50Hz or 110V,60Hz | |

| Bag Width | 3-15cm | 10-20cm |

| Bag length | 1-15cm (adjustable) | 0-28cm or 0-39cm (adjustable) |

| Packing speed | 30-50 bags/min (Different material packaging weight at different speeds) | |

| Machine Weight | 60g | 90g |

| Machine size | 42*50*145CM | 90*66*180CM |

How to Choose Pouch Packing Machine Equipment Type?

There are two common types of pouch packing machines: vertical form-fill-seal machines and pre-made pouch machines. These two models differ in their applicable materials and appearance. Below is a comparison of the two, allowing users to choose the right model based on their specific needs.

Vertical machines feature an integrated design that automates the bag-making, filling, and sealing processes, eliminating the need for pre-made bags and saving packaging material costs. They are suitable for a variety of materials, including granules, powders, and liquids, and have a compact footprint, making them suitable for small to medium-sized batch production. However, they have certain limitations in material compatibility and are susceptible to material flow during high-speed operation.

Pre-made pouch machines require pre-made bags and offer strong compatibility with various bag shapes. They can handle complex bag shapes, such as stand-up pouches and zipper bags, and offer high sealing precision and excellent airtightness, making them suitable for high-value-added products. They are suitable for liquids, sauces, and bulk materials, offering high stability and suitability for large-scale continuous production. These machines require a larger footprint than vertical machines.

What are the main features of Pouch Packing Machine?

Pouch Packing Machine is equipped with a touch screen, small size, easy to install, supports multiple measurement methods and packaging bag types such as weight and volume, stable sealing, maintains the characteristics of the material, and improves efficiency and reliability.

Advanced human-machine interface: equipped with a touch screen operation interface, which is convenient for quick parameter setting, real-time monitoring of operating status, and has automatic fault diagnosis function to improve operating efficiency and reliability.

Compact structure design: The equipment is small in size, occupies a small area, adapts to the space layout of various production workshops, and is easy to install and maintain.

Diverse measurement methods: supports multiple forms such as weight measurement and volume measurement to ensure accurate packaging of different product types and improve measurement accuracy.

Diversified packaging: This machine can be adapted to pre-made bags or roll film bags, including zipper self-supporting bags, liquid bags with nozzles, special-shaped custom bags, etc., and can be flexibly switched by quickly changing molds.

Stable sealing performance: The sealing is firm and uniform, which can effectively maintain the sealing of the packaging bag, prevent the product from being damp, oxidized or leaking, and ensure the quality of the material.

Pouch Packing Machine Packaging Bag Types

Pouch Packing Machine can adapt to the mainstream bag types in the market to meet the diversified packaging needs of different industries. The equipment can achieve precise forming, filling and sealing according to the bag type, improve packaging efficiency and bag type compatibility, and is suitable for production needs at different production stages.

Three-side sealed bags: heat-sealed on both sides and the top, folded on the back, fast packaging speed (40-60 bags/minute), suitable for PE, CPP and other films, capacity range 50-1000ml, commonly used in small packages such as snacks and medicines.

Back-sealed bags: middle seam back seal, flat front, suitable for label printing, medium packaging speed (30-50 bags/minute), mostly PET/PE composite materials, capacity 100-2000ml, such as medium-sized packaging such as seasonings.

Four-side sealed bag: four-sided sealed, strong three-dimensional sense, slow packaging speed (20-40 bags/minute), suitable for aluminum-plastic composite film or galvanized film, capacity 50-500ml, used for high-end food or electronic products and other delicate packaging.

Stand-up bag: bottom support can stand upright, medium-high packaging speed (40-70 bags/minute), suitable for composite materials such as PET/AL/PE, capacity 200-5000ml, such as liquids, sauces and other medium and large packaging.

Zipper bag: bag mouth with resealable zipper, medium packaging speed (30-50 bags/minute), suitable for PE, CPP and composite film, capacity 100-2000ml, used for daily packaging of ready-to-eat food, dry goods, etc.

Gusseted bag: bottom gusset design increases capacity, medium packaging speed (25-45 bags/minute), suitable for PP, PE and other materials, capacity 500-5000ml, suitable for large-volume products such as pet food and other large-volume packaging.

Special-shaped bags: customized shapes (such as mouths and handles), low packaging speed (10-30 bags/minute), suitable for a variety of composite films, capacity 50-1000ml, mostly used for creative packaging or special packaging such as gift industry.

Pouch Packing Machine Case

Pouch Packing Machine realizes packaging and nitrogen preservation in the food industry, liquid filling and special-shaped bag packaging with an error of ±0.5% in the daily chemical industry, sterile granular drug packaging that meets GMP standards in the pharmaceutical field, pet food uses 200℃ adjustable temperature four-side sealing to ensure safety, and industrial applications have achieved a breakthrough in leak-proof filling of viscosity lubricating oil.

Food industry: A leisure food company uses a fully automatic vertical Pouch Packing Machine to pack nuts, equipped with a dual-channel weighing system with an accuracy of ±0.3g, and a nitrogen replacement device to extend the shelf life by 30%.

Daily chemical industry: A brand of shampoo introduces a servo-driven liquid filling machine with an integrated visual inspection system to achieve 1-500ml accurate filling with an error of ±0.5%, and supports a variety of packaging forms such as self-supporting bags and special-shaped bags.

Pharmaceutical industry: A pharmaceutical company uses an aseptic Pouch Packing Machine to pack granular medicines, using aluminum-plastic composite film heat sealing, with a sealing strength of 50N/15mm, which meets the requirements of GMP clean workshops.

Pet food: The packaging of freeze-dried cat food adopts a four-side sealing design, with an adjustable sealing temperature of 200℃, and a metal detector to ensure that each bag of product is free of impurities.

Industrial field: The lubricating oil packaging machine is equipped with an anti-drip nozzle and a viscosity compensation system, which is suitable for liquids of different viscosities from 5-5000cSt, and a filling speed of 40 bags/minute.

Pouch Packing Machine Solution

Pouch Packing Machine is suitable for a variety of material types, including powders (such as milk powder, seasonings), granules (such as nuts, candies), liquids (such as sauces, beverages) and pastes (such as cosmetics, medicines). For materials with different characteristics, it is necessary to select suitable metering and filling systems, such as screw metering for powders and liquid pumps for fluids.

Production selection suggestions:

Small batch production (<1000 bags/hour): Choose semi-automatic or desktop models, which are flexible and economical, suitable for start-ups or trial production.

Medium batch production (1000-5000 bags/hour): Fully automatic vertical packaging machine, balancing efficiency and cost, suitable for medium-sized production lines.

Large batch production (>5000 bags/hour): High-speed rotary or multi-station models, integrated weighing and sealing systems, to meet the needs of continuous industry.

Key points for selecting Pouch Packing Machine

To select a suitable Pouch Packing Machine, it is necessary to comprehensively consider multiple key factors such as production requirements, packaging bag types and materials, product characteristics, price budget, equipment maintenance and after-sales service, as well as scalability and intelligence. Through reasonable evaluation of factors, enterprises can purchase Pouch Packing Machines that are cost-effective and suitable for their own production needs, and realize packaging automation and maximize production benefits.

Production requirements: Determine the packaging speed according to the production scale. The larger the output, the higher the need to choose a high-speed, highly automated model to meet the demand of 10 to 120 bags per minute.

Product features: Different product forms (granules, powders, liquids) have different requirements for metering and packaging methods. When selecting a model, you need to match the corresponding metering system and filling device.

Price budget: The price range is large, ranging from $8,000 for an economical model to $50,000 for a fully functional model. When the budget is sufficient, it is recommended to choose a model with complete functions, high automation, and convenient maintenance.

Equipment maintenance and after-sales service: Prioritize brands that are easy to maintain and have sufficient spare parts supply to ensure long-term stable operation and timely technical support.