Horizontal Packaging Machine

Horizontal Packaging Machine is between $1,000 and $30,000. It is an automated equipment designed for packaging sheet, block, and regular materials. The packaging speed is usually between 30-300 packs/minute, which can be adjusted according to different products and packaging films. Maximum packaging speed: 120 packs per minute Packaging width: adjustable 150-350mm Power requirement: AC 220V 50Hz Packaging material: film bags, paper bags can be used Applicable products: food, medicine, daily necessities Control system: PLC + touch screen operation Dimensions: length 3500mm × width 1200mm × height 1600mm

Horizontal packaging machine is an automated equipment designed for packaging sheet, block, and regular materials. For example, candies, biscuits, wet wipes, masks, soaps, blades, small tools, etc. can all be packaged at high speed by horizontal packaging machines. Its working principle is to convey the product to the former through horizontal feeding, and the film is folded into a bag shape in the forming device. At the same time, filling, heat sealing, cross-cutting and other actions are completed during the product passing process, and finally a complete packaged product is formed. The whole process is automatically managed by the PLC control system, and the operation is stable and the rhythm is smooth. The packaging speed is usually between 30-300 packs/minute, which can be adjusted according to different products and packaging films; the packaging size range is flexible, suitable for products of different lengths and heights; the power is about 3-6kW; the footprint is small, which is convenient for integrated use on the assembly line. The equipment has a variety of intelligent functions such as automatic film supply, automatic film calibration, material shortage shutdown, servo drive, etc., which can greatly improve packaging efficiency and finished product consistency.

Advantages of Horizontal Packaging Machine

Horizontal Packaging Machine has high packaging efficiency, wide application range, beautiful and stable finished products, etc., and is widely used in various automatic packaging production lines for regular or fragile products.

First of all, the equipment adopts a continuous operation mode, which is suitable for high-speed production line operation, significantly improves the packaging speed and overall production efficiency, and meets the production needs of large quantities and high rhythm.

Secondly, it has a wide range of applications, especially for solid objects with regular shapes, materials with trays, etc. The equipment is accurately positioned during the packaging process to ensure packaging consistency, which helps to improve the overall packaging quality.

In addition, the finished product packaging has a neat and beautiful appearance, a fixed sealing position, and a regular bag shape, which is not only convenient for subsequent stacking and transportation, but also enhances the added value and market competitiveness of the product.

Compared with vertical packaging machines, Horizontal Packaging Machine has more outstanding advantages when processing regular or fragile products. Its transmission process is smooth, effectively avoiding damage or dislocation caused by falling, improving packaging accuracy and finished product consistency, especially suitable for non-fluid products such as biscuits and facial masks. Vertical packaging machines are more suitable for free-flowing materials such as granules, powders, and liquids, and their adaptability is relatively low.

Technical specifications of Horizontal Packaging Machine

Horizontal Packaging Machine has high-speed and high-precision packaging capabilities, supports multi-specification customization, adopts PLC control and servo drive, and the structure is made of 304 stainless steel. Specific technical specifications are as follows:

Packing speed: 30-300 bags/minute (depending on product form and bag type)

Packaging size: 80-400mm in length, 30-200mm in width, 5-80mm in height (customizable)

Power requirements: AC220V/380V, 50/60Hz

Power consumption: about 3-6kW

Control system: PLC+touch screen, supports Chinese and English interface switching

Drive mode: servo motor drive, precise position

Material structure: 304 stainless steel for the whole machine, in line with food and pharmaceutical industry standards

Packing style of Horizontal Packaging Machine

Horizontal Packaging Machine supports a variety of packaging forms, including pillow bags, gusset bags, four-side sealed bags, joint bags, packaging with easy-tear edges, etc.:

Pillow bags are the most common packaging form, with simple structure and high efficiency, suitable for most regular products, such as biscuits, facial masks, medicines, etc. Its packaging appearance is neat and low cost, making it an ideal choice for standardized production.

The gusseted bag has a foldable structure on both sides of the bag body to enhance the three-dimensional sense and carrying capacity of the package. It is especially suitable for products of larger size or that need to be stacked and stored, such as large packaged food, daily necessities, etc., with excellent visual effects and display effects.

The four-side sealed bag adopts a four-side sealing design, with a more regular overall shape and tight sealing, which can effectively improve the sealing and protective performance of the package. It is often used in cosmetics, high-end medical supplies and other products with high requirements for appearance and quality.

The multi-pack bag connects multiple small packages into a row or a group, which is convenient for promotional display and combined sales. It is suitable for combined products, gift packaging or supermarket promotions to enhance product attractiveness and purchase convenience.

The packaging with an easy-tear opening improves the consumer's experience by designing a convenient opening structure, such as an easy-tear opening or a notch line. It is widely used in consumer goods such as snacks and disposable products that require high convenience.

Functions of Horizontal Packaging Machine

Horizontal Packaging Machine not only realizes the basic sealing packaging function, but also expands the following functions according to product and industry needs:

Protection: through airtight packaging or nitrogen filling device, it can effectively extend the shelf life of food and medicine;

Portability: equipped with easy-tear and hanging hole design, making the product more convenient to use;

Automatic identification function: it can be connected to the visual system or sensor to identify the material position and realize accurate packaging;

Batch identification: supports inkjet and coding functions to meet traceability management and product tracking;

Strong connection ability: easy to integrate with automatic feeding system, checkweigher, packing machine and other equipment to realize full-line automatic production.

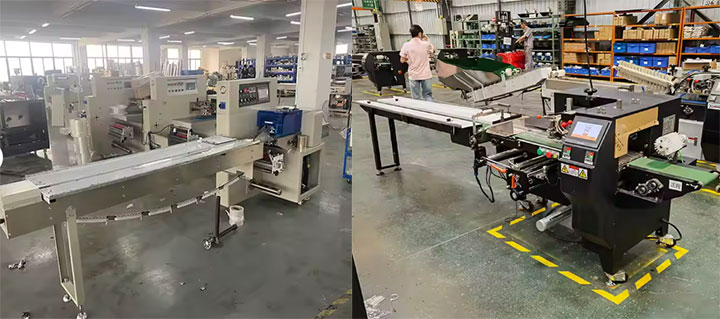

Horizontal packaging machine supplier

Horizontal packaging machine is used in food, medicine, daily chemicals and industrial parts, and can complete the whole process of bag making, metering, filling, sealing and other automatic packaging. The world's major producing countries include China, Germany, Italy, Japan and the United States. Our factory has customization advantages in the field of packaging machinery. Its linear vibrating screen and packaging line linkage solution can achieve 20 tons of material screening and packaging coordination per hour, support customization of multiple specifications from 520 to 1500, and is equipped with intelligent functions such as fault self-diagnosis and temperature PID control to meet the requirements of food-grade 304 stainless steel.

Horizontal Packaging Machine has become an ideal choice for many companies to achieve automated packaging upgrades with its high efficiency, high precision and diversified functions. It is especially suitable for product lines that require regular placement, high-aesthetic packaging and various bag types. Compared with vertical packaging machines, it has obvious advantages in packaging accuracy, appearance beauty, equipment adaptability and other aspects. The horizontal packaging machine produced by our factory has a compact structure and advanced configuration. It can be customized according to different products to help companies improve production line efficiency and product competitiveness.