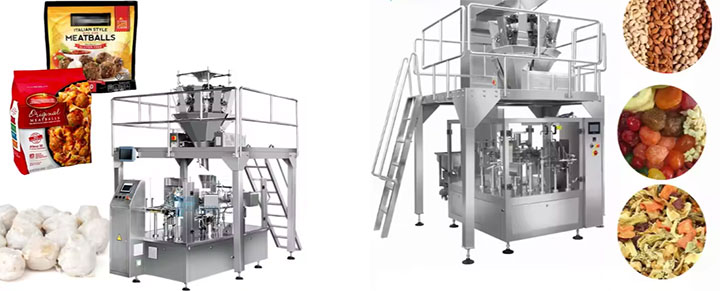

Granules Packaging Machine

Granules Packaging Machine packaging speeds vary by machine model: standard vertical machines can reach 30-80 bags/minute , multi-head weighing machines can exceed 130 bags/minute, and ton bag packaging machines consistently deliver 50-160 bags/hour. Granules Packaging Machine basic models priced between $3,000 and $5,000, while the mid-range to high-end multi-head Granules Packaging Machine ranges from $10,000 to $20,000. Packaging Weight: 20g-2kg Packaging Speed: ≥30 bags/minute Bag Types Supported: Back Seal, Three-Side Seal, Four-Side Seal Material: Polyester/Polyethylene and other composite film materials Control System: PLC + HMI

What is Granules Packaging Machine?

Granules Packaging Machine performs the packaging process for granules, including dosing, weighing, filling, and sealing. The packaging range generally ranges from 5g to 5kg, and it supports a variety of bag types, including three-side seal, four-side seal, back seal, and stand-up pouches. It is suitable for a wide range of materials, including candy, nuts, dried fruit, roasted seeds and nuts, rice, grains, coffee beans, seeds, seasonings, chemical granules, and pet food. Packaging speeds vary by machine model: standard vertical machines can reach 30-80 bags/minute (depending on the machine model and material characteristics), multi-head weighing machines can exceed 130 bags/minute, and ton bag packaging machines consistently deliver 50-160 bags/hour. The Granules Packaging Machine offers a range of pricing, with basic models priced between $3,000 and $5,000, while the mid-range to high-end multi-head Granules Packaging Machine ranges from $10,000 to $20,000.

Advantages of the Granules Packaging Machine

The Granules Packaging Machine offers numerous advantages. Its modular design makes it compact and takes up little space, making it easy to install and maintain. Key components are constructed of stainless steel or wear-resistant materials, making them corrosion-resistant and meeting food and pharmaceutical hygiene standards. Parameters can be easily adjusted via a touchscreen. Functionally, the machine boasts high-precision metering capabilities, suitable for a variety of materials, including granules and powders, with an accuracy control within ±1%. Its high degree of automation integrates automatic bag making, filling, sealing, and coding, significantly improving production efficiency. It supports a variety of packaging styles (such as back-seal, three-side seal) and materials (composite film, aluminum foil, etc.). Furthermore, its flexible packaging capacity range, from 5g to 5kg, can be customized to meet specific needs. Its variable-speed motor control enables packaging speeds exceeding 60 bags per minute, making it ideal for high-volume production.

Granule Packaging Machine Specifications

| Model(Roll film width) | FP-320 | FP-420 | FP-540 | FP-730 | FP-920 | FP-1100 | FP-1500 |

| Bag Length(mm) | 80-180 | 80-300 | 80-400 | 100-400 | 150~600 | 200~900 | 200-1000 |

| Bag Width(mm) | 45-150 | 50-200 | 80-250 | 180-350 | 150~450 | 150~530 | 200~730 |

| Max Width of Roll(mm) | 320 | 420 | 520 | 720 | 920 | 1100 | 1500 |

| Packing Speed(bags/min) | 20-55 | 20-80 | 20-100 | 20-100 | 10~90 | 10-80 | 5-50 |

| Air Consumption(Mpa) | 0.65 | 0.65 | 0.65 | 0.65 | 0.65 | 0.65 | 0.65 |

| Gas Consumption(m3/min) | 0.3 | 0.3 | 0.4 | 0.4 | 0.5 | 0.5 | 0.5 |

| Power Voltage (v) | 220v/380v | 220V/380v | 220v/380v | 220v/380v | 220v/380v | 220v/380v | 220v/380v |

| Power (kw) | 3kw | 2.2KW | 4kw | 5kw | 5kw | 6kw | 6kw |

| Weight(kg) | 350 | 540 | 600 | 900 | 1000 | 1100 | 1200 |

What types of Granule Packaging Machines are there?

Granule Packaging Machines are categorized by function into four types: vertical, automatic, multi-head weighing, and multi-function. These machines are suitable for different production capacities and packaging requirements, with prices ranging from $3,000 to $20,000. They serve a wide range of applications from small and medium-sized enterprises to large manufacturers.

Vertical Granule Packaging Machines: These machines have a simple structure, primarily consisting of a machine frame, a volumetric cup, a bag-making device, and a sealing system. They are easy to operate and are suitable for packaging small and medium-sized granular materials. They are typically equipped with a volumetric cup for measuring. Prices range from approximately $3,000 to $6,000, making them suitable for small and medium-sized enterprises or startups.

Automatic Granule Packaging Machines: These machines include an automatic weighing system, a material unloading mechanism, a film-winding device, and a PLC control system. They automatically weigh, fill, and seal, saving labor and are suitable for medium-to-high-speed packaging of most granular materials. Prices range from $5,000 to $8,000, depending on configurations (such as whether they have a touchscreen).

Multi-Head Granules Packaging Machine: Consisting of multiple electronic weighing heads, a collection hopper, a control system, and a high-efficiency packaging unit, it offers high weighing accuracy and speed, making it suitable for packaging high-end foods, snack foods, nuts, and other products. Its price is relatively high, typically ranging from $9,000 to $15,000, making it suitable for medium- to large-scale manufacturers.

Multi-Function Granules Packaging Machine: Its structure integrates powder, liquid, and granule packaging modules, offering powerful functionality and enabling the alternating packaging of multiple materials, reducing the need for equipment changeovers. Priced between $10,000 and $20,000, it is suitable for companies with more complex product lines.

What is the Granules Packaging Machine workflow?

The Granules Packaging Machine workflow is: feeding - metering - bagging - filling - sealing - and discharging. Starting with feeding, granules are fed into the hopper via a vibrating feeder or screw conveyor, ensuring continuous and stable feeding. Subsequently, the granules enter the metering stage, where a volumetric or gravimetric metering device (such as a screw meter, measuring cup, or electronic scale) accurately distributes the weight of each bag. Next comes the bag-making stage, where the packaging film is rolled into a tube by a former. A longitudinal sealing device heat-seals the sides to form an open bag. The measured granules drop into the bag through the discharge port, and a photoelectric sensor controls the filling position. After filling, a transverse sealing device heat-seals the bag opening and cuts it, simultaneously forming the bottom of the next bag. The finished bag is then discharged by a conveyor belt and can be connected to a printer to print the date or batch number.

Common Applications of Granule Packaging Machines

Granules Packaging Machines are used in industries such as food, pharmaceuticals, chemicals, building materials, and agriculture. Common packaging materials include candy, nuts, biscuits, seeds, laundry detergent, feed, and granular pharmaceuticals. In the food industry, granule packaging machines are commonly used for quantitative packaging of condiments and snacks; in the pharmaceutical industry, they are primarily used for the precise packaging of granules and traditional Chinese medicine granules; in the chemical industry, they are used for quantitative filling of chemical products such as fertilizer granules, plastic raw materials, pigments, and dyes; and in the building materials industry, they are used for moisture-proof packaging of granular building materials such as cement additives, gypsum, and sand. In the agricultural sector, granule packaging machines are primarily used for quantitative packaging of granular agricultural products such as corn seeds, wheat seeds, and rice seeds.

Granules Packaging Machine Packaging Solutions

Granules Packaging Machines offer a variety of packaging solutions, with flexible parameter adjustments tailored to meet specific needs.

Food Industry: For small granules such as candy and nuts, vertical packaging machines with multi-row parallel technology are used to achieve high-speed production of over 600 bags per hour. For example, one factory's production line uses a bag-in-bag weighing machine to ensure a weight error of ≤0.5% per bag.

Chemical Industry: For fertilizers and plastic granules, ton bag packaging machines with integrated vibratory feeding and heat sealing systems are used. Each bag has a capacity of 500-1000kg and features a dust-proof design to meet the high-volume packaging needs of enterprises.

Pharmaceutical Industry: For the packaging of traditional Chinese medicine granules, precision metering devices are used. A vertical drive assembly quickly adjusts the measuring cup volume, achieving high-precision packaging of 5g per bag with a failure rate of less than 0.3 times per thousand hours.

Building Materials Industry: Moisture-proof packaging for cement additives and other products uses vacuum shaping technology combined with composite film materials to extend the shelf life of the materials to over 12 months.

Granules Packaging Machine Main Components

Granules Packaging Machine primarily consists of an automatic weighing system, a feeding device, a former, a heat-sealing system, a bag cutting device, and a control system. The automatic weighing system ensures packaging accuracy. The feeding device evenly delivers granular materials into the packaging area. The former folds the packaging film into bags. The heat-sealing system seals the bags. The bag cutting device cuts the bags on demand. The control system provides automated operation and monitoring of the entire machine.

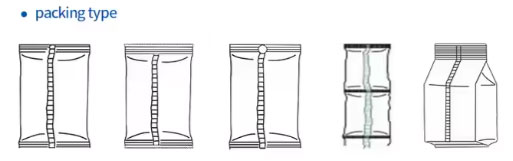

Granules Packaging Machine Bag Types

A variety of bag types are available for the Granules Packaging Machine, including but not limited to back-seal bags (center-seal bags), three-side-seal bags, four-side-seal bags, and stand-up pouches. Stand-up pouches are suitable for high-end retail products, while back-seal bags are the most common and economical packaging method.

Back-seal bags: The bags are sealed on the back, offering strong sealing and excellent moisture-proofing. Common bag materials include plastic films such as polyethylene (PE) and polypropylene (PP). These materials are flexible and low-cost, making them suitable for packaging granular materials such as seeds and feed, effectively protecting them from moisture and contamination.

Three-side-seal bags: Sealed on three sides, with the opening at the top, provide convenient access to the product. Composite films such as PET/PE, BOPP/CPP are often used. These composite films offer excellent barrier, printability, and mechanical properties, making them suitable for packaging small-grain foods such as candy and nuts, facilitating shelf display.

Four-side-seal bags: Sealed on all four sides, they offer a stable structure but require extremely high sealing properties. Aluminum-plastic composite film is often used, as the aluminum layer effectively blocks light, oxygen, and moisture. These bags are commonly used for packaging products requiring a high degree of sealing, such as pharmaceutical granules and chemical reagents.

Pillow bags: Full, pillow-like, and aesthetically pleasing. Typically, composite materials such as polyester (PET), aluminum foil (AL), and polyethylene (PE) are used. This combination ensures packaging strength while effectively preventing spoilage, making it suitable for packaging large-grained items such as potato chips and puffed foods.

Stand-up pouches feature a support structure at the bottom, allowing them to stand upright for outstanding display on supermarket shelves. These pouches are often made of multi-layer composite films, such as NY/PE or PET/NY/PE. They offer excellent stiffness, barrier properties, and puncture resistance, making them suitable for packaging products such as pet food and snacks.