Fully automatic weighing packaging machine

Fully automatic weighing packaging machine Common models include WPM-500 (for 50g–500g), WPM-1000 (200g–1kg), WPM-5000 (1–5kg), etc., with an output range from 20 bags to 60 bags per minute. Prices vary depending on model and configuration, but are generally between USD $4,000–$15,000. Packaging speed: 20-80 bags/minute Bag width range: 80-250mm Bag length range: 100-400mm Power supply specification: AC220V/50Hz Power demand: about 3.5kW Air source pressure: 0.6MPa Applicable materials: granules, powders

What is Fully automatic weighing packaging machine?

Fully automatic weighing packaging machine is a comprehensive packaging equipment that integrates automatic metering, filling, bag making, sealing, coding, and bag cutting. Through the preset program, the equipment can accurately complete the weighing and high-speed packaging of materials, and is widely used for materials such as granules, powders, flakes, blocks, such as rice, seeds, feed, washing powder, candy, seasonings, fertilizers, plastic granules, etc. The equipment consists of a material conveying system, a weighing system, a packaging host, a control system, and a finished product output system. It runs stably and is intelligently operated. Common models include WPM-500 (for 50g–500g), WPM-1000 (200g–1kg), WPM-5000 (1–5kg), etc., with a production range of 20 bags to 60 bags per minute. The price varies depending on the model and configuration, generally between USD $4,000–$15,000, and is suitable for the automated packaging upgrade needs of small and medium-sized enterprises to large production lines.

Working principle of Fully automatic weighing packaging machine

The core of Fully automatic weighing packaging machine lies in the deep integration of dynamic weighing and automated packaging. The workflow starts with the weighing system. The material enters the weighing hopper through the conveying equipment. The imported sensor measures the weight in real time and transmits the data to the PLC system. When approaching the preset weight, the system feeds slowly to reduce the error, with an accuracy of ±0.2%. After weighing, the material falls into the packaging container and then seals (supports hot, cold, and ultrasonic sealing). Finished products are output through the conveyor belt, and after metal detection and weight re-inspection, unqualified products are automatically rejected.

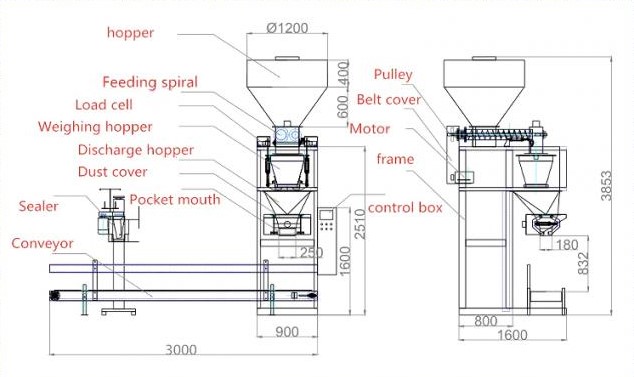

Structure of Fully automatic weighing packaging machine

Fully automatic weighing packaging machine adopts modular architecture, which consists of feeding unit, weighing unit, packaging execution unit, control system, auxiliary module and other components.

The feeding unit is composed of a screw conveyor or vibrating feeder driven by a servo motor, which can be frequency-controlled; for example, the automatic weighing packaging machine for powders adopts a double-screw feeding mode. The weighing unit is based on a high-precision weighing sensor and a dynamic compensation algorithm module, and some models have multi-head combination weighers. The packaging execution unit integrates a variety of devices, such as the pneumatic bag clamp of the fully automatic bagging packaging machine, which can adapt to the bag opening. The control system adopts Mitsubishi or Siemens controller and supports multiple languages. Auxiliary modules include dust removal, visual inspection and data acquisition terminals.

Advantages of Fully automatic weighing packaging machine

The efficiency advantage of Fully automatic weighing packaging machine is significant. Taking hourly production capacity as an example, a single device can complete 300-1200 bags of packaging, which is 3-5 times higher than that of semi-automatic models. In the chemical industry, after a company introduced a fully automatic ton bag packaging machine, the daily production capacity of a single line increased from 20 tons to 80 tons, and the labor cost was reduced by 75%. Cost optimization is reflected in three aspects:

Direct cost savings: The equipment supports 24-hour continuous operation and reduces manual intervention. For example, food companies save 2-3 operators on each production line through the automatic bagging function, saving more than 500,000 yuan in labor costs annually.

Reduced quality costs: The high-precision weighing system controls the product overweight rate within 0.5% to avoid waste of raw materials.

Implicit benefit improvement: The equipment integrates data traceability function, which can record the packaging time, weight, operator and other information of each batch, providing a basis for quality control. In addition, the modular design facilitates rapid changeover. A hardware company replaces the feeding components to achieve mixed loading of screws and gaskets, and the equipment utilization rate is increased by 40%.

Parameters of Fully automatic weighing packaging machine

Fully automatic weighing packaging machine supports packaging in the range of 5kg-50kg, adopts PLC touch intelligent control, with an accuracy of ±0.2%, suitable for a variety of bag widths and material selections, and runs stably and quickly. The specific parameters are as follows:

| Metering Mode | Auger filling, Loading cell |

| Package Weight | 5kg / 10kg / 15kg / 20kg / 25kg / 50kg or customized |

| Materials | SS304 / SS316L / Carbon steel |

| Package Accuracy | ±0.2-1%(according to the material) |

| Packaging Speed | 2-10bags/min(according to the material) |

| Power Supply | 220V,380V,480V or customized |

| Hopper Volume | 50L |

| Total Power | 5Kw |

| Overall Dimensions | 1000×900×2150mm or customized |

| Operational Style | PLC control system,Colorful touch screen |

Model types of Fully automatic weighing packaging machine

There are many models of Fully automatic weighing packaging machine, which are usually named and classified according to the weighing range, packaging speed, material type and bag structure. The following are several common models and their applicable situations:

Classification by weighing range (based on the weight of each bag):

| Model Name | Weighing Range | Suitable Materials |

| WPM-500 | 50g - 500g | Small-package granules, powders |

| WPM-1000 | 200g - 1kg | Rice, sugar, beans, seasonings, etc. |

| WPM-2000 | 500g - 2kg | Fertilizers, feeds, granules, etc. |

| WPM-5000 | 1kg - 5kg | Chemical granules, agricultural products, etc. |

| WPM-10K | 5kg - 10kg | Large-package granules, seeds, etc. |

Classification by packaging speed and process configuration:

| Model Name | Packaging Speed | Features |

| WPM-2H | 20 - 30 bags/minute | Single-head weighing, economical type |

| WPM-4H | 40 - 60 bags/minute | Double-head weighing, higher output |

| WPM-6L | 60 - 90 bags/minute | Multi-head linear weighing, higher efficiency |

| WPM-MC10 | 10-head combination | Suitable for mixed packaging of various materials |

| WPM-Rotary | Rotary packaging | High-speed rotation, continuous packaging |

Differentiation by material form and industry application:

| Model | Suitable Materials | Feature Description |

| WPM-GR | Granular (such as sugar, beans) | Double vibration feeding, uniform granules |

| WPM-PW | Powder type (such as milk powder, flour) | Screw metering + sealing and dust removal |

| WPM-LQ | Liquid type (such as sauce, oil) | Equipped with filling pump, leak-proof sealing |

| WPM-FD | Hygroscopic (such as fertilizer) | Waterproof sealing design, stable weighing |

| WPM-MIX | Mixed materials | Multiple metering heads work in coordination, high precision |

Classification by bag type and packaging structure:

| Model | Packaging Bag Type | Features |

| WPM-VFFS | Pillow bags, gusseted bags, etc. | Used with vertical form-fill-seal machines |

| WPM-Pouch | Self-standing zipper bags, pre-made bags | Suitable for high-end packaging, easy to open |

| WPM-Quad | Four-side-sealed square bottom bags | Attractive appearance, good display effect |

| WPM-Gusset | Gusseted bags | Large capacity, suitable for heavy-item packaging |

Price range of Fully automatic weighing packaging machine

The price of Fully automatic weighing packaging machine varies depending on the model, function configuration, material and customization requirements. The following are common price ranges:

WPM-500 weighs 50g-500g, which is a good choice for small packaged food, seasonings, etc. The reference price is between $3,300 and $5,500.

WPM-1000 weighs 200g-1kg, which can meet the weighing needs of rice, sugar, chemical granules, etc., and the price is between $5,000 and $7,200.

WPM-2000 weighs 500g-2kg, suitable for feed, fertilizer, tea, etc., and the price is between $6,000 and $8,500.

WPM-5000 weighs 1kg-5kg, and is composed of a strong weighing component, an intelligent control system, a large hopper and other structures. It can be used for packaging rice, fertilizers, etc., and the price is $7,000-11,000.

WPM-10K (heavy duty) weighs 5kg-10kg, suitable for materials such as plastic particles, and the price is $9,000-15,000.

Multi-head combination weighing scale can handle a variety of mixed materials. It consists of multiple independent weighing units, material distribution system, and integrated control module. The price is around 12,000-20,000 US dollars.

What are the main functions of the fully automatic weighing packaging machine?

The fully automatic weighing packaging machine has core functions such as high-precision weighing, intelligent control, compatibility with various bag types, and strong material adaptability:

Accurate weighing: The equipment is equipped with a high-precision electronic weighing module, which can ensure the stability and consistency of the weight of each bag of material during high-speed operation, and the error can be controlled within ±0.2%.

Intelligent control system: It adopts PLC control and human-machine interface operation, supports real-time data monitoring, automatic fault alarm, self-diagnosis, parameter memory and other functions to improve the convenience and safety of operation.

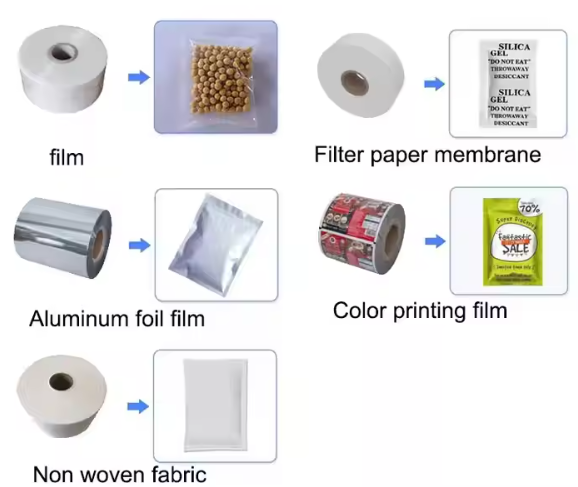

Diversified packaging forms: It is compatible with pillow bags, gusset bags, zipper bags, four-side sealed bags and other forms to meet the packaging needs of different markets and customers.

High adaptability and flexibility: It is suitable for materials in various states such as granules, powders, liquids, etc.; it can achieve fast switching by replacing parts or adjusting parameters.

Application industries of Fully automatic weighing packaging machine

Fully automatic weighing packaging machine is widely used in food, chemical, agriculture and medicine industries:

Food industry: widely used for packaging snack foods, seasonings, nuts, rice, frozen foods, etc., to improve packaging hygiene standards and extend shelf life.

Chemical industry: used for packaging laundry detergents, desiccants, plastic particles, etc., with dust-proof and anti-corrosion design to ensure material safety.

Agricultural field: automatic packaging of bulk materials such as seeds, fertilizers, and feeds to improve packaging efficiency and reduce labor intensity.

Pharmaceutical industry: suitable for precise packaging of granules and powder drugs, meeting the high standards of precision and pollution-free in the pharmaceutical industry.

Fully automatic weighing packaging machine case

The following are examples of the use of Fully automatic weighing packaging machine in materials of different shapes.

Particle materials: In the feed industry, the fully automatic particle packaging machine adopts double spiral feeding + pneumatic bag clamping technology to achieve precise packaging of 5-50kg/bag. The company has configured a high-speed bag sewing machine (speed ≥ 15 bags/minute) to make the production line efficiency reach the industry-leading level.

Strip materials: For strips such as quick-frozen meatballs, the 14-bucket computer combination scale uses multi-channel synchronous weighing to solve the problem of easy material jamming and slow speed of traditional single-bucket scales. In actual applications of food companies, the packaging speed reaches 80 bags/minute, and the weight error is stable within ±1g.

Flake materials: The pharmaceutical industry has extremely high requirements for the cleanliness of tablet packaging. A company uses a 304 stainless steel body + clean room design, combined with a visual inspection system to achieve tablet counting and missing tablet detection, and the product qualification rate is increased to 99.98%.

Special-shaped materials: In the hardware industry, the fully automatic packaging machine completes the directional bagging of special-shaped parts such as screws and nuts through vibration plate sorting + robotic arm grabbing technology. Customized equipment in the company supports mixed loading of more than 10 accessories, and the filling time of a single bag is shortened to 3 seconds.

Fully automatic weighing packaging machine packaging samples

Fully automatic weighing packaging machine manufacturers

Fully automatic weighing packaging machine manufacturers are all over the world, covering all kinds of manufacturers from small customized equipment to large fully automated production lines. When choosing suppliers, enterprises need to consider: technical strength and R&D capabilities. Manufacturers with accumulation and strong R&D have more advanced and intelligent equipment, with functions such as automatic fault detection; customized services can configure equipment according to customer-specific needs to improve production efficiency and packaging accuracy; after-sales service, high-quality service can ensure long-term stable operation of equipment; production experience, manufacturers with many years of industry experience have more stable and reliable equipment, and can quickly adapt to the market to launch new products. Our factory can be customized according to model, function, etc., and can carry materials for trial operation, focusing on the production of different types of packaging machines.

Related news

- Fully Automatic Vertical Molding Soft Candy Packaging Machine Introduction

- Fully Automatic Vertical Molding Soft Candy Packaging Machine

- Fully Automatic Vertical Molding Granule Packaging Machine

- Fully Automatic Small Bag Powder Packaging Machine

- Vertical Form Fill Seal Packing Machines Suppliers

- Vertical Form Fill Seal Packing Machines Price

- Fully automatic batching packaging machine price

- Fully automatic chemical packaging machine price