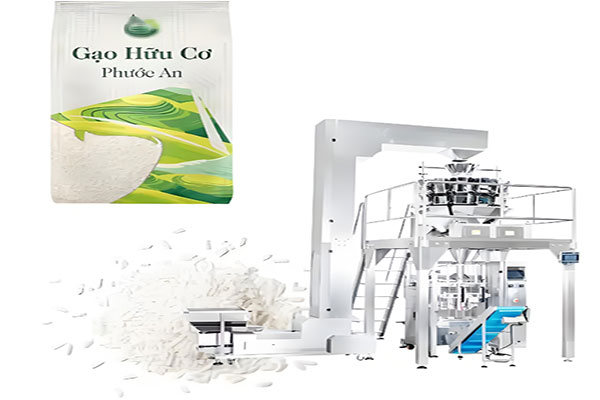

Fully automatic metering packaging machine

Fully automatic metering packaging machine integrates automatic metering, conveying and packaging. The output is generally 20 to 100 bags per minute, In terms of price, the basic model starts at about US$15,000, and the high-end configuration model can reach more than US$50,000

Measuring accuracy: within ±1.0%

Packaging range: 100g–5kg

Operating system: PLC control

Packaging speed: 20–80 bags/minute

Bag width support: 80–220mm

Power supply requirements: 220V/380V

What is Fully automatic metering packaging machine?

Fully automatic metering packaging machine integrates automatic metering, conveying and packaging. It can accurately pack powders, granules, liquids and other materials according to set parameters, and automatically complete bag making, filling and sealing. Compared with manual metering, it greatly reduces errors and improves efficiency and consistency. The equipment is equipped with high-precision sensors, metering systems and PLC controllers to achieve high-speed and stable operation. The equipment supports the production and adaptation of a variety of bag types, including pillow bags, self-supporting bags, three-side sealed bags, four-side sealed bags, and continuous bag packaging. The output is generally 20 to 100 bags per minute, suitable for a variety of industries. In terms of price, the basic model starts at about US$15,000, and the high-end configuration model can reach more than US$50,000, depending on the metering accuracy, packaging speed and functional configuration.

Fully automatic metering packaging machine uses high-precision sensors and control systems to achieve automated processes: after the material is metered by the feeding system, it is made into packaging bags by the former, the sensor triggers the filling mechanism to complete the material feeding, the heat sealing device seals the bag opening, and finally the cutting mechanism divides the finished product and outputs it. Each link is coordinated by the PLC to achieve continuous and rapid packaging.

The core role of metering technology in Fully automatic metering packaging machine

In the packaging process, the accuracy of metering technology directly affects the weight standard and product quality of the packaging. Fully automatic metering packaging machine uses a variety of metering methods to meet the needs of different materials:

Electronic weighing metering: Real-time monitoring of material weight through high-precision electronic scale sensors to achieve an error within ±0.1%. Suitable for solid materials such as particles and powders.

Volume metering: Packing materials based on preset volumes, mostly used for fluids or viscous materials.

Screw metering: Use a screw propeller to control the material delivery volume, suitable for powders and particles.

Weighing feeding: Combine sensors and conveying devices to achieve dynamic metering, with strong adaptability.

Typical technical parameters of Fully automatic metering packaging machine

Fully automatic metering packaging machine supports a variety of bag types and materials, accurate measurement, packaging range 5kg-10kg, the following are the relevant parameters of different models as follows:

| Model | Bag size(mm) | Metering range(g) | Packaging speed(bags/min) | Control motor |

| CF6-200B | W:100-200mm L:100-300mm | 50-1500 | 25-45 | Can adjust bag width automatically |

| CF8-200B | W:100-200mm L:100-300mm | 50-1500 | 25-45 | 1. Can adjust bag width automatically 2. With zipper open function |

| CF6-300 | W:200-300mm L:200-450mm | 1000-3000 | 20-40 | Can adjust bag width automatically |

| CF8-300 | W:200-300mm L:200-450mm | 1000-5000 | 20-40 | 1. Can adjust bag width automatically 2. With zipper open function |

| CF6-400 | W:260-400mm L:320-600mm | 5000-10000 | 10-20 | 1. Can adjust bag width automatically 2. Can feed bag with plastic handle |

Fully automatic metering packaging machine price range

Depending on the function, output, material type and brand, the price range of Fully automatic metering packaging machine is relatively large. The general price range on the market is as follows:

Basic equipment

The functions are relatively simple, suitable for packaging dry powder or granular materials, with a packaging speed of 20-40 bags/minute, and basic metering accuracy, suitable for small enterprises or start-ups. The price of such equipment is generally between US$12,000 and US$20,000.

Mid-range equipment

It has high metering accuracy (within ±0.3%), supports a variety of packaging bag types and materials, including liquids, sauces, etc., and the packaging speed can reach 50-80 bags/minute. Suitable for medium-sized production lines, with PLC control and touch screen operation, the price is usually in the range of US$20,000 to US$35,000.

High-end intelligent equipment

Equipped with servo motor drive, multi-point automatic metering, multi-language touch screen, automatic bag changing and remote monitoring functions, it can meet the precise metering and high-speed packaging needs of complex materials, with a speed of more than 100 bags/minute, suitable for large enterprises and customized production. The price of such equipment is generally between $35,000 and $60,000 or more.

Special customized equipment

Wear-resistant and anti-clogging systems designed for special materials (such as materials that are easy to agglomerate, highly corrosive or highly viscous), or production lines with multi-link linkage functions, will cost more, usually more than $50,000, and the specific price needs to be customized according to customer needs.

Fully automatic metering packaging machine workflow

The Fully automatic metering packaging machine consists of a metering system, a packaging head, a conveying system and a control system, and is highly automated as a whole. Its standard workflow is as follows:

Material conveying: The raw materials are fed from the silo into the metering system by a conveying device.

Automatic metering: According to the set parameters, the equipment automatically completes weighing or volume measurement.

Bag preparation: Automatically generate or open packaging bags through roll film forming or pre-made bag systems.

Filling materials: The metered materials are accurately filled into the bag to ensure consistency.

Sealing and cutting: The equipment performs heat sealing, coding and bag cutting to complete the packaging of the finished product.

Finished product output: The packaged products are output via a conveyor belt for easy stacking and subsequent processing.

Fully automatic metering packaging machine case