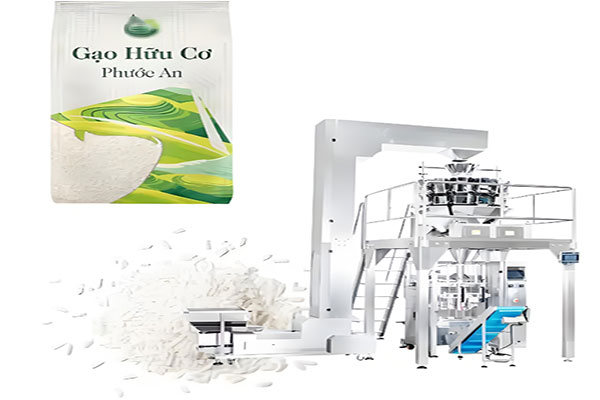

Fully automatic filling packaging machine

Fully automatic filling packaging machine price generally USD $4,000–$12,000. The packaging speed of conventional models is 20–60 bags per minute, and the high-speed model can reach up to 100 bags/minute.

Filling range: 50g–10kg

Material types: fluid, sauce

Filling speed: 15–50 times/minute

Power supply voltage: 220V single phase

Contact material: 304 stainless steel

Control system: servo drive

Cleaning method: detachable pipe

What is a fully automatic filling packaging machine?

Fully automatic filling packaging machineis a key equipment in modern industrial packaging lines. It integrates automatic feeding, precise filling, quantitative filling, packaging, bag cutting and coding. It is widely used for rapid packaging of various materials such as liquids, pastes, powders and granules. Its filling system can be equipped with piston type, screw type or electronic weighing method according to the characteristics of the material to ensure high precision and stability of the filling process. The packaging speed of conventional models is 20–60 bags per minute, and the high-speed model can reach up to 100 bags/minute, which greatly improves the efficiency of the production line. The price of the equipment varies depending on the configuration, generally USD $4,000–$12,000, and the high-end customized model can reach more than USD $20,000.

The working process of the fully automatic filling packaging machine is: after the equipment is started, the automatic feeding system accurately transports the material to the filling area. According to the characteristics of the material, select the appropriate metering method such as piston type for accurate filling and quantitative filling. After filling, quickly seal, then cut the bag into shape, and finally the coding machine clearly codes on the package.

Fully automatic filling packaging machine's various packaging forms

Fully automatic filling packaging machine supports a variety of packaging bag types, common bag types include pillow bags, stand-up bags, zipper bags, three-side sealed bags, four-side sealed bags, etc., which are suitable for different product characteristics and market needs.

Pillow bag: suitable for powder and granular materials, simple structure, low cost, common size is 80-200mm wide and 100-300mm long.

Stand-up bag: the bottom of the bag can be propped up, suitable for liquid and sauce products, easy to display, common capacity is 200ml-1000ml.

Zipper bag: with repeated opening function, suitable for snacks, coffee, health products, sealing width 8-10mm.

Three-side seal bag: suitable for small-sized packaging, good sealing performance, bag width can reach within 150mm.

Four-side seal bag: commonly used for medicine and condiments, with regular appearance, uniform sealing, and support for multi-channel filling.

Fully automatic filling packaging machine classification

Fully automatic filling packaging machine can be divided into four types according to material characteristics and production needs:

Liquid filling machines use normal pressure, pressure or vacuum technology, suitable for liquid products such as milk and wine, and the output of a single machine can reach 2000-10000 bottles per hour, meeting the needs of medium and high-speed production lines;

Paste filling machines use piston pumps or servo motors to accurately control high-viscosity materials (such as toothpaste and skin care products), and the output is usually 800-5000 tubes per hour, taking into account both accuracy and efficiency;

Powder filling machines use spiral propulsion or vacuum suction technology to achieve dust-free filling of powders such as flour and milk powder, with an output range of 600-4000 bags per hour, suitable for different packaging specifications;

Particle filling machines use vibration plates or measuring cups to pack granular materials such as candies and medicines, with an output of 1500-8000 boxes per hour, supporting fast switching of multiple specifications. Through modular design, various machine models can flexibly match the production capacity needs of enterprises.

Fully automatic filling packaging machine intelligent control system

Fully automatic filling packaging machine is equipped with touch screen and PLC programmable controller, supporting multi-language operation interface. It has the following functions:

Touch screen and PLC control: support multi-language operation, simple interface, easy operation, and improve the level of automation management.

Automatic fault alarm shutdown: built-in sensors monitor bag shortage, filling abnormality and other faults in real time, automatically alarm and shut down to prevent losses.

Production data statistics: record output, number of faults and running time, and data can be exported for production analysis and optimization.

One-key parameter switching: preset multiple groups of packaging parameters, one-key switching of different materials and bag types, shortening production change time.

Remote monitoring and Internet of Things: support Ethernet and Wi-Fi remote connection, realize remote diagnosis and access to factory intelligent system, convenient maintenance and management.

Technical parameters of Fully automatic filling packaging machine

| Name | Parameter |

| Power | 220W |

| Weight | 55kg |

| Dimensions | 450*520*1600mm |

| Capacity | 2-50g |

| Film width | 12cm |

| Bag Length | 8 cm |

| Packing material | Film, aluminum foil, filter papaer |

Price range of Fully automatic filling packaging machine

The price of fully automatic filling packaging machine varies greatly according to functional configuration, material, speed and degree of customization. The general price range is as follows:

Basic equipment: with standard automatic filling, sealing, and bag cutting functions, suitable for simple material packaging, the price is about USD $4,000-$7,000.

Mid-range multifunctional equipment: equipped with intelligent control system, multiple metering methods and auxiliary modules, with a wider range of applications, the price is between USD $7,000-$12,000.

High-speed and high-configuration customized type: using servo drive, multi-station linkage and remote monitoring to meet mass production and complex processes, the price can reach more than USD $20,000.

Fully automatic filling packaging machine procurement suggestions

When selecting equipment, the following points should be considered:

Material characteristics: clarify the nature of the material, such as liquid, paste, powder or granule, and its viscosity, corrosiveness and particle size, and select the appropriate filling system (piston type, screw type or electronic weighing).

Packing capacity and speed requirements: determine the single bag capacity range and production speed target to ensure that the equipment meets the production requirements and avoid insufficient production capacity or waste.

Packaging bag type and specifications: Select the appropriate packaging bag type (pillow type, vertical bag, zipper bag, etc.) according to product characteristics, and confirm that the equipment supports the corresponding bag width and length range.