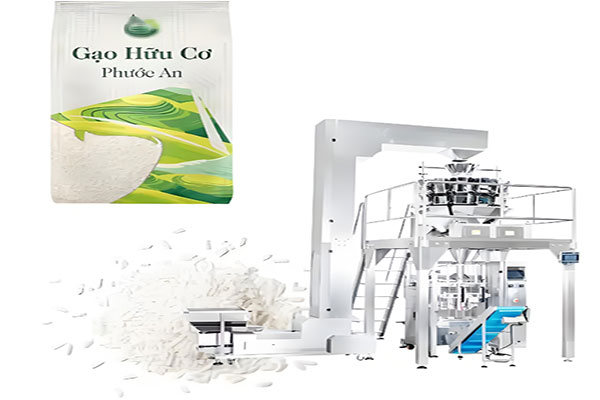

Fully automatic chemical packaging machine

The price range of Fully automatic chemical packaging machine is 8000-300,000 USD. This equipment is an important equipment in the chemical industry, designed for the metering, mixing and packaging of chemical materials such as granules, powders and liquids. Packaging range: 5-50 kg Packaging speed: 1000-10000 bags/hour Weighing error: within ±0.3% Material configuration: corrosion-resistant stainless steel Applicable materials: powder/granules/liquids Gas source requirements: above 0.6MPa

What is Fully automatic chemical packaging machine?

Fully automatic chemical packaging machine is an important equipment in the chemical industry, designed for the metering, mixing and packaging of chemical materials such as granules, powders and liquids. This equipment strictly follows the safety standards of the chemical industry and can effectively deal with special chemical materials such as corrosive, flammable and toxic materials. The output per hour reaches 1000-10000 pieces, and the price range is 8000-300,000 USD. Its core advantage is that it can ensure the safety and stability of the chemical product packaging process, reduce the risk of manual contact, and achieve high-precision measurement of ±0.3%, improve production efficiency and packaging quality, and reduce material loss.

The working process of the Fully automatic chemical packaging machine is as follows: the material is accurately measured by the feeding system and sent to the packaging position, the packaging material is processed to form a bag, the sensor triggers the filling, the heat sealing device seals the bag mouth, the cutting mechanism cuts the finished product, and finally the conveyor belt sends the finished product out. The whole process is coordinated by the control system to achieve unmanned operation.

What are the core functions of the Fully automatic chemical packaging machine?

The Fully automatic chemical packaging machine has functions such as automatic feeding, automatic feeding, material filling, and bag mouth dust removal:

Automatic feeding: equipped with a screw conveyor or a vacuum suction machine, the equipment can select different forms of feeding methods according to the characteristics of chemical raw materials, which can prevent dust from overflowing and ensure a continuous and smooth feeding process.

Measuring and weighing: using high-precision sensors and intelligent algorithms, the packaging error is controlled within ±1%. The system supports automatic calibration function, which can automatically adjust parameters according to the set target to adapt to packaging requirements of different weight specifications.

Material filling: You can choose a falling, spiral or vibrating feeding device according to the material characteristics to adapt to a variety of material forms. Whether it is powder, granules or a mixture with poor fluidity, the equipment can fill it quickly and smoothly.

Bag mouth dust removal: Effectively remove dust from the sealing part to ensure clean sealing and improve the quality of the finished product. The dust removal system is linked with the sealing station to ensure that the bag mouth is thoroughly cleaned before sealing to avoid loose sealing or poor product appearance due to residual dust.

Fully automatic chemical packaging machine parameters

Fully automatic chemical packaging machine parameters : the equipment has a daily output of ≥4.8 tons, a speed of 10-40 bags/minute, and an accuracy of ±0.5%-1%. It is suitable for 10-5000g materials and supports a variety of bag types such as pillow bags, gusset bags, four-side seals, and five-side seals. Compatible with bag width 60-500mm, bag length 50-800mm, suitable for 320VFFS to 1050VFFS models.

| Model | Equipment Configuration |

| System output | ≥4.8 Ton/day |

| Packing speed | 10-40 bags/min |

| Packing Accuracy | ±0.5%-1% |

| Bag size(mm) |

(W) 60-150 (L) 50-200 for 320VFFS

(W) 60-200 (L) 60-300 for 420VFFS (W) 90-250 (L) 80-350 for 520VFFS (W) 100-300 (L) 100-400 for 620VFFS (W) 120-350 (L) 100-450 for 720VFFS (W) 350-500 (L) 100-800 for 1050VFFS |

| Bag type | Pillow bag/gusset bag/Four edge sealing bag,5 edge sealing bag |

| Weighing range | 10-5000g |

What is the structure of the Fully automatic chemical packaging machine?

The Fully automatic chemical packaging machine is mainly composed of the following main structures: feeding system, metering system, filling mechanism, bag making and sealing device, control system and finished product conveying device. The feeding system often uses screw conveyors, vacuum feeders, etc. to ensure continuous and stable feeding of chemical raw materials; the metering system uses screw weighing or electronic scales according to the characteristics of the material to achieve precise control; the filling part selects a suitable unloading structure according to the material form (powder, granules, crystals, etc.); the bag making and sealing device supports pillow bags, vertical bags, prefabricated bags and other bag types to ensure a firm and leak-proof seal; the control system is usually equipped with PLC and human-machine interface to achieve one-button start and stop, parameter setting and intelligent monitoring; finally, the conveying mechanism completes the finished product output. The modular design of the whole machine structure is easy to maintain and upgrade.

What are the advantages of the Fully automatic chemical packaging machine?

Fully automatic chemical packaging machines have many advantages. First of all, they are highly efficient. The whole line operation is highly automated. From feeding to bag sealing, no manual intervention is required, which greatly improves production speed and stability. Secondly, they are highly accurate. With the intelligent metering system, the error is controlled within ±1%, ensuring the consistent weight of each bag and meeting the industry measurement standards. Thirdly, they are highly adaptable. The equipment is compatible with various forms of chemical materials, such as powder, granules, mixtures, etc., and has wide adaptability. In addition, the packaging is beautiful and the structure is compact, which can effectively prevent dust leakage and ensure the cleanliness of the workshop. In addition, it is equipped with a safety protection system and a fault alarm function, which improves the safety and intelligence level of equipment operation.

Fully automatic chemical packaging machine Applicable materials

Fully automatic chemical packaging machine is suitable for various forms of chemical materials, including powder, granules, crystals and mixtures. Common materials are as follows:

Powders: PVC powder, calcium carbonate, talcum powder, alumina, silicon powder, resin powder, etc., widely used in plastics, building materials, ceramics, coatings and other industries.

Granules: PE granules, rubber granules, dye granules, sodium chloride granules, etc., suitable for plastics, rubber, dyes and other industries.

Crystals: soda ash, borax, sodium sulfate, potassium chloride, etc., suitable for cleaning agents, glass, agricultural chemicals.

Mixed: composite additives, fertilizer premixes, water treatment agents, etc., provide stable feeding and metering solutions for granules and powder mixtures.

Price of Fully automatic chemical packaging machine

The price of Fully automatic chemical packaging machine varies depending on the degree of automation, weighing accuracy, packaging form and selected configuration. The following is a price reference for common configurations:

Small laboratory chemical packaging machine: suitable for the research and development stage of chemical products and small batch trial production scenarios, compact structure, flexible operation, support for multiple material switching, easy to test packaging effects and data collection. The price is about US$8,000-25,000, suitable for scientific research institutions, laboratories and start-ups.

Basic industrial packaging machine: equipped with standard weighing system and sealing module, suitable for chemical enterprises with medium production capacity, and can meet the daily packaging needs of most powder and granular raw materials. The output can reach 2,000-5,000 pieces per hour, and the price is between US$25,000-100,000, which is cost-effective and suitable for conventional industrial production.

High-end intelligent packaging production line: with intelligent functions such as automatic batching, weighing, packaging, online detection, coding and data traceability, the system can be connected with MES or ERP platform to realize full process monitoring and quality management. It is suitable for large-scale chemical production lines, dangerous goods packaging and enterprises with extremely high requirements for efficiency and safety, with a price range of US$100,000-300,000.