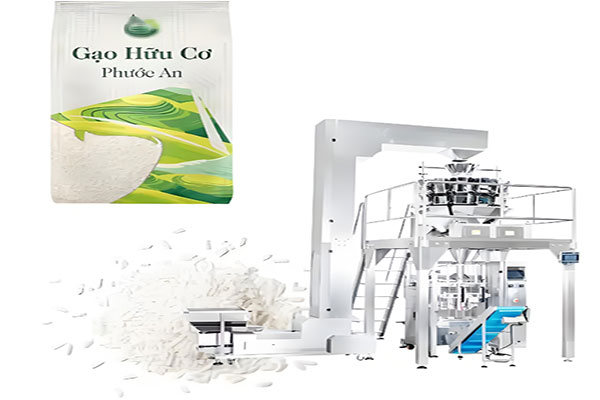

Fully automatic batching packaging machine

Fully Automatic Batching Packaging Machine is generally between USD$7,000 and $20,000, and the specific price will vary according to parameters, materials and usage scenarios. The equipment has functions such as batching, weighing, bagging, and sealing. Control system: PLC+touch screen Weighing range: 100g–50kg (optional customization) Power requirement: AC 380V/50Hz, power 4.5–7kW Packaging speed: 15–60 bags/minute (depending on the material and packaging form) Batching type: 2–10 materials can be freely set Gas source requirement: 0.6MPa, gas consumption 0.4m³/min

What is Fully automatic batching packaging machine?

Fully automatic batching packaging machine includes functions such as automatic batching, quantitative weighing, automatic bagging and sealing. The equipment supports the setting of multiple material mixing ratios, and has functions such as high precision (±0.2%), high efficiency (20-60 bags/minute), automatic deviation correction, and automatic cleaning. The packaging capacity range is usually 100g-50kg, suitable for a variety of bag types such as flat bags, self-supporting bags, etc. The equipment output ranges from 500kg to 5 tons per hour depending on the model. The power supply is mostly 220V/380V, the power is about 2.5kW, and the air source requirement is 0.6MPa. The price is usually between USD$7000-$20000.

Fully Automatic Batching Packaging Machine realizes continuous packaging of materials through automatic feeding, weighing, mixing, bag making, filling, sealing and bag cutting processes. The equipment adopts PLC intelligent control system, multi-head combination scale for precise measurement, and cooperates with spiral conveyor or vibration feeding mechanism to complete the rapid mixing and automatic packaging of materials.

What are the models of Fully automatic batching packaging machine?

Fully automatic batching packaging machine can be divided into three categories according to output: small, medium and large, to meet the production capacity needs of different enterprises.

Small equipment has an output of 100-300 kg/hour, suitable for laboratories, small workshops or start-ups. Generally, it is equipped with 1-2 metering systems, with a packaging capacity of 1-5kg/bag, compact structure, small footprint, and commonly used models such as DHB-1S, equipped with a 0.5m³ mixing silo, and a power of about 1.5kW.

The output of medium-sized equipment is 300-1000 kg/hour, suitable for medium-sized food, chemical or feed production enterprises. Typical models such as DHB-2M have 2-3 independent weighing and mixing systems for materials, a packaging range of 5-25kg/bag, equipped with a PLC control system and a Z-type elevator, and a power of about 2.2-3kW.

The output of large-scale equipment can reach more than 1000 kg/hour, and is mostly used for large-scale continuous production. Models such as DHB-4L support precise proportioning of 4 materials at the same time, and the packaging range can be expanded to more than 50kg/bag. It is suitable for automatic sealing machines, conveyor lines and automatic palletizing systems, with a power of more than 5kW, and the entire line can be unmanned.

What are the main features of Fully automatic batching packaging machine?

The fully automatic batching packaging machine has the main advantages of high automation, high batching accuracy, and compatibility with a variety of bag types.

Precise batching, small error: built-in high-precision weighing sensor and intelligent control system, can achieve accurate measurement of grams or even milligrams, ensure formula consistency and product quality, especially suitable for industries with strict requirements on proportion, such as food additives, medicines, premixes, etc.

Compatible bag type: the equipment supports a variety of bag types (such as pillow bags, gusset bags, four-side sealed bags), and can adjust the production capacity specifications to meet the diverse requirements of different market needs.

High degree of automation, reduced manual intervention: from automatic feeding and weighing of raw materials to feeding and mixing, the entire batching process is fully automated, without manual intervention, avoiding human errors and cross contamination, especially suitable for powders, granules and other materials that are easy to dust or require strict hygiene control.

Technical parameters of Fully automatic batching packaging machine

The core parameters of conventional Fully automatic batching packaging machine are the maximum roll film width between 220mm-420mm, the filling range is adapted according to the specific model, the bag length is between 10-260mm, and the equipment weight is 70-101 kg.

| Model | GX-220DKF | GX-320DKF | GX-420DKF |

| Max roll film width | 220mm | 320mm | 420mm |

| Bag Length | 10-150mm | 10-190mm | 10-260mm |

| Bag Width | 20-100mm | 60-150MM | 120-200MM |

| Filling range | 1-99G | 10-500G | 100-1000G |

| Dimension(L*W*H) | 520*420*1590mm | 640*480*1700mm | 890*490*1850mm |

| Power | 220V/110V 50HZ/60HZ 550W | 220V/110V 50HZ/60HZ 600W | |

| Weight | 70KG | 94KG | 101KG |

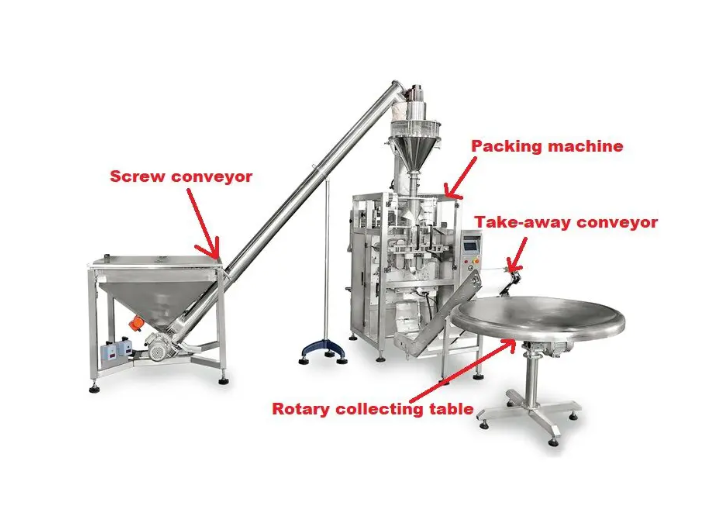

Structure of Fully automatic batching packaging machine

Fully Automatic Batching Packaging Machine is mainly composed of multiple core modules to achieve accurate batching and automatic packaging of materials. Its basic structure includes: material conveying system (such as screw conveyor, Z-type elevator), multi-head weighing system or quantitative weighing device, mixing device (configured according to demand), automatic bag making and sealing system, PLC intelligent control system and finished product output mechanism. Some equipment is also equipped with dust removal device and online detection system to ensure the cleanliness of the packaging process and the consistency of the finished product.

Fully automatic batching packaging machine market price analysis

The market price of fully automatic batching packaging machine is mainly affected by the number of ingredients. Generally speaking, the more ingredients there are, the more complex the structure of the equipment is, and the price increases accordingly.

Powder ingredient packaging machine: suitable for food powder, chemical powder, etc. The basic price is about $8,000 - $15,000, and the output is generally 200-500 bags/hour. The machine structure is relatively simple and suitable for small and medium-sized production.

Granular ingredient packaging machine: suitable for grain, granular feed, plastic granules, etc., the price range is $10,000 - $18,000, and the output is about 300-600 bags/hour. The equipment is equipped with a vibrating feeding system to improve the metering accuracy.

Liquid/paste ingredient packaging machine: for fluid products such as sauces and oils, the price is higher, about $15,000 - $30,000, and the output is 100-300 bags/hour. It needs to be equipped with a well-sealed filling system to prevent leakage.

Fully automatic batching packaging machine manufacturers

Fully Automatic Batching Packaging Machine manufacturers are concentrated in manufacturing countries such as China, Germany, Japan and Italy. Our factory has advantages in the research and development and manufacturing of Fully Automatic Batching Packaging Machine, has rich industry experience and a complete production system, and supports non-standard customization services. According to the specific needs of customers, we can tailor equipment models, output configurations and functional modules, and provide overall solutions from batching system design to packaging process optimization to ensure that the equipment is more in line with actual production scenarios, improve efficiency and packaging accuracy, and help customers achieve automated and precise production goals.

Fully automatic batching packaging machine case

In actual applications, Fully Automatic Batching Packaging Machine widely serves food, chemical, pharmaceutical, feed, building materials and other industries. For example, in the seasoning industry, the Fully Automatic Batching Packaging Machine is used to achieve accurate batching of various materials such as chicken essence, white sugar, and salt, with a daily output of more than 10 tons, greatly improving production efficiency; in the chemical industry, the Fully Automatic Batching Packaging Machine is used for proportional mixing and moisture-proof packaging of various powder additives to ensure material stability and batch consistency; in the premix feed industry, the equipment achieves trace batching and sealed packaging of multiple vitamins and trace elements, with the packaging error controlled within ±0.5%; in the pharmaceutical powder industry, the closed structure and dust removal design are used to ensure the cleanliness of the production environment and the safety of drugs.

Fully automatic batching packaging machine industry application scenarios

Fully automatic batching packaging machine is used in many fields such as food, chemical industry, feed, etc.:

In the food industry, it can be used for precise proportion packaging of various seasonings, compound powders, instant food packages, etc., to ensure that all kinds of raw materials are accurately placed in proportion, suitable for central kitchens, seasoning factories, ready-to-eat food production lines, etc.;

In the chemical industry, it can be used for a variety of powder combination packaging such as washing powder, desiccant, additives, etc., to meet different formulas and special needs such as moisture-proof and sealing, and widely serve fine chemicals, daily chemical processing and other enterprises;

In the feed industry, it is used to prepare protein powder, trace elements, premixes and other products, accurately control nutritional ratios, and improve animal feeding efficiency, especially suitable for aquatic products, animal husbandry, and pet feed production lines;

In the building materials industry, it is mostly used for batch measurement and packaging of putty powder, cement additives, etc., to meet the requirements of automatic feeding, high-precision weighing and dustproof sealing, and to adapt to building materials production lines with strong continuity and large output.

Brief description of the operation process of the fully automatic batching packaging machine

The typical operation process of the fully automatic batching packaging machine is divided into five steps: automatic feeding, precise batching, mixing, automatic packaging, coding and output:

Automatic feeding: The raw materials are transported to each batching bin in turn through a screw conveyor or a vacuum feeder to avoid manual handling, improve feeding efficiency, and ensure that the materials are clean and pollution-free;

Precise batching: The system automatically starts the weighing unit to perform accurate measurement of grams or even milligrams according to the preset formula ratio to ensure that each raw material is put in proportion to achieve high consistency;

Mixing: Multiple materials are fully stirred in the mixing system to form a homogeneous mixing state to ensure that the final product quality is stable, without stratification or deviation;

Automatic packaging: The mixed materials enter the packaging host through the metering hopper to complete the automatic bag making, quantitative filling, sealing and shaping processes, and the packaging is beautiful and firm;

Coding and output: The surface of the packaging bag is automatically sprayed or hot-coded, and the production date, batch and other information can be marked. The finished product is output to the next process via a conveyor belt, such as automatic detection, boxing or palletizing system.