Full Auto Feed Packaging Machine

Full Auto Feed Packaging Machine packaging bag material is highly compatible and supports prefabricated bags (such as PE composite film, aluminum foil bags), woven bags, paper bags and ton bags to meet different specifications and cost requirements. Small equipment can reach 20-60 bags/hour, and medium and large equipment can reach 120-400 bags/minute.The basic model is about US$2,000-5,000, the mid-range model is about US$6,000-9,000, and the high-end customized model can reach US$1,000-20,000. Packaging speed: 30-60 bags per minute Power supply voltage: 220V 50/60Hz Total power: about 3.5 kilowatts Equipment weight: about 800 kg Control system: PLC touch screen operation Sealing method: heat-sealed double-sided sealing Applicable products: food, hardware, small items

What is Full Auto Feed Packaging Machine?

Full Auto Feed Packaging Machine is applicable to granular feed (such as corn, soybean meal pellets), powdered feed (such as fish meal, premix), paste feed (such as pet wet food) and liquid additives. The packaging bag material is highly compatible and supports prefabricated bags (such as PE composite film, aluminum foil bags), woven bags, paper bags and ton bags to meet different specifications and cost requirements. Functionally, the equipment integrates the entire process of automatic bag supply, weighing and metering, filling and sealing, coding and labeling, and finished product transportation. It supports PLC intelligent control and parameter storage, and can quickly switch product specifications. In terms of output, small equipment can reach 20-60 bags/hour, and medium and large equipment can reach 120-400 bags/minute, meeting the needs of small batch customization and large-scale production. The price varies significantly due to the configuration. The basic model is about US$2,000-5,000, the mid-range model is about US$6,000-9,000, and the high-end customized model can reach US$10,000-20,000.

Full Auto Feed Packaging Machine Structure

Full Auto Feed Packaging Machine consists of multiple precision modules to form a complete automated packaging system. The core parts include: automatic feeding device, responsible for the stable transportation of materials; precision metering system, to ensure the consistent weight of each bag of products; bag former, to form the roll film into the required bag shape; transverse and longitudinal heat sealing mechanism to achieve the sealing of the packaging bag; date coding device, to print production information on the product; and finally the finished product output conveyor belt.

What are the advantages of Full Auto Feed Packaging Machine?

The Full Auto Feed Packaging Machine uses a modular structure design to achieve flexible configuration. It supports multiple types of metering devices such as screws, weighing, and volumetric. It can accurately handle multiple materials such as granules, powders, liquids, and pastes. It is compatible with more than ten types of bags and composite film materials such as flat bags, self-supporting bags, and zipper bags. Its PLC control system integrates automatic bag taking, bag opening, filling, sealing, and detection functions. The packaging accuracy reaches ±0.25%-1%, and the maximum speed exceeds 180 bags/minute, which is 3-5 times more efficient than traditional equipment. In terms of bag type, the equipment supports a variety of packaging bag forms, including three-side seals, four-side seals, back seals, self-supporting bags, zipper bags, etc. The bag shape is beautiful and neat, and the seal is firm.

Full Auto Feed Packaging Machine Types

Full Auto Feed Packaging Machine can be divided into a variety of specialized models according to the differences in packaging forms and application scenarios. Each type of equipment has significant characteristics in functional design and applicable fields:

Vertical Packaging Machine (VFFS): It adopts a roll film forming-filling-sealing integrated process, which is particularly suitable for fluid materials such as granules (candy, medicines), powders (milk powder, seasonings) and viscous liquids (jam, shampoo). Its vertical operation mode can save floor space, and high-precision metering of ±0.5g can be achieved through servo system control.

Horizontal Packaging Machine (HFFS): It is designed for regular solid products such as chocolate bars, instant noodles, etc. It adopts a horizontal conveyor belt feeding system with a maximum speed of 200 bags/minute. The unique heat sealing knife structure can handle high-temperature resistant materials such as composite aluminum foil.

Bag Packaging Machine: It uses prefabricated three-dimensional bags for packaging, which is suitable for fragile products (potato chips, puffed foods) and products with brand identification requirements (fine coffee, pet food). The equipment is equipped with a robot automatic bag opening device, and can be equipped with a nitrogen filling or vacuum pumping station, so that the finished package has a strong three-dimensional sense.

Vacuum packaging machine: divided into single-chamber/double-chamber continuous type, it effectively inhibits the growth of microorganisms through -0.1MPa vacuum degree, and is widely used in fresh products such as cold meat and cheese. High-end models integrate a gas ratio mixing system to extend the shelf life of fresh products by 3-5 times.

Multi-column packaging machine: The typical configuration is 4-10 columns operating synchronously, and each column is independently servo-driven, suitable for 0.5-5ml micro-packages (instant coffee, tea powder). The filling amount is adjusted through real-time feedback, and the error is controlled within the range of ±0.1g.

Full Auto Feed Packaging Machine Price

The price of Full Auto Feed Packaging Machine is usually between US$8,000 and US$50,000, depending on the function, brand, production capacity and configuration. For example, medium-sized automatic packaging machines suitable for industries such as food, hardware, and medicine cost between $10,000 and $20,000, while high-end equipment with multi-function weighing, automatic counting, visual recognition, and packaging systems may cost more than $30,000. The actual quotation will also be affected by customization requirements, transportation, and after-sales service. It is recommended to obtain detailed quotations from manufacturers or suppliers based on specific uses.

Full Auto Feed Packaging Machine Supplier

Our factory has core advantages such as rich technical experience and perfect after-sales service in manufacturing Full Auto Feed Packaging Machine. Relying on the technical accumulation of vibration screening equipment for many years, the company accurately masters material conveying and metering technology to ensure high-precision weighing and stable feeding of packaging machines, and the error rate is lower than the industry standard. The company can support non-standard customization of output, function, model, etc., support trial machine with materials, provide full technical training and rapid response support, and ensure that customers' production lines continue to operate quickly.

Full Auto Feed Packaging Machine Parameters

| Model | ZD-320 | ZD-420 | ZD-520 |

| Bag Styles | Pillow Bag, Gusseted Bag | ||

| Bag Width | 70 to 140mm | 80 to 180mm | 80 to 250mm |

| Bag Longth | 80 to 470mm | 80 to 280mm | 80 to 340mm |

| Film width | ≤320mm | ≤420mm | ≤520mm |

| Packaging materials | Pastes,Granules, Powders | ||

| Running Motion | Intermittent | ||

| Working Efficiency | 30-80bags/min | 30-80bags/min | 30-80bags/min |

| Control By | PLC with HMI Touch Screen | ||

| Date Coding | Hot Stamping Coder, Thermal Transfer Coder, Label Applicator | ||

| Power & Voltage | 3KW | 4.5KW | 5.5KW |

| Compress Air | 0.6-0.8 MPa 0.25 M3/min | ||

| Dimensions | 1400*950*1900mm | 1600*1100*1900mm | 1750*1300*1950mm |

| Machine Weight | 550 KGS | 750 KGS | 1000 KGS |

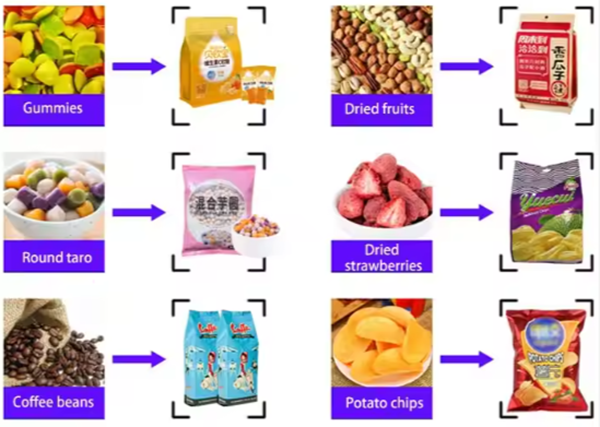

Full Auto Feed Packaging Machine Applicable Fields

Full Auto Feed Packaging Machine has a wide range of materials, covering almost all dry solid materials. In the food industry, it is suitable for packaging rice, flour, sugar, coffee beans, nuts, biscuits, puffed food, etc.; in the pharmaceutical field, it can be used for packaging granular medicines, Chinese herbal medicine slices, medical dressings and other products; in agriculture, it is suitable for quantitative packaging of materials such as seeds, fertilizers, and feed; in the daily chemical industry, it can package products such as washing powder, soap particles, and bath salts. Specially designed models can also handle materials with a certain degree of viscosity or products that require nitrogen filling for preservation. The equipment can adapt to the characteristics of different materials and achieve the flexibility of one machine for multiple uses by adjusting the vibration feeding device, changing the spiral metering mechanism, or replacing the filling nozzle.