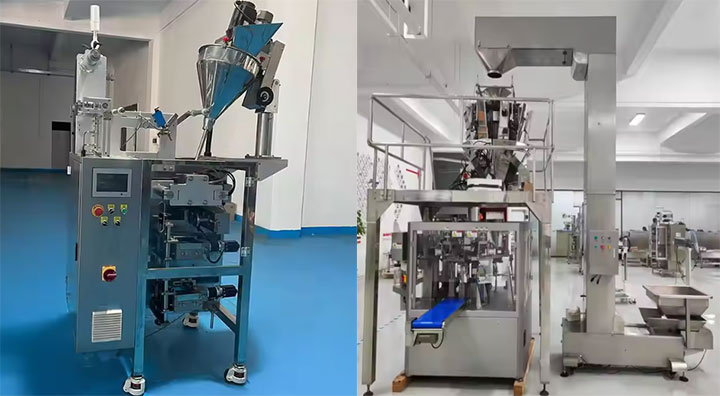

Economic Packaging Machine

Economic Packaging Machine is used to package common materials such as granules, powders, and liquids. Its output is usually 10 to 60 packages per minute. The price of a small machine is about US$1,500 to US$3,000, and the price of a medium-sized machine is US$3,000 to US$6,000 Packaging speed: 20-60 packs/minute Power supply voltage: 220V/50Hz Equipment power: 1.5 kilowatts Packaging size: customizable Applicable film material: PE/PET composite film

What is Economic Packaging Machine?

Economic Packaging Machine is an automated packaging equipment designed for small and medium-sized enterprises or start-up production lines. It has the characteristics of compact structure, stable operation and affordable price. This series of equipment is mainly used for packaging common materials such as granules, powders, and liquids. Common models include: small granule packaging machine, powder packaging machine, liquid packaging machine, vertical bag making machine (VFFS) and pillow packaging machine. Its output is usually 10 to 60 packs/minute, which is suitable for daily medium and low-speed production. In terms of price, depending on the functional configuration and degree of automation, the price of a small machine is about US$1,500 to US$3,000, the price of a medium-sized machine is US$3,000 to US$6,000, and the price of a machine with a multi-head scale and high-speed device is about US$6,000 to US$10,000.

Common Models of Economic Packaging Machine

Economic Packaging Machine includes a variety of common models. Each model is designed for different types of materials and is suitable for diverse packaging needs.

Small granule packaging machine: suitable for free-flowing granules such as melon seeds, candies, and seasonings, with high cost performance. The output is about 10 to 30 bags/minute.

Powder packaging machine: suitable for non-flowing powders such as flour, milk powder, and coffee powder, equipped with a screw metering device. The output is about 10 to 25 bags/minute.

Liquid packaging machine: can package soy sauce, detergent, seasoning sauce, etc., and uses a piston pump or gear pump for quantitative measurement. Output is about 12 to 30 bags/minute.

Vertical Forming Bag Making Machine (VFFS): Automatically completes bag making, filling, and sealing, suitable for packaging a variety of materials. Output is about 20 to 60 bags/minute (depending on the material and configuration).

Pillow Packaging Machine: Suitable for fast packaging of independent products such as masks, biscuits, soaps, etc., with beautiful sealing. Output is about 30 to 100 bags/minute (high-efficiency models can reach 120 bags/minute).

Multi-row strip packaging machine: widely used in small strip packages such as coffee bars, sugar bags, and seasoning powder. The output is about 30 to 40 bags/minute per row, and the 4-row model can reach 120 to 160 bags/minute.

Price of Economic Packaging Machine

The price of Economic Packaging Machine varies significantly depending on the model and function, and the price range is between US$1,000 and US$60,000.

Small semi-automatic powder filling machine

Price range: 1,000 - 3,000 USD.

Structure: The basic model consists of a hopper, a spiral metering device, a manual filling head, a foot switch/button control and a simple frame, and the material is mostly carbon steel or partially stainless steel.

Function: Suitable for quantitative filling of powdered materials (such as milk powder, medicine), relying on manual bagging or containers, with a metering accuracy of ±1%-2%, and a production capacity of about 10-30 bags/minute. The advantages are low cost and easy operation, which can meet the needs of small batches and multiple varieties of powder filling. But the efficiency is low.

Medium-sized fully automatic vertical packaging machine

Price range: 8,000 - 25,000 USD.

Structure: Integrated automatic bag maker, servo drive system, PLC control panel, photoelectric tracking device and stainless steel conveyor belt, supporting automatic film forming.

Function: It can complete the integration of bag making-filling-sealing, suitable for particles and liquids (such as snacks, shampoo), with a production capacity of 50-200 bags/minute. Standard temperature control and date printing, some models include simple weighing or atmosphere preservation function, suitable for standardized production lines.

High-end multifunctional pre-made bag packaging machine

Price range: 20,960 - 60,000 USD

Structure: Modular design, including robot bagging mechanism, multi-station weighing sensor, visual inspection system, touch screen HMI and all-stainless steel body, supporting quick mold change.

Function: Compatible with a variety of bag types (self-supporting bags, four-side sealing), accuracy of ±0.1%-0.5%, and production capacity of more than 300 bags/minute. Integrated foreign body detection, traceability inkjet printing, data networking, suitable for high-demand fields such as medicine and high-end food, high degree of automation, reducing manual dependence.

How to choose Economic Packaging Machine?

To choose a suitable Economic Packaging Machine, you should consider the following aspects in combination with output, product type, site space and budget:

Divided by output:

Small production line (10-20 packs/minute): Small granule or powder packaging machine is recommended, with simple structure and low price, suitable for trial production or e-commerce orders, and the price is between 1500 and 2500 US dollars.

Medium production capacity (20-40 packs/minute): It is recommended to use a vertical packaging machine + electronic weighing or measuring cup combination, which is suitable for conventional product lines, and the price is about 3000 to 5000 US dollars.

High output (40-60 packs/minute): VFFS + multi-head weighing or multi-row strip packaging machine can be selected, which is suitable for large-scale rapid packaging, and the price is more than 6000 to 10000 US dollars.

Select by enterprise type:

Self-employed, e-commerce store: Small equipment is preferred, which occupies a small area, is easy to operate, and has low start-up capital.

Small and medium-sized factories: It is recommended to use medium-sized equipment to support continuous and stable production and higher efficiency.

Large enterprises or OEM factories: You can consider configuring high-speed models, integrating automatic feeding, weighing, printing, conveying and other functions to achieve automated assembly line docking.

What are the advantages of Economic Packaging Machine?

Economic Packaging Machine has structural advantages such as modular design, compact size and easy operation. The price is much lower than that of high-end packaging lines, suitable for small and medium-sized enterprises and trial production, with strong versatility and outstanding economic practicality.

In terms of structural advantages, Economic Packaging Machine adopts modular design, the whole machine is compact, occupies a small area, and is easy to move and install. The control system generally adopts PLC+touch screen operation, with an intuitive interface and convenient adjustment. Most models are equipped with Chinese and English language options, suitable for different operators. The main material of the equipment is 304 stainless steel, which is corrosion-resistant, easy to clean, and meets food-grade production standards.

The price advantage is particularly prominent. Compared with high-end automated packaging lines that cost tens of thousands of dollars, Economic Packaging Machine can achieve stable and efficient packaging needs at a lower cost, which is an ideal choice for small and medium-sized enterprises, individual merchants or trial production stages. Its maintenance cost is low, and its vulnerable parts are highly versatile, making it more economical and reliable for long-term use.

Technical parameters of Economic Packaging Machine

The following are common technical parameters of Economic Packaging Machine, and the specific data may vary slightly depending on the model:

| Metering Mode | Auger filling, Loading cell |

| Package Weight | 5kg / 10kg / 15kg / 20kg / 25kg / 50kg or customized |

| Materials | SS304 / SS316L / Carbon steel |

| Package Accuracy | ±0.2-1%(according to the material) |

| Packaging Speed | 2-10bags/min(according to the material) |

| Power Supply | 220V,380V,480V or customized |

| Hopper Volume | 50L |

| Total Power | 5Kw |

| Overall Dimensions | 1000×900×2150mm or customized |

| Operational Style | PLC control system,Colorful touch screen |

Optional devices

| Gusset device | Nitrogen charging device |

| Chain bag | vibrating device |

| Punching device | Sealing device |

| Exhaust/Inflatable devices | Easy tear device |

| PE film sealing | Bag support device |

| Anti-Static electricity | Evacuating device |

| Horizontal seal cooling blowing device | Film rectify deviation adjust device |

| Automatic feeding device |

Common related equipment

| Multihead weigher/Liner weigher | Cup measuring machine |

| Auger filler | Liquid pump |

Application of Economic Packaging Machine

From the material perspective, Economic Packaging Machine is suitable for a variety of products, such as granules (grains, feed), powders (condiments, milk powder), liquids (sauces, detergents) and small pieces of solids (candy, hardware). It has strong versatility and can adapt to the characteristics of different materials (such as fluidity and density) by adjusting parameters to ensure packaging accuracy and efficiency and reduce waste of consumables.

From the perspective of bag type, the machine supports a variety of common bag types, such as back-sealed bags, three-side sealed bags, four-side sealed bags and self-supporting bags, and can customize special-shaped bags (such as packaging with zippers or mouths). By changing the mold or adjusting the bag-making program, the bag type can be quickly switched to meet the needs of different scenarios such as retail and industrial packaging, with both cost-effectiveness and flexibility.