Small Belt Conveyor Price

Wednesday December-03 2025 17:30:53

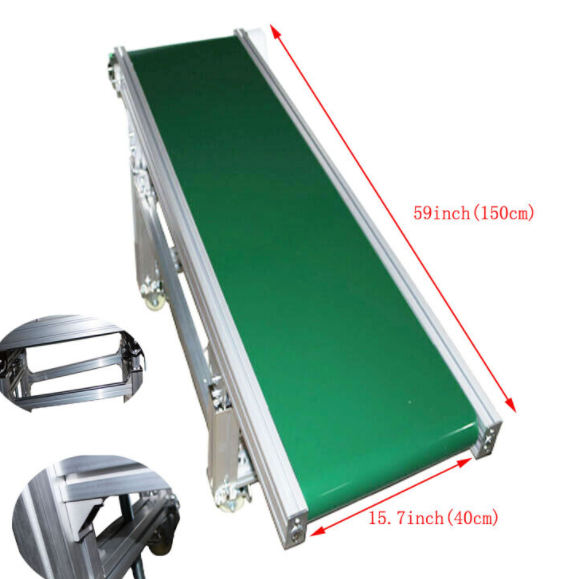

Small Belt Conveyor Price range from $100 to $4,500. Common types include stationary, mobile, and climbing types, each with its specific application scenarios and corresponding price range. The specific cost of a small belt conveyor is typically affected by factors such as its length, width, conveyor belt material, and frame material.

Small Belt Conveyors are available in two installation types: horizontal and inclined. Horizontal conveyors are suitable for short-distance transport, typically 3-20 meters. Inclined conveyors can lift materials 1-5 meters high, with an inclination angle usually not exceeding 20° to ensure smooth material transport and prevent slippage. Belt widths range from 200-500 mm, operating speeds are generally 0.5-1.5 m/s, and conveying capacities vary from 50-500 kg/hour depending on the material type and belt width. The price range for small belt conveyors varies depending on the specific model.

What are the types of Small Belt Conveyor?

Small belt conveyors are commonly available in two types,mobile and inclined. Mobile conveyors can be moved according to working conditions and cost approximately $400 to $1,100. Inclined conveyors can carry hoppers during material lifting, and with skirted patterns, they can handle materials that are prone to rolling and reduce dust. They cost $1,400 to $3,500.

Mobile belt conveyor

Mobile belt conveyors are usually equipped with wheels or crawlers at the bottom to facilitate movement between different work locations. This type of conveyor is more common in situations where the working position needs to be changed frequently, such as dock loading and unloading, construction site stacking, grain transfer, etc.

Wheeled mobile conveyor: The price varies greatly depending on the conveying length and whether it has a lifting function. Short-distance (5-10m) wheeled conveyors without lifting functions are cheaper. Wheeled conveyors with hydraulic or electric lifting functions and a length of 10-20m or even longer are more expensive. Lifting function, conveyor belt width, drive power and the degree of automation of the whole machine are the main factors affecting its price.

Climbing belt conveyor

Climbing belt conveyors are designed for conveying materials at an inclined angle. In order to prevent the material from sliding down, the conveyor belts of this type of conveyor usually have anti-slip patterns, sidewalls or partitions.

Patterned belt conveyor: suitable for scenes with small inclination angles (usually less than 20 degrees). Its price will be slightly higher than that of ordinary flat belt conveyors under the conditions of the same conveying length and bandwidth, depending on the pattern type and the overall configuration of the conveyor.

Belt conveyor with sidewalls/partitions: When the inclination angle is large (up to 30 degrees or even higher), sidewalls or partitions need to be installed to fix the material. The conveyor belt manufacturing process of this type of conveyor is more complicated, so the price will increase significantly. It depends on the height and material of the sidewall/partition and the overall structure of the conveyor.

What are the factors that affect Small Belt Conveyor Price?

Small Belt Conveyor Price is not determined by a single factor, but rather by a combination of factors, including the length and width of the conveyor belt, its materials, frame materials, and structure. The following are the main factors influencing its price:

Conveyor length and width

Length: The length of the conveyor directly affects the frame material, the amount of conveyor belt, the number of rollers and the required drive power. The longer the length, the more materials are required, the higher the manufacturing cost, and the price increases accordingly.

Width: The width of the conveyor belt determines the carrying capacity of the conveyor. The larger the width, the material cost of the conveyor belt, the size and strength requirements of the rollers will increase, thereby pushing up the overall price.

Conveyor belt material

PVC conveyor belt: The price is relatively economical and suitable for general material transportation, such as packaging, light industrial products, etc.

Rubber conveyor belt: It has relatively good wear resistance, corrosion resistance and high temperature resistance, and is suitable for heavy industrial fields such as mining and building materials. The price is usually higher than PVC belt.

PU conveyor belt: It has the characteristics of oil resistance, cutting resistance, and food grade. It is often used in industries with high requirements for sanitary environment. The price is usually higher than PVC and rubber belts.

Special conveyor belts: such as high temperature resistant, flame retardant, anti-static, patterned, with sidewalls or partitions, due to their special manufacturing process and performance, the price will be higher.

Frame material and structure

Carbon steel: The most commonly used frame material, moderately priced, the surface can be sprayed and painted to prevent corrosion.

Stainless steel: It has good corrosion resistance, is easy to clean, and the price is much higher than carbon steel. Stainless steel can be further divided into different grades such as 304 and 316, among which 304 and 316 are more expensive because they have better corrosion resistance.

Aluminum alloy: Lightweight and corrosion-resistant, it is often used in occasions with weight requirements, and the price is relatively high.

Small Belt Conveyor Price Advantage

Mobile mini belt conveyors are small in size and lightweight, facilitating rapid transport and deployment, and are suitable for scenarios involving multiple work sites or frequent job relocations. They are also simple to operate, easy to install, and have low maintenance costs. Inclined mini belt conveyors can smoothly transport materials from lower to higher levels, making them suitable for scenarios in factories, warehouses, or production lines requiring multi-level transport. They offer high conveying efficiency, strong load-bearing capacity, reduced secondary handling and labor costs, improved production efficiency, and high cost-effectiveness.

Small Belt Conveyor Price Solution

For indoor applications, small belt conveyors can be equipped with lightweight or stainless steel frames, open or baffled synchronous or AC geared motors, standard control cabinets, and anchor mounting. Waterproofing and heating are generally omitted. For outdoor applications, corrosion-resistant stainless steel or treated structures are preferred, along with rain covers and protective covers, windproof anchoring, and grounding. Depending on the configuration and material, a basic lightweight unit (short-length, ordinary carbon steel) costs approximately $400–$1,200; a mid-range food-grade/stainless steel unit costs approximately $1,200–$27,000; and outdoor protection or additional heating and special controls cost approximately $2,000–$5,000.

Small Belt Conveyor Video

Small Belt Conveyor Price is the result of the combined effect of many factors. The price difference is mainly reflected in size, material, function and configuration. To select a suitable conveyor, the user needs to weigh the actual material conveying needs, site space limitations, and equipment operation requirements. For example, the conveying length, material characteristics, environmental conditions, and whether the mobile or climbing function is required should be considered.