Rice Bucket Elevator

The price of Rice bucket elevator varies from USD 300 to USD 8,000, depending on the type, material, lifting height, conveying capacity, etc.

Frequency (HZ): 50HZ, 60HZ

Voltage: 220V, 380V, 440V, 480V

Capacity: 10 ~ 160 T/h

Dimensions (L×W×H): 550mm * 360mm * 8500mm/customized

Belt speed: 1.6m/s

Frame material: stainless steel/alloy

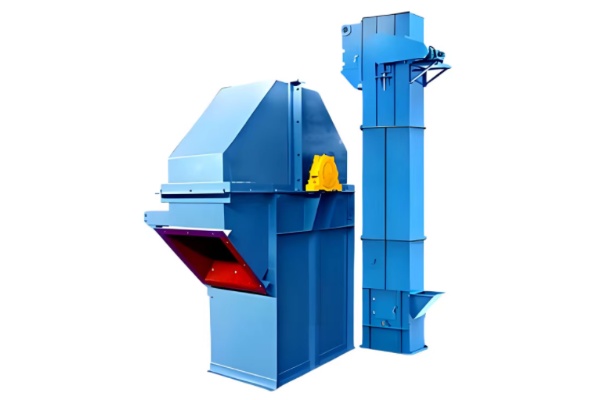

What is Rice Bucket Elevator?

Rice Bucket Elevator is mainly used to lift various bulk materials from low to high. According to different driving and carrying methods, Rice Bucket Elevator can be mainly divided into chain type, chain plate type and belt type. Chain and chain plate type elevators are generally suitable for conveying blocky and abrasive materials, while belt type elevators are more commonly used for conveying powdery and small granular materials. The output that Rice Bucket Elevator can achieve ranges from several tons to hundreds of tons per hour, and the lifting height can reach tens of meters or even higher, depending on the equipment model, bucket capacity, operating speed and material characteristics.

The correct selection of Rice Bucket Elevator is essential to ensure the stability and adaptability of material transportation. Rice Bucket Elevator is mainly divided into chain type, chain plate type and belt type, each type has its specific application scenarios and advantages. Chain elevators usually adopt single chain or double chain configuration, which is characterized by a sturdy structure. A plate-type elevator is similar to a chain type, but its load-bearing components are plates rather than individual chains, which makes it advantageous when conveying bulky, irregularly shaped, and breakage-sensitive materials. Belt-type elevators are favored for their smooth operation and low noise. When selecting a model, it is necessary to comprehensively consider multiple factors such as material characteristics, lifting height and conveying capacity, working environment, and operating continuity to ensure that the equipment can meet actual production needs.

What are the types of Rice Bucket Elevator?

Rice Bucket Elevator is mainly divided into three types: chain type, chain plate type and belt type. They differ in material conveying capacity and scope of application.

Chain Type Rice Bucket ElevatorProduction: The chain type elevator has a wide range of production, usually reaching tens to hundreds of tons per hour. The specific production depends on factors such as chain speed, hopper capacity and material density.

Lifting height: This type of elevator can achieve a large lifting height, usually reaching tens or even hundreds of meters. The strength and tensile strength of its chain make it stable in high-lift transportation.

Chain Plate Type Rice Bucket ElevatorProduction: The chain plate type elevator has a similar production to the chain type, which can also reach tens to hundreds of tons per hour. Because the chain plate provides a larger contact area, it can more stably convey large particles in some cases.

Lifting height: The chain plate type elevator can usually reach tens of meters in height, similar to the chain type, and is suitable for scenes requiring high-lift transportation.

Belt Rice Bucket ElevatorProduction: The production of belt elevators can range from a few tons to hundreds of tons per hour, depending on the belt width, line speed, and hopper spacing. Its high line speed enables high conveying efficiency when conveying light materials such as grains and flour.

Lifting height: The lifting height of this type of elevator is usually in the range of tens of meters, suitable for medium-height vertical conveying. Although its lifting height is not as high as that of the chain type, it is sufficient for most conventional material lifting needs.

Basic parameters of Rice Bucket Elevator

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

| Model | DTG20/15 | DTG26/13 | DTG26/18 | DTG26/23 | DTG36/28 |

| Capacity | 4-7 T/H | 5-8 T/H | 10-15 T/H | 15-20 T/H | 30-40 T/H |

| Power(kw) | 0.75-1.1 | 1.1 | 2.2-3 | 3-5.5 | 3-5.5 |

| Standard Height(m) | 5 | 5.3 | 5.3 | 5.3 | 5.3 |

| Line Speed(m/s) | 1.3-2.5 | 1.3-2.5 | 1.3-2.5 | 1.3-2.5 | 1.3-2.5 |

| Bucket Model | 1511 | 1511 | 1812 | 2314 | 2816 |

What are the advantages of Rice Bucket Elevator?

Rice Bucket Elevator, as a vertical conveying equipment, has many advantages. It not only performs well in reducing the material breakage rate, but also ensures stable vertical conveying capacity, demonstrates wide material adaptability and high reliability, and is also very convenient in operation and maintenance.

Low breakage rate: Through stable belt traction and optimized hopper design, the impact and friction of grains during transportation are minimized to the greatest extent, thereby significantly reducing the rice breakage rate and ensuring product integrity and quality.

Stable vertical transportation capacity: Rice Bucket Elevator saves a lot of floor space and can lift grains to a higher height to meet the needs of high-level warehousing. It realizes continuous and stable material transportation, facilitates seamless connection with front-end and back-end equipment, and supports automated production.

Strong material adaptability and reliability: The equipment is widely used in a variety of granular, powdered grains and similar materials, and often uses polymer material hoppers, which have the advantages of wear resistance and non-stickiness. Its structure is mature, its operation is stable and reliable, and with perfect safety protection devices, the equipment has a low failure rate and can operate stably for a long time.

Easy operation and maintenance: Rice Bucket Elevator is simple to operate and easy for personnel to master. At the same time, the equipment is equipped with inspection doors and cleaning ports, making daily inspection, adjustment and removal of accumulated materials relatively convenient.

What are the applications of Rice Bucket Elevator?

The application scenarios of Rice Bucket Elevator mainly revolve around the reception, cleaning, processing, storage and transportation of bulk grains, covering multiple steps from the field to the table. The following are the specific application scenarios of Rice Bucket Elevator:

Grain reception and warehousing: It is used to lift the arriving raw grain from a low position to a high-level cleaning equipment or pre-treatment warehouse, which is the first step for grain to enter the processing and storage process.

Material transfer in the grain cleaning link: On the grain cleaning production line, Rice Bucket Elevator is responsible for lifting grains at different processing stages to the next level of cleaning or selection equipment to ensure the continuity of the cleaning process.

Connection in the rice processing (rice milling) process: In the rice mill, it acts as a key conveying tool between different processing units, lifting semi-finished grains from lower equipment to higher-level subsequent processing equipment.

Circulation and lifting in grain drying system: Rice Bucket Elevator is used to realize the vertical circulation of materials in the drying tower, or to lift them again to other processing equipment after taking them out from the bottom of the drying tower.

High-level storage and outbound storage: It is a key equipment to lift processed or stored grain to the top of large silos for storage, and it can also lift grain again to the loading or packaging link when outbound.

What is the price of Rice Bucket Elevator?

The price of Rice Bucket Elevator is affected by many factors. It is not a standardized commodity, but a device that needs to be customized or selected according to specific needs. The following are the main factors affecting the price of Rice Bucket Elevator:

Type: Belt elevators are usually relatively low-priced under the same specifications. Chain and chain plate elevators will increase their prices accordingly due to their stronger structure and higher material costs.

Material: Carbon steel is a more common material with relatively low cost. Stainless steel (such as food grade or corrosion resistance requirements) will significantly increase the cost. The hopper of polymer material will also affect the price.

Specification parameters: The higher the lifting height, the greater the required chain/belt length, frame height, and motor power, the higher the cost. Conveying capacity (output), the greater the required output, means that a larger hopper, wider belt/chain plate, faster running speed, and a stronger drive system are required, which will push up the price.

Bucket size and quantity: The larger the hopper and the greater the quantity, the higher the cost.

Drive system: Higher-power motors and motors and reducers from well-known brands will cost more. The frequency converter can achieve speed regulation and soft start, but it will add additional costs.

How to buy Rice Bucket Elevator?

When choosing Rice Bucket Elevator, you need to comprehensively balance material characteristics, transportation requirements, environmental conditions and other factors according to the specific needs of the project to select the appropriate lifting equipment.

Particle size: Powdered and small granular materials (such as flour, cement, fine sand): usually suitable for belt elevators because they run smoothly and have little impact on the materials.

Large particles and block materials (such as coal, ore, gravel): require higher structural strength and wear resistance, chain or chain plate elevators are more suitable, and can withstand greater impact and load.

Abrasion: Strong abrasive materials: chains or chain plates should be used, and wear-resistant materials (such as manganese steel, wear-resistant alloys) for hoppers and liners should be considered.

High-temperature materials (such as clinker, high-temperature slag): chains, chain plates, hoppers and seals made of high-temperature resistant materials must be selected. Belt elevators are usually not suitable for high-temperature materials.

Humidity and stickiness: Wet or sticky materials tend to adhere to the inner wall of the hopper or the discharge port, resulting in incomplete discharge or blockage. Specially designed hopper shapes, anti-stick linings or vibration devices, and structures that can effectively scrape the materials may be required.

Corrosiveness: Corrosive materials (such as certain chemical raw materials) need to use corrosion-resistant materials, such as stainless steel or special coatings, to prevent equipment from corrosion and extend service life.

The design of Rice Bucket Elevator is to provide a mechanical method for conveying grain crops from low to high positions. Its operation process focuses on ensuring the continuous upward movement of materials to meet the needs of subsequent processes or storage. Rice Bucket Elevator usually has a fully enclosed shell to help manage dust and keep the material clean. Its belt traction system and specially designed hopper are designed to exert less force on grain particles to maintain the integrity of the material.