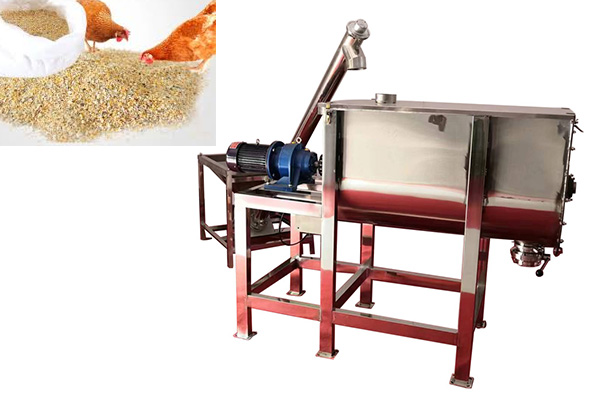

Chicken feed mixer price

Wednesday September-17 2025 16:21:08

Chicken feed mixer price is not fixed. Its price is usually determined by the model, capacity, material, degree of automation and configuration. The price usually ranges from $400 to $6500, which directly reflects the mixing volume and configuration of different models of mixers. A household mixer with a 50 kg batch capacity costs significantly less than a large-scale farm mixer equipped with an intelligent control system capable of mixing 1,000 kg per batch. This is because larger equipment requires a more robust structure, a larger drive motor, and more sophisticated control systems and manufacturing processes.

When selecting a chicken feed mixer, price isn't the only factor; consider your specific needs. First, clarify your production requirements: The material characteristics you need to mix (e.g., powder, granules, whether liquid is added, moisture content, temperature) directly determine the appropriate material (e.g., carbon steel or stainless steel) and mixing device type (ribbons, paddles). Your batch capacity (kg/time) is a key factor in selecting the equipment's capacity, size, and power. Choose the right product based on these key parameters.

Chicken feed mixer price

| Mixer type | Structural features and uses | Processing capacity (per batch) | Applicable objects | Reference price range (USD) |

| Vertical mixer | Vertical structure, relying on spiral lifting and material circulation mixing, simple structure, low cost | 200kg~1000kg | Small breeders, individual farms | $200~$900 |

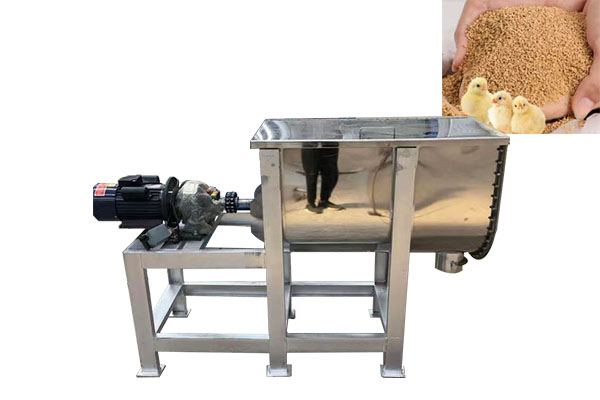

| Horizontal mixer | Horizontal cylinder, equipped with spiral ribbon or blade mixing, high mixing uniformity | 300kg~2000kg | Small and medium-sized farms | $400~$2,500 |

| Screw ribbon mixer | Inner and outer screw ribbon structure, reverse rotation to push materials, high mixing efficiency, suitable for powder + granular feed | 500kg~3000kg | Feed processing households, cooperatives | $1,200~$4,500 |

| Double-shaft paddle mixer | Two shafts with paddles turn synchronously, fast mixing speed, excellent uniformity, suitable for efficient batching system | 1 ton~5 tons | Medium and large breeding enterprises, feed factories | $3,000~$12,000 |

How to choose the appropriate model according to Chicken feed mixer price?

When selecting a chicken feed mixer based on price, consider the daily mixing volume of feed ingredients, the mixing requirements (whether liquids are added, cooling or heating is required), and the material used.

Regarding material selection, ordinary carbon steel (Q235) is the most economical choice. However, for materials that require the addition of liquids or food-grade or pharmaceutical-grade materials, stainless steel (such as 304 or 316L) is required, which can be twice or even more expensive than carbon steel equipment. Regarding the scale of production, for daily mixing volumes less than 1 ton, a vertical or small horizontal mixer can be selected. For daily mixing volumes between 1 and 5 tons, a ribbon horizontal mixer is recommended. For large farms or feed mills, a twin-shaft paddle mixer is recommended. Of course, the larger the mixing volume, the larger the model, and the more expensive it will be. The single mixing volume ranges from 100 kg to 8,000 kg, and the mixing time is 5-20 minutes. The capacity can be customized according to needs. For some applications that require precise temperature control and intelligent data recording, the equipment needs to be specially designed, which will also increase the equipment cost.

Chicken feed mixer purchasing advice

Once you have a rough idea of chicken feed mixer prices, consider the following steps based on your budget. First, don't just look at one supplier; contact several to compare their product specifications, quality, performance, price, after-sales service, and customer reviews. Then, when contacting suppliers, be sure to explain your needs in detail. For example, how much feed do you need to mix daily (tons/hour or kilograms/batch)? What type of feed do you primarily mix (powdered, granular, or with liquid?)