Rotary Premade Bag Packing Machine For Powder

Rotary Premade Bag Packing Machine For Powder Common bag types include three-side seal bags, four-side seal bags, stand-up bags, zipper bags, etc. The output is generally 30-60 bags/minute. The price is about US$5,000 to US$30,000.

Packaging bag type: pre-made zipper bag

Packing speed: 15-50 bags/minute

Filling system: screw metering machine

Machine structure: rotating eight-station

What is Rotary Premade Bag Packing Machine For Powder?

Rotary Premade Bag Packing Machine For Powder is used for automatic packaging of powder materials such as milk powder, coffee powder, seasoning powder, etc. The equipment adopts a rotary structure to automatically complete the processes of bag opening, metering, filling, sealing, etc., and cooperates with the spiral weighing system for accurate metering. Common models include RZ8-200 and RZ6-160, which are suitable for a variety of bag types and production requirements, and the speed is generally 30-60 bags/minute. The machine has the characteristics of fast and stable operation, easy operation and convenient maintenance. It is made of food-grade stainless steel, meets hygiene standards, and ensures a clean and safe packaging process. The price is about US$5,000 to US$30,000 depending on the configuration, which is suitable for medium and large enterprises to improve packaging efficiency and automation level.

What are the main advantages of Rotary Premade Bag Packing Machine For Powder?

Rotary Premade Bag Packing Machine For Powder has many advantages, such as a wide variety of bag types, small footprint, and accurate metering, as follows:

The rotary station design is adopted, which is more efficient and occupies a smaller area, and is particularly suitable for medium and high-volume continuous operations.

Equipped with a servo-driven screw metering system, it has accurate metering and is suitable for powder materials with poor fluidity and easy dust.

Adopting PLC control system and human-machine interface touch screen, the parameters are convenient to adjust, the operation is simple, and it has an automatic fault alarm function.

Compatible with a variety of prefabricated bag types, such as self-supporting bags, zipper bags, flat bags, etc., the packaging forms are diversified, and the added value of the products is increased.

Equipped with safety protection devices, such as no filling without bag, no cutting without sealing, and door opening shutdown, etc., effectively ensure the safety of operation.

Parameters of Rotary Premade Bag Packing Machine For Powder

The packaging speed of Rotary Premade Bag Packing Machine For Powder is generally 30-60 bags/minute depending on the material and bag type. It is suitable for prefabricated bags such as self-supporting bags and zipper bags. The detailed technical parameters are as follows:

| Parameter | Specification/Description |

| Packaging Speed | 30-60 bags/min (varies by material and bag type) |

| Applicable Bag Types | Stand-up pouches, flat pouches, zipper bags, and other pre-made bags |

| Bag Width Range | 100-200mm |

| Bag Length Range | 150-300mm |

| Measuring Method | Screw feeder (optional servo control system) |

| Filling Accuracy | ±1-2% |

| Power Requirement | AC380V, 3-phase 5-wire, 50Hz |

| Air Consumption | 0.6m³/min (6kg/cm²) |

| Machine Material | Food-grade 304 stainless steel |

| Control System | PLC + touch screen, supports multi-language interface |

| Dimensions | Approx. 1700mm × 1500mm × 1650mm |

| Weight | Approx. 1200kg |

Packing bag types of Rotary Premade Bag Packing Machine For Powder

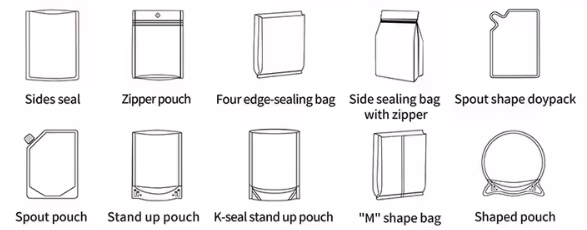

Rotary Premade Bag Packing Machine For Powder is suitable for a variety of powder packaging bag types. Common bag types include three-side sealed bags, four-side sealed bags, self-supporting bags, zipper bags, and bags with handles; optional zippers, hanging holes, European grooves, handles and other functions:

Packing bag types

Three-side sealed bags: use multi-layer composite films (such as PET/AL/PE or OPP/VMPET/PE), with good barrier and sealing properties, suitable for moisture-proof and anti-oxidation powders (such as milk powder, seasonings).

Four-side sealed bags: The structure is more stable, usually using PE or CPP film, suitable for high-flowability powders (such as starch, chemical powder).

Self-supporting bag: with support structure at the bottom, the material is mostly PET/PE composite film, which can be placed upright and is suitable for retail packaging (such as protein powder, coffee).

Zipper bag: built-in zipper at the seal, commonly used PE or KPET materials, can be repeatedly sealed (such as health products, granules).

Handle bag: reinforced PE or woven composite materials are used for easy handling (such as large package feed, building material powder).

Function of packaging bag

Anti-static function: by adding anti-static coating, it is suitable for powders that are susceptible to static electricity (such as milk powder, chemical powder).

Vacuum/nitrogen filling function: using high barrier materials, it can be vacuumed or filled with nitrogen to extend the shelf life of food or pharmaceutical powder.

Easy tear design: the bag mouth is preset with incisions or serrations, which is convenient for users to open quickly.

Hanging hole: the top is preset with a hanging hole, which is suitable for hanging display on supermarket shelves (such as small package seasonings).

European slot: the bag mouth is designed with a European slot, which is convenient for automatic filling and machine grabbing to improve packaging efficiency.

Handle: Thickened handle design facilitates the handling of large-volume powder (such as 5kg-25kg).

Tear groove (easy tear): Preset V-shaped or linear tear for consumers to open quickly.

Zipper (re-seal): Built-in plastic or metal zipper, suitable for products that need to be taken multiple times (such as milk powder, protein powder).

Rotary Premade Bag Packing Machine For Powder Solution

Rotary Premade Bag Packing Machine For Powder is suitable for many industries such as food, chemical, pharmaceutical, and agriculture. Its advantages include high-precision metering, high-speed packaging, excellent sealing, and flexible customization functions (such as vacuuming, nitrogen filling, etc.), which can meet the packaging needs of different powders.

Food industry

Seasoning powder (such as chicken essence, chili powder, curry powder): Moisture-proof and anti-oxidation packaging materials are used to ensure lasting flavor.

Milk powder/protein powder: Nitrogen-filled fresh-keeping packaging to prevent agglomeration and extend shelf life.

Instant beverages (coffee, milk tea powder): Accurate metering to avoid waste and improve filling efficiency.

Flour/starch: dust-proof and sealed packaging, in line with food safety standards.

Chemical and building materials industry

Paint powder: anti-dust design, reduce pollution, and improve packaging sealing.

Cement additives: wear-resistant packaging, suitable for high-intensity industrial transportation.

PVC/plastic powder: anti-static treatment to avoid powder adsorption affecting packaging accuracy.

Dye/pigment powder: moisture-proof and light-proof packaging to ensure color stability.

Pharmaceutical and health care products industry

Chinese medicine powder: meet GMP standards to avoid cross contamination.

Nutrient powder (vitamin, probiotics): aluminum foil composite film packaging, moisture-proof and light-proof.

Pharmaceutical excipients (such as lactose, microcrystalline cellulose): high cleanliness packaging to ensure drug safety.

Agriculture and feed industry

Pesticide powder: leak-proof and corrosion-resistant packaging to ensure transportation safety.

Feed additives: precise ratio packaging to improve mixing uniformity.

Seed coating agent: moisture-proof and sealed to ensure the stability of active ingredients.

What is the price range of Rotary Premade Bag Packing Machine For Powder?

The price range and corresponding specific models of Rotary Premade Bag Packing Machine For Powder are as follows:

The entry-level model RZ4-100 Rotary Premade Bag Packing Machine For Powder is suitable for small batch production and small enterprises, with a packaging output of about 20-30 bags/minute, and a price range of about US$5,300 to US$12,000.

The mid-range model RZ6-160 Rotary Premade Bag Packing Machine For Powder has a packaging output of about 30-50 bags/minute, equipped with a PLC control system and high-precision spiral metering, and a price range of about US$12,000 to US$30,000, which is suitable for medium-sized production lines.

The high-end model RZ8-200 Rotary Premade Bag Packing Machine For Powder has a packaging output of more than 50 bags/minute, adopts a servo drive system, realizes fully automated operation, is compatible with a variety of bag types and has complete safety protection functions, and the price range is about US$30,000 to US$42,300 or more, which is suitable for large-scale rapid production needs.

Manufacturers of Rotary Premade Bag Packing Machine For Powder

The main manufacturers of Rotary Premade Bag Packing Machine For Powder are concentrated in Xinxiang, Henan, Ningbo, Zhejiang, Suzhou, Jiangsu, and other places in China. There are also manufacturers in Europe, the United States, and India. Our factory relies on rich experience, customization capabilities, automatic control, and high-quality stainless steel materials to ensure stable and fast equipment. The main models are DH-RPB-150, DH-RPB-250, and DH-RPB-350, with a packaging speed of 30-100 bags/minute, a bag width of 80-350mm, a metering range of 10-3000g, and equipped with a PLC touch screen, suitable for a variety of powder packaging.

Related news

- Fully Automatic Small Bag Powder Packaging Machine

- What are the packaging bag formats for Powder Packaging Machine?

- Ton Bag Feeding Station Process Flow

- Fully automatic bagging packaging machine price

- Fully automatic unloading packaging machine price

- Vertical Form Fill Seal Packing Machines Suppliers