Double roller corn crusher

Saturday January-31 2026 15:35:34

Double roller corn crusher is used to crush whole corn into small particles with a size between 0.5-10mm. They reduce the volume of the corn through compression, shearing, and grinding operations using two parallel, counter-rotating rollers, achieving the desired particle size. The crushing process is gentle, produces uniform particle size, and minimizes excessive starch loss. Crushing capacities range from 1 ton per hour for small models to 25 tons per hour for large models. Depending on the intended use and requirements, both smooth and toothed roller surfaces are available.

What types of double roller corn crushers are there?

There are two types of double roller corn crushers: smooth rollers and toothed rollers. Their shapes and structures differ, as do their crushing effects and output.

Smooth Roller Double Roller Corn Crusher: Also called a double roller crusher, this type has smooth, toothless rollers. It crushes corn using the compressive force generated by the relative rotation of two parallel smooth rollers. The crushed corn is in small particle size with less fine powder, preserving the endosperm structure relatively well. The output particle size is 1-10mm, and the crushing capacity is 3-15 tons per hour. It can be used to crush hard, plump, dry corn.

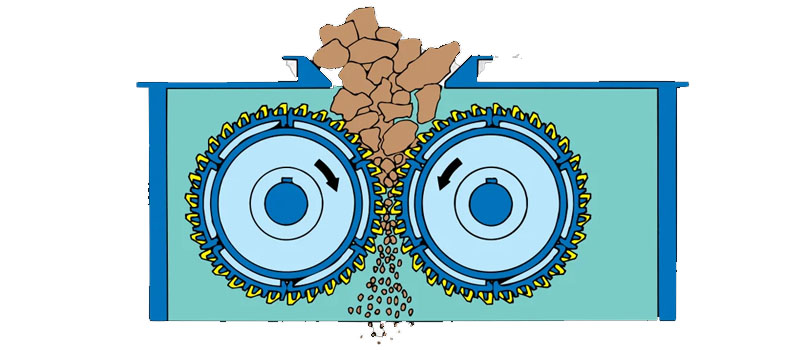

Toothed Roller Double Roller Corn Crusher: This type crushes corn using the shearing and impact force generated by the interlocking rotation of two toothed rollers. The teeth come in different specifications, such as sharp teeth and blunt teeth. It can crush corn more thoroughly and quickly break down corn ears. However, if the teeth are too sharp, it can produce more fine powder. The output particle size is 0.5-8mm, and the crushing capacity is 5-25 tons per hour. It can be used to crush wet corn, corn with the cob intact, or corn with many impurities.

What are the advantages of a double roller corn crusher?

A double roller corn crusher uses the extrusion and shearing force generated by the counter-rotating of two rollers to crush corn. The crushed corn particles are uniform in size and intact, ensuring consistent particle size without over-grinding. This gentle crushing method minimizes nutrient loss. The output particle size can be controlled within 10mm, and different particle sizes, from coarse to fine, can be controlled by adjusting the roller gap, making it suitable for various industries such as feed processing and brewing raw materials. The crushing capacity can reach 25 tons per hour. Roller diameter, rotation speed, and feeding/discharging methods can be customized according to application scenarios and capacity requirements. Custom roller surface textures, such as smooth rollers, toothed rollers, and grooved surfaces, can be selected based on different corn varieties.

How does a double roller corn crusher work?

When a double roller corn crusher is working, corn is fed into the equipment through the inlet. Two rollers rotating at 200-500 rpm exert extrusion and shearing forces to crush and shear the whole corn into the required particle size. The particle size of the finished product is controlled by adjusting the distance between the two rollers. The crushed corn falls onto a screen below. Qualified fine material passes directly through the screen and is discharged from the outlet, while unqualified coarse material is screened out.

Double Roller Corn Crusher Parameters

| Model (Diameter-Length) | Capacity (kg/hour) | Power (kW) |

| 120-180 | 1500 | 2.2-3.0 |

| 140-300 | 3000 | 3.0-5.5 |

| 170-500 | 5000 | 7.5-11 |

What are the structural components of a double roller corn crusher?

A double roller corn crusher mainly consists of an integrally supported frame, a pair of parallel crushing rollers for crushing corn, an adjustment mechanism for controlling the particle size of the crushed corn, a feed hopper, a guide plate, a transmission system including a motor, pulleys, and reduction gears, a discharge port, a protective cover, bearing seats, a lubrication device, and fasteners.

What are the applications of a double roller corn crusher?

A double roller corn crusher is mainly used in feed processing and livestock farms to crush corn raw materials into particle sizes suitable for subsequent mixing and pelleting. It can also be used in industries such as wineries, starch plants, grain processing plants, and small and medium-sized workshops. It can crush dry corn, wet corn with a moisture content of 15%-25%, corn on the cob, corn cobs, and corn stalks into small particles of 1-10mm, directly providing raw materials for subsequent crushing, fermentation, and pelleting processes.

Chinese Herb Grinder Machine

Chinese Herb Grinder Machine Seeds Coarse Crusher

Seeds Coarse Crusher