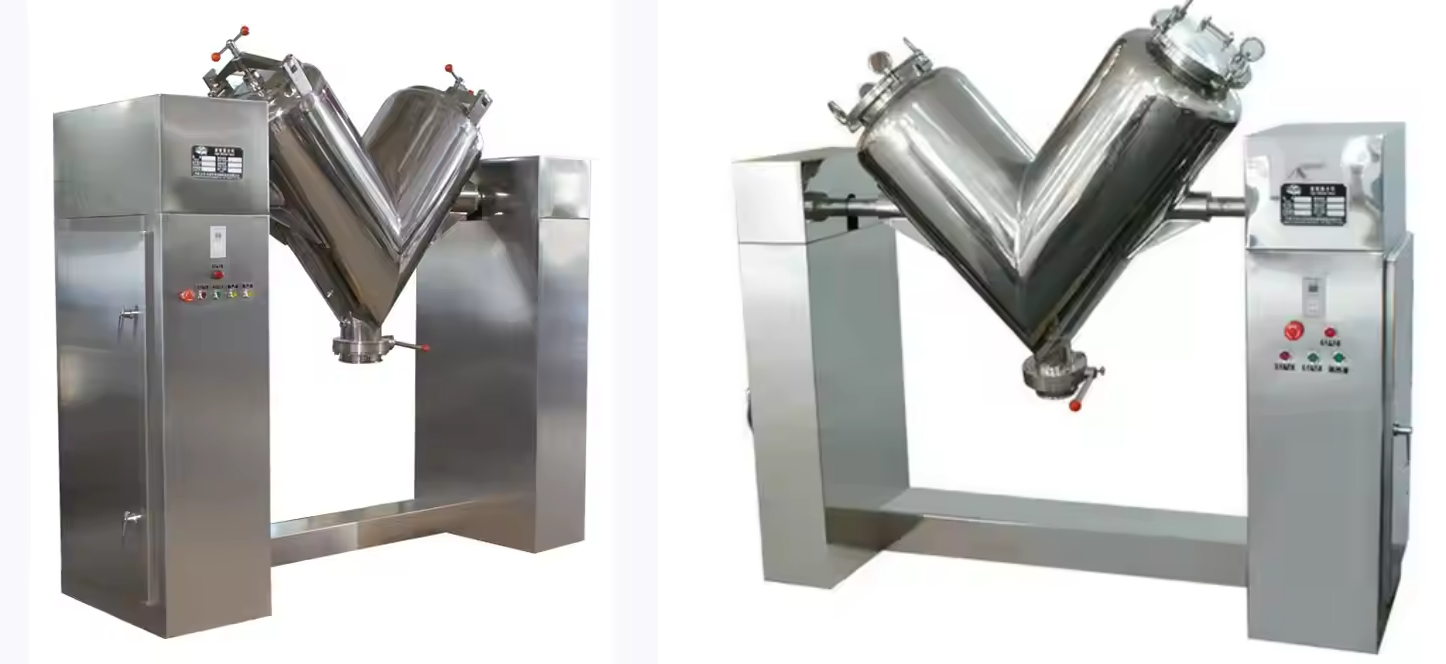

V-type powder mixer

Using the unique V-shaped tank body to rotate, the materials are repeatedly separated and merged to achieve a highly uniform mixing effect

Capacity: 50L, 100L, 200L, 300L, etc.

Material: stainless steel (such as 304, 316L) or carbon steel

Mixing speed: between 10-30RPM

Power: 0.75kW-5.5kW

Product description

V-type powder mixer is an efficient and gentle mixing equipment designed for handling dry powder and granular materials. Such materials usually have a certain degree of fluidity, but may also have large density differences, be fragile, or have extremely high requirements for mixing uniformity. The V-type mixer rotates around the horizontal axis through its unique V-shaped tank body, so that the powder inside is continuously separated, merged and diffused under the action of gravity.

The mixing uniformity can reach more than 99%, and the processing process is gentle, without mechanical extrusion, which can effectively protect the integrity of fragile particles (such as crystals) or water-containing materials.

Applicable materials

Due to its structural characteristics and mixing principle, the V-type powder mixer has good applicability to various types of powders: powders/particles with good fluidity, powders and particles with small differences in physical properties, materials that are easily broken or easily worn, or materials that contain a small amount of moisture or viscosity.

Chemical powders (such as alumina, silica), food additives (such as seasoning powder, milk powder), pharmaceutical intermediates, ceramic powders, metal powders, plastic additives, etc.

What is the difference between v-type powder mixer and double cone blender?

|

Comparison items |

V-type powder mixer |

Double cone mixer (mixer) |

|

Pictures |

|

|

|

Appearance structure |

"V"-shaped cylinder, composed of two symmetrical tubes |

Two cones are connected to form a cone, and the appearance is double cone |

|

Working principle |

Gravity diffusion mixing, material turning is achieved by cylinder rotation |

Also gravity diffusion mixing, cylinder rotation mixing |

|

Mixing uniformity |

High (applicable to powders with similar particle size and density) |

High (applicable to materials with different particle sizes and density differences) |

|

Loading factor |

The loading factor is about 40% of the total volume |

The loading factor can reach about 50% of the total volume |

|

Applicable material types |

Powders with good fluidity and uniform particle size |

Various types of powders or particles, density differences are also applicable |

How does the V-type powder mixer work

The V-type powder mixer mainly achieves material mixing by rotating and turning its V-shaped mixing barrel. The specific working principle is as follows:

V-type structure: The mixing barrel is composed of two cylindrical containers connected in a V shape. When the mixing barrel rotates around its horizontal axis, the material continuously flows from one end to the other in the V-shaped barrel, forming repeated separation and combination.

Three-dimensional movement: As the V-shaped mixing barrel rotates, the material simultaneously performs three-dimensional movement in the barrel in the circumferential, radial and axial directions. This complex movement mode enables materials of different components to fully flow, diffuse, accumulate and blend with each other.

Diffusion mixing: The V-type mixer mainly relies on the diffusion mixing mechanism to achieve the mixing effect through the free flow and random movement of material particles. For powdery or granular materials with good fluidity, its mixing efficiency is high.

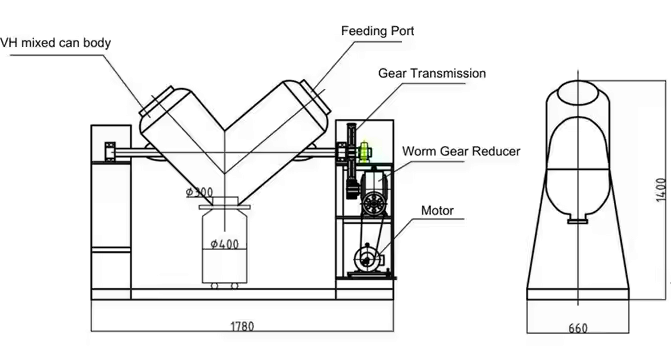

Structural composition of V-type powder mixer

V-shaped barrel: It consists of two asymmetric barrels, generally made of stainless steel, with polished inner and outer walls, beautiful appearance, corrosion resistance, easy to clean, and can effectively avoid material residue and cross contamination.

Power transmission system: It includes motors, reducers, belts and couplings, etc., which provide power for the rotation of the V-shaped barrel, and the rotation speed can be controlled by the reducer to meet the mixing needs of different materials.

Feeding and discharging device: Usually it can be equipped with a vacuum feeding device to achieve dust-free feeding. The discharge port is generally equipped with a butterfly valve or a rotary valve to facilitate the control of the discharge speed and flow rate, and to ensure smooth discharge without residue.

What are the disadvantages of the V-type powder mixer?

Low loading coefficient: In order to ensure the mixing space and effect, the loading capacity of the V-type mixer is generally about 40% of the total volume of the cylinder, which is less efficient than other forced stirring mixers (such as double-screw ribbon mixers) and has limited production capacity in mass production.

Discharge residue problem: Although the overall residue is small, there may still be dead corners or a small amount of residue at the connection of the V-type cylinder and the bottom discharge port, especially for lightweight powders with low specific gravity and easy to float. Improper cleaning can easily cause material waste or cross contamination.

Mixing efficiency is limited by material characteristics: The V-type mixer relies on the gravity flipping of the cylinder to achieve diffusion mixing. For materials with large particle size differences, large specific gravity differences, or easy to absorb moisture and agglomerate, the mixing effect may not be ideal, and stratification or agglomeration is prone to occur.

No forced stirring device: The equipment usually does not have a built-in stirring paddle or crushing device, so it is not suitable for agglomerated materials and mixtures that need to be sheared, and cannot be used for wet mixing, heating, spraying and other composite treatments.

Technical parameters of V-type powder mixer

|

Model |

Total volume (L) |

Loading capacity (kg) |

Drum speed (rpm) |

Power (kW) |

Equipment weight (kg) |

|

V-50 |

50 |

20 |

12 |

0.55 |

100 |

|

V-200 |

200 |

80 |

12 |

1.5 |

300 |

|

V-500 |

500 |

200 |

10 |

2.2 |

600 |

|

V-1000 |

1000 |

400 |

8 |

4 |

1200 |

Note: The loading capacity is generally about 40% of the total volume to facilitate the mixing effect.

What is the purpose of v-type powder mixer

The V-type powder mixer is mainly used to mix dry powder or granular materials efficiently and gently. Its unique V-shaped design and no dead angle characteristics make it perform well in a variety of scenarios with strict requirements on mixing uniformity and material integrity.

In the pharmaceutical industry, it is often used to mix Chinese and Western medicine powders and granules, such as evenly mixing multiple active pharmaceutical ingredients and excipients to prepare precursors for tablets, capsules or granules to ensure accurate dosage and consistent efficacy of each tablet. In the food industry, V-type mixers are used to mix various condiments (such as chicken essence, spices), food additives (such as nutritional enhancers, pigments), coffee powder, milk powder and cereal premixes, etc., to ensure the uniformity of product taste and quality.

In the chemical industry, it can efficiently mix plastic particles, pigments, dyes, fine chemical raw materials and fertilizers, etc., to ensure the stability of product performance, such as mixing plastic particles of different colors to produce plastic products of specific colors, or mixing pesticide raw materials and carriers to prepare pesticide formulations. In addition, in the feed industry, V-type mixers are used to mix various animal feeds, premixes and nutritional additives to ensure that animals get balanced nutrition and promote healthy growth; in metallurgy, ceramics and scientific research, it is also often used to mix metal powders, ceramic raw materials or small batch samples in the laboratory to meet the requirements of precision formulas.

What is the mixing efficiency of the V-type powder mixer?

The mixing efficiency of the V-type powder mixer is outstanding, mainly reflected in the fast mixing speed, high uniformity and low energy consumption, as follows:

Structural design optimization: The asymmetric structure of the V-type cylinder makes the material produce a unique "shear-diffusion-superposition" movement when it rotates. When the cylinder rotates, the material is continuously lifted, thrown and cross-flowed in the cylinders on both sides, forming a strong convection mixing effect. For example, for powders with good fluidity, it usually takes only 5-15 minutes to complete the mixing, which is much less than the time consumed by traditional trough mixers and other equipment.

The uniformity can reach more than 99%: through the continuous rotation of the cylinder, the material is repeatedly divided, merged and superimposed, and the spatial position of each particle is constantly updated, and finally a highly uniform mixing state is achieved.

Reduce material separation: During the mixing process, the movement of the material is mainly overall convection rather than violent stirring and shearing, so it is not easy to cause stratification due to differences in particle size or density. It is especially suitable for mixing powders with small differences in physical properties (such as materials with similar particle size and density).

Application scenario examples

In the food industry, V-type powder mixers are often used to mix ingredients for seasoning powder, milk powder, protein powder and other products. Taking seasoning powder production as an example, different flavor powders, sugar, salt, flavor powder and other ingredients need to keep the particles intact and evenly distributed during the mixing process. The V-type mixer, with its gentle tumbling mixing method, does not generate too much heat or dust, and can ensure that the flavor and particle shape are not destroyed. In the pharmaceutical industry, the V-type mixer is also suitable for premixing and main mixing of non-sticky powders such as intermediates and drug powders, and is particularly suitable for small batch production under GMP requirements.