Cement Vacuum Loading Machine

Cement Vacuum Loading Machine is an automated device that utilizes vacuum to achieve closed-loop conveying of powdered and granular materials. It is primarily used in cement production for conveying raw materials, semi-finished products, and additives.

Belt Material: Stainless Steel

Voltage: 380V / Customizable

Application: Product Conveying

Frame Material: 304, 316 Stainless Steel/Carbon Steel

Conveying Capacity: 10 kg - 10 tons/hour

Length: Customizable, 1-100 meters

Conveyed Materials: Granular and Powdered Products

Applicable Materials: Cement clinker, fly ash, slag powder, gypsum powder, pozzolanic blends, mineral powder, limestone powder, coal powder

What is a Cement Vacuum Loading Machine?

Cement Vacuum Loading Machine can quickly process powdered and granular materials such as cement and fly ash, completely eliminating dust pollution issues associated with traditional conveying methods and meeting the stringent environmental and clean production requirements of modern cement production. The core of the equipment features a wear-resistant design and explosion-proof configuration, enabling long-distance conveying capabilities and stable continuous operation. It supports multiple uses and can be customized to meet the needs of the conveying site and production, meeting diverse conveying scenarios.

What are the advantages of the Cement Vacuum Loading Machine?

With its high speed, safety, and reliability, the Cement Vacuum Loading Machine perfectly solves the problems of high dust, high waste, and frequent maintenance associated with traditional conveying methods in the cement industry, making it an ideal choice for modern cement plants to improve quality and efficiency.

The price of a cement vacuum loading machine is influenced by a variety of factors, including material, specifications, configuration, brand, and production process.

Material: The material of components that come into contact with the material is a key factor. Carbon steel is relatively inexpensive and therefore relatively inexpensive. Stainless steel, especially corrosion-resistant 316L stainless steel, is significantly more expensive.

Specifications: Prices vary depending on equipment specifications and models, such as conveying capacity, lifting height, and conveying distance. Cement vacuum loaders with small throughput and short conveying distances are relatively inexpensive, while large, industrial-grade equipment with high throughput and long conveying distances is more expensive.

Configuration: The higher the configuration, the higher the price. For example, cement vacuum loaders equipped with specialized features such as advanced PLC control systems, CIP cleaning systems, SIP sterilization systems, and explosion-proof motors will cost significantly more than standard equipment.

Production Process: Manufacturers with advanced production processes can better ensure product precision, performance, and reliability during the manufacturing process, but this will increase production costs, which in turn affects the price.

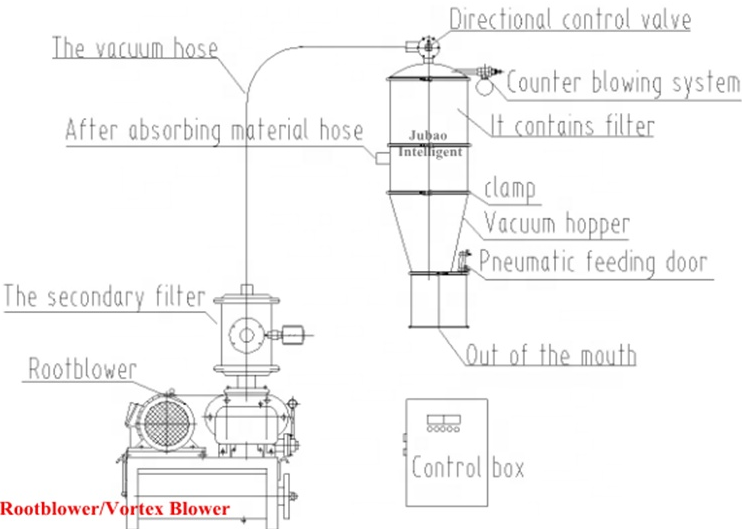

Cement Vacuum Loading Machine Components

The core of the Cement Vacuum Loading Machine consists of a vacuum pump for power, wear-resistant conveying piping, a cyclone separator for gas-solid separation, a pulse backflush filtration system, and a heavy-duty discharge valve to ensure complete discharge.

The vacuum power unit: Utilizing a Roots vacuum pump or liquid ring vacuum pump, it provides the required negative pressure, offering continuous operation and high reliability, making it the "heart" of the entire machine.

Wear-Resistant Conveying Pipeline: Special ceramic-lined pipes or bimetallic composite pipes ensure long service life in the highly abrasive cement conveying environment. Cyclone Separator: A primary separation device that utilizes centrifugal force to separate most of the material from the air, reducing the load on downstream filters.

Pulse Backflush Filtration System: Utilizing filter cartridges with oil- and water-resistant filter media, coupled with a compressed air pulse backflush mechanism, achieves efficient gas-solid separation and continuous self-cleaning.

Heavy-Duty Discharger: Equipped with a large pneumatic or electric discharge valve, this device ensures rapid and complete discharge of cement materials under positive pressure, leaving no residue.

Customizable Cement Vacuum Loading Machine Functions

Cement applications include finished product transportation in cement plants, mixing at construction sites, and building material processing. The Cement Vacuum Loading Machine offers flexible customization to meet the diverse needs of various scenarios.

Finished product transportation in cement plants: Suitable for continuous feeding at large production capacities. To meet the needs of cement plants transporting finished product silos to bulk cement trucks or packaging machines, a customized "multi-pipeline parallel conveying system" can be used. One vacuum pump drives two to four conveying pipelines, simultaneously feeding multiple target devices.

Construction site mixing: Suitable for mobile and flexible feeding. For construction sites requiring frequent equipment movement, a customized "mobile cement vacuum loader" can be used. This integrates the vacuum pump, separation hopper, and control system onto a steel structure with universal wheels. Weighing 500-800 kg, the machine can be quickly moved to different mixing locations by forklift or crane.

Building materials processing: Suitable for special cement transportation. For the transportation of special cement, a "low-loss conveying system" can be customized. Wear-resistant ceramic-lined pipes + high-precision discharge valves are used to control the material loss rate to below 0.5%. At the same time, the hopper and the inner wall of the pipe are treated with anti-static treatment to avoid the residue and loss of cement dust due to electrostatic adsorption.

Cement Vacuum Loading Machine Technical Parameters

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

Core Working Principle of the Cement Vacuum Loading Machine

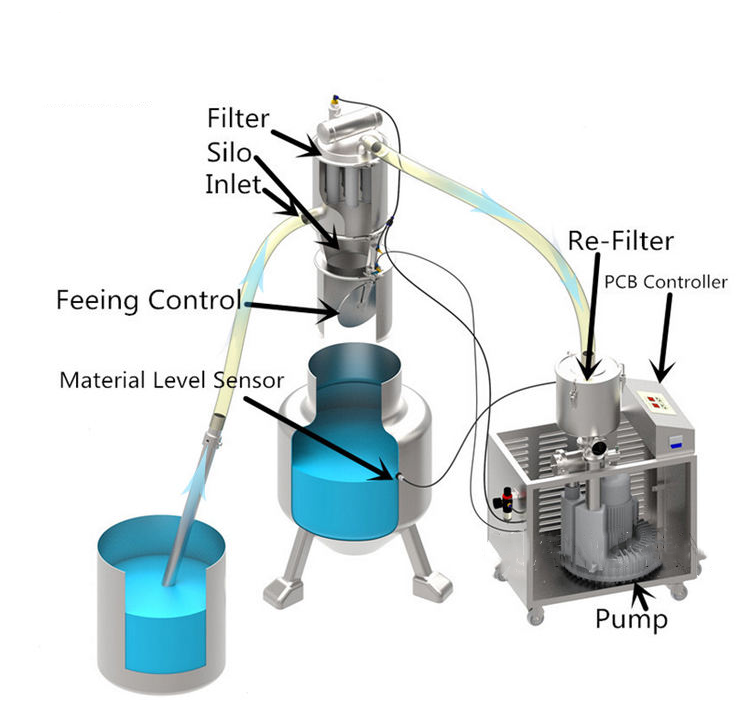

The Cement Vacuum Loading Machine uses a Roots vacuum pump or a water ring vacuum pump as its power source. It extracts air from a closed conveying system to create a stable negative pressure, leveraging the pressure differential to automatically convey cement powder.

Negative Pressure Suction: After the machine is started, the vacuum pump extracts air from the closed system consisting of the suction nozzle, conveying pipeline, and separation hopper, creating a strong negative pressure at the suction nozzle. The external atmospheric pressure pushes the cement powder through the suction nozzle and into the conveying pipeline, where the airflow propels it at high speed.

Air-Material Separation: After the cement powder enters the separation hopper with the airflow, the airflow velocity drops sharply due to the expansion of the hopper volume, causing the cement powder to settle to the bottom of the hopper under the action of gravity. A dust filter at the top of the hopper further captures fine cement dust, ensuring clean exhaust air.

Automatic Discharge: When the cement in the hopper reaches the preset level, the vacuum pump automatically shuts down, the pneumatic discharge valve at the bottom of the hopper opens, and the cement powder falls by gravity into downstream equipment.

What are the application scenarios for the Cement Vacuum Loading Machine?

With its advantages of closed-loop conveying and precise control, the Cement Vacuum Loading Machine has penetrated the entire cement production chain, from raw material storage to finished product shipment, achieving automated and clean material handling.

Cement Raw Material Storage: After raw materials such as cement powder and fly ash are transported to the plant by truck or train, traditional manual unloading or mechanical conveying can easily generate dust, and unloading efficiency is hampered by weather and labor constraints. The Cement Vacuum Loading Machine connects directly to the unloading port of the transport vehicle through a suction nozzle, utilizing vacuum suction to achieve closed unloading, eliminating dust leakage.

Production Process Transfer: Frequent material transfer is required between the grinding station and the homogenizing silo. Traditional belt or pneumatic conveying is prone to leakage, consumes a lot of energy, and is difficult to achieve with small batches and frequent transport. The Cement Vacuum Loading Machine connects both ends through a closed pipe, supporting flexible conveying of 50 meters horizontally and 30 meters vertically, adapting to complex plant layouts.

Additive batching: Cement production requires the addition of trace components such as gypsum and mineral powder. Traditional manual weighing or screw conveyors can easily lead to mixing errors, affecting product quality. The cement vacuum loader uses a frequency converter to adjust the vacuum pump speed, achieving precise flow control of 0.1-5 tons/hour.

Finished Product Packaging: When transporting finished cement from the storage to the packaging machine or bulk system, traditional mechanical conveying easily generates dust, and packaging efficiency is limited by manual operation. The cement vacuum loader transports cement to the packaging machine inlet through a closed pipe. Combined with a pulse dust collector, it achieves a dust concentration of ≤5mg/m³ in the packaging workshop, meeting environmental requirements.

What factors influence the price of a cement vacuum loading machine?

The price of a cement vacuum loading machine is influenced by a variety of factors, including material, specifications, configuration, brand, and production process.

Material: The material of components that come into contact with the material is a key factor. Carbon steel is relatively inexpensive and therefore relatively inexpensive. Stainless steel, especially corrosion-resistant 316L stainless steel, is significantly more expensive.

Specifications: Prices vary depending on equipment specifications and models, such as conveying capacity, lifting height, and conveying distance. Cement vacuum loaders with small throughput and short conveying distances are relatively inexpensive, while large, industrial-grade equipment with high throughput and long conveying distances is more expensive.

Configuration: The higher the configuration, the higher the price. For example, cement vacuum loaders equipped with specialized features such as advanced PLC control systems, CIP cleaning systems, SIP sterilization systems, and explosion-proof motors will cost significantly more than standard equipment.

Production Process: Manufacturers with advanced production processes can better ensure product precision, performance, and reliability during the manufacturing process, but this will increase production costs, which in turn affects the price.

Why choose us as your supplier for cement vacuum loading machines?

Choosing us as your supplier for cement vacuum loading machines guarantees expertise and quality. We have many years of experience in cement conveying. Our R&D team has a precise understanding of the characteristics of cement powder and uses highly wear-resistant materials, such as carbon steel lined with wear-resistant ceramic or wear-resistant steel, to significantly extend the service life of our equipment. We provide one-stop service, from customized solutions tailored to your production capacity, conveying distance, and other requirements, to ongoing after-sales maintenance. Numerous successful cases in cement companies attest to the high speed and stability of our equipment, helping you reduce material loss and improve production efficiency.

With "enclosed, high-speed, and safe" as its core values, the Cement Vacuum Loading Machine not only overcomes the dust pollution and efficiency bottlenecks of traditional conveying methods, but also, through its modular design and intelligent control, has become a benchmark solution for material handling in the Industry 4.0 era.