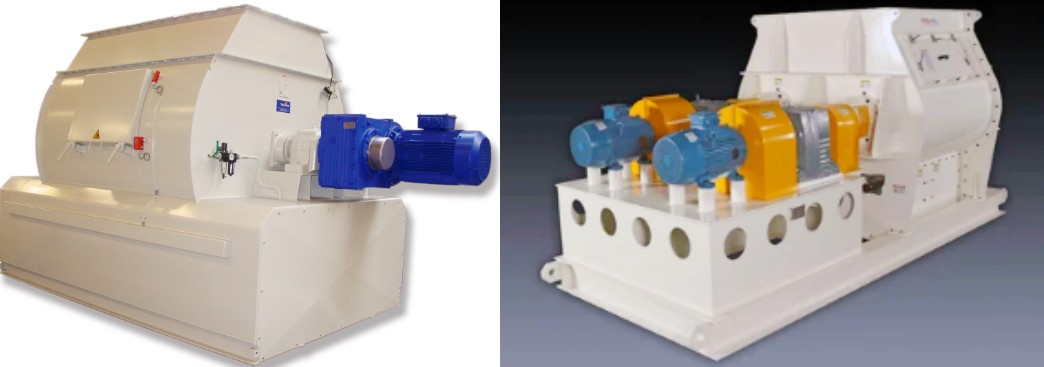

Paddle Mixer

A paddle mixer is an industrial mixer used to mix dry powder and liquid additives. The materials are interlaced during the throwing process to achieve uniform mixing. The discharge port has two types of large and small doors. The large door type discharges quickly and leaves no residue. This horizontal mixer has a wide range of applications, high mixing uniformity, and short mixing time.

Applicable materials: dry powder and liquid additives Application areas: chemical, cosmetics, battery and other industries Additional functions: There is pressure/vacuum in the mixer, and the jacket is used for cooling or heating

What is a paddle mixer?

A paddle mixer is an industrial equipment that achieves fluid mixing by rotating the paddle. Its core structure includes a motor, a reducer, a stirring shaft and a paddle. When working, the motor drives the paddle to rotate, generating centrifugal force to drive the liquid to form a circulation flow, thereby achieving the purpose of mixing.

Depending on the shape of the paddles (such as flat paddles, inclined paddles, folded paddles) and the arrangement of the paddles, the paddle mixer can meet the mixing needs of low-viscosity to medium-viscosity fluids, and some designs can even handle high-viscosity fluids. Its rotation speed is usually low, but the mixing efficiency is high, and it can quickly mix materials of different components evenly.

Classification of paddle mixers

Paddle mixers are mainly divided into single-shaft paddle mixers and double-shaft paddle mixers according to the number of their mixing shafts. Their main differences lie in structure and mixing effect.

Single-shaft paddle mixers have only one central rotating shaft, and the paddles are installed on this shaft. The structure is relatively simple and is suitable for mixing materials with good fluidity such as powders, granules or small amounts of liquid. The mixing action is relatively mild and is often used for mixing small and medium batches in industries such as pharmaceuticals and food.

Twin-shaft paddle mixers have two parallel, usually counter-rotating mixing shafts, each equipped with paddles, which can produce a stronger mixing action and higher mixing efficiency, and are more suitable for handling large batches, heavier or more complex materials, such as mixing solids and liquids. The twin-shaft design helps avoid material agglomeration and achieve more uniform mixing, and is widely used in industries such as chemical, agriculture, and construction.

What is the difference between a paddle mixer and a ribbon mixer?

| Features | Paddle mixer | Spiral mixer |

| Images |

|

|

| Mixing element | Paddles mounted on the shaft (can be of different shapes and numbers) | Usually a spiral ribbon around the central axis |

| Mixing action | Mainly shear and circulation, the mixing action is relatively mild | Mainly convection and shear, the axial and radial mixing of materials is stronger |

| Applicable materials | Suitable for powders, granules and small amounts of liquids with good fluidity | Suitable for powders, granules, pastes, and also good for viscous materials |

| Mixing uniformity | Suitable for less demanding mixing uniformity requirements | Usually can achieve higher mixing uniformity |

| Viscosity range | Low to medium viscosity | Medium to ultra-high viscosity |

| Typical speed range | Medium speed (30~150 rpm) | Extremely low speed (10~60 rpm) |

| Application scenarios | small and medium batch mixing in pharmaceuticals, food, etc., where the material is less destructive | chemical, food, feed, etc., where a higher mixing uniformity is required |

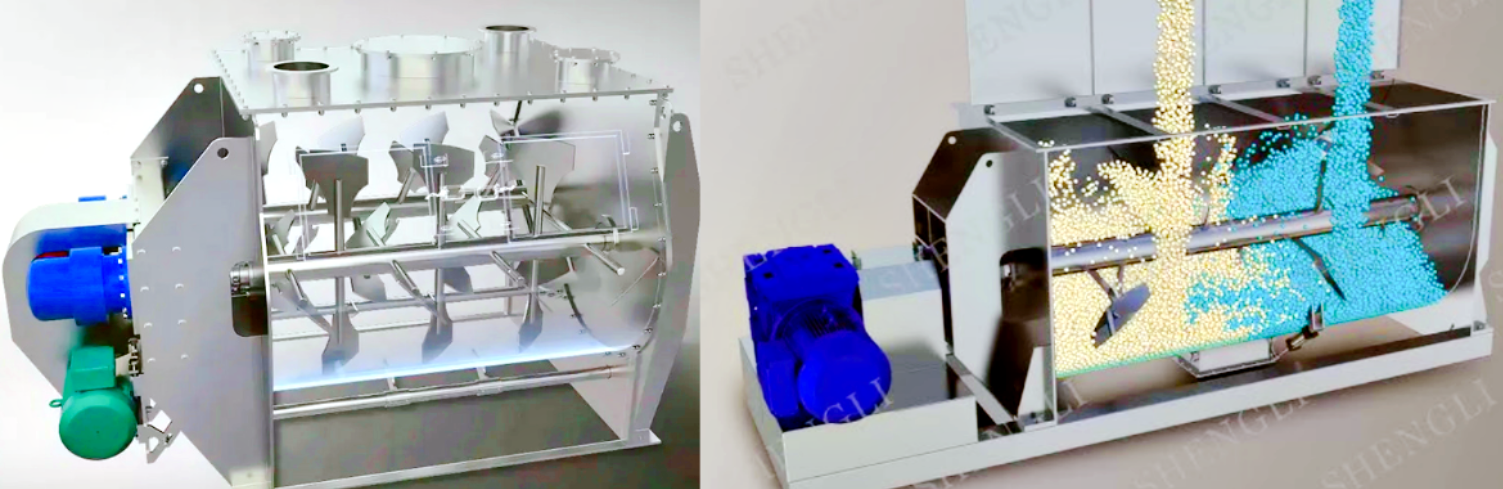

Working principle of paddle mixer

The rotating blades distribute and mix the materials in turn, and make each particle pass through the mixing chamber quickly and violently. Due to the determination of the blade angle, the mixer exhibits excellent axial and radial dispersion. Shorter mixing time and better mixing effect enhance the value of paddle mixers and make their application more extensive.

When working, the two shafts with counter-rotating blades rotate in different directions, driving the blades to rotate at different angles, so that the material is cyclically flipped in the axial and radial directions. Under the action of high linear speed, the material is thrown up and down in a weightless state.

Structure of paddle mixer

Paddle: usually made of flat steel, it is a component that directly contacts the material and realizes the mixing function. It is fixed to the hub or impeller by welding or bolts. The number of blades is generally 2, 3 or 4, and the form can be divided into two types: straight blade and folded blade.

Motor: Provides power source for the mixer and drives the blades to rotate. There are many common motor protection levels and insulation levels.

Reducer: Reduces the high speed of the motor to a low speed suitable for mixing, while increasing the torque so that the blades can mix at a suitable speed and force.

Mixing shaft: Connects the reducer output shaft and the blades, transmits power, and enables the blades to rotate around the axis.

Frame: Used to support components such as motors, reducers, and mixing shafts to ensure the stability of the entire mixing device. Carbon steel plates are usually welded to form a rigid truss support structure.

Shaft seal: Prevents material leakage in the mixing tank and also prevents external impurities from entering the mixing tank.

What are the advantages of paddle mixers?

High-speed mechanism is used to optimally and intensively mix dry powders in a relatively short cycle time. Batch or continuous types are available.

Flexible design with multiple mixing elements and high-speed choppers for mixing liquids and powders, center or bomb bay discharge to improve cycle time.

Excellent mixing homogeneity in short time

Abrasion resistant and heavy duty design for processing abrasive material

Big size discharge valve to minimize residues

Top high speed lump breaker device for de-agglomeration requirement

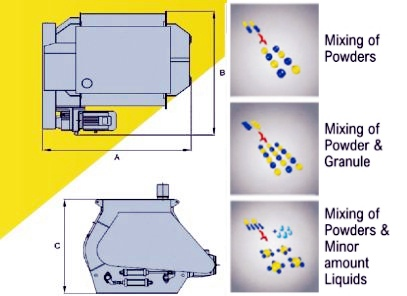

Paddle mixer technical specifications

| Gross Volume(L) | Effective Volume(L) | Overall Dimensions(mm) | Shaft Speed(rpm) | Approx.Weight (kg) | ||

| A(length) | B(width) | C(height) | ||||

| 200 | 80-120 | 1200 | 1200 | 750 | 43 | 270 |

| 300 | 120-180 | 1300 | 1400 | 930 | 43 | 450 |

| 500 | 200-300 | 1500 | 1600 | 1050 | 43 | 900 |

| 1000 | 400- 600 | 1900 | 1600 | 1200 | 43 | 1190 |

| 1500 | 600-900 | 2200 | 1700 | 1325 | 43 | 1600 |

| 2000 | 800-1200 | 2400 | 1700 | 1600 | 43 | 2700 |

| 3000 | 1200-1800 | 2500 | 1850 | 1760 | 43 | 3200 |

| 4000 | 1600 -2400 | 2900 | 2200 | 1850 | 29 | 4500 |

| 5000 | 2000-3000 | 3100 | 2300 | 2040 | 29 | 6000 |

| 6000 | 2400-3600 | 3300 | 2500 | 2100 | 29 | 7000 |

| 10000 | 4000-6000 | 3800 | 2900 | 2500 | 29 | 9000 |

| 130 00 | 5200-7800 | 4200 | 3200 | 2500 | 25 | 9700 |

| 15000 | 6000-9000 | 4400 | 3400 | 2600 | 25 | 11000 |

| 18000 | 7200-10800 | 4700 | 3700 | 2500 | 25 | 12500 |

Parameters of paddle mixer

| Model | A | B | C | Working Volume(m3) | Empty Weight(kg) |

| DH-0.05 | 1290 | 660 | 837 | 0.03 | 230 |

| wZ-0.2 | 1124 | 1110 | 720 | 0.12 | 260 |

| DH-0.4 | 1400 | 1250 | 1030 | 0.24 | 450 |

| DH-0.5 | 1450 | 1500 | 950 | 0,3 | 800 |

| DH-1 | 1800 | 1800 | 1350 | 0.6 | 1150 |

| DH-1.5 | 1850 | 1950 | 1180 | 0,9 | 1500 |

| DH-2 | 2200 | 2400 | 1600 | 1,2 | 2800 |

| DH-2.5 | 23 00 | 2300 | 1620 | 1.5 | 4200 |

| DH-4 | 2680 | 2400 | 1850 | 2.4 | 4500 |

| DH-5 | 2950 | 3050 | 2040 | 3 | 6000 |

| DH-6 | 3050 | 3250 | 2100 | 3.6 | 7000 |

| DH-10 | 3550 | 3150 | 2400 | 6 | 8000 |

| DH-12 | 4695 | 3180 | 2500 | 7.2 | 10500 |

| DH-15 | 4180 | 3960 | 2600 | 9 | 10000 |

| DH-20 | 5700 | 3700 | 2500 | 12 | 13000 |

What is a paddle mixer used for?

Thermal power plants, metallurgy, cement plants, pesticides, building materials, battery manufacturing, chemicals, paint and pigment industries, food and pharmaceutical industries, animal feed, sewage treatment, magnetic materials, ceramic industries.