Gangue impact crusher

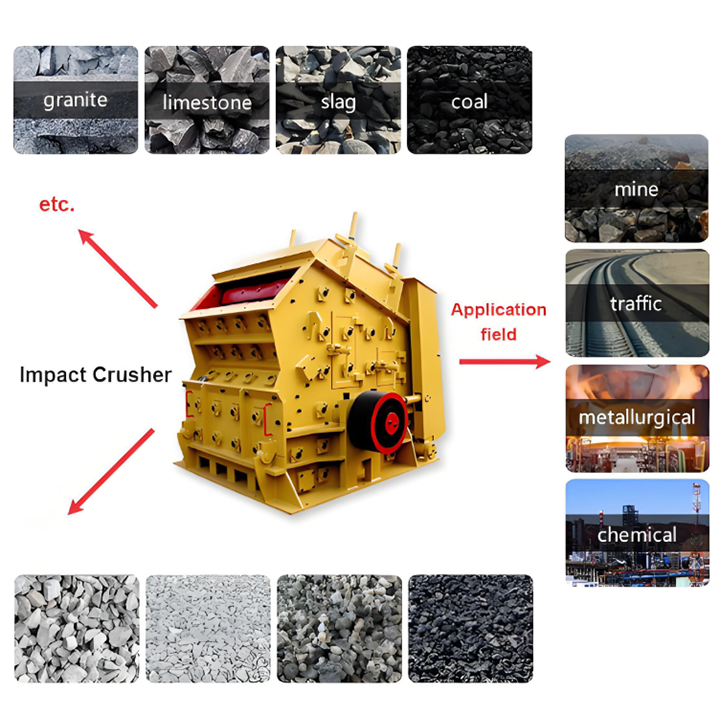

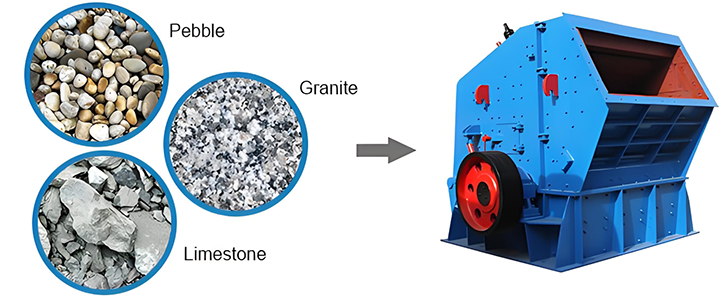

The Gangue impact crusher uses high-speed rotating hammers to impact gangue, which is then repeatedly impacted and ground by impact plates to crush it into the desired particle size. It is commonly used in mining, building materials, and other fields. Prices range from approximately $10,000 to $70,000. Feed size: ≤800mm Processing capacity: 50-600t/h Discharge size: <30mm (adjustable) Motor power: 90-400kW Rotor specifications: Φ1000×1050mm to Φ1500×2000mm

What is a Gangue impact crusher?

Gangue is solid waste discharged during coal mining and washing. It is a dark gray rock that is harder than coal and has a low carbon content. Gange impact crusher can be used for boiler fuel, building materials production, backfill, and land reclamation.

The Gangue impact crusher can process gangue of varying hardness and moisture content, achieving a crushing ratio of 50-60, simplifying the gangue processing process. The crushed particle size range is 5mm-50mm, and the output varies depending on the model, generally ranging from 2-400 tons/hour. Small units cost approximately $12,000-23,000 per unit, while large units cost over $100,000 per unit.

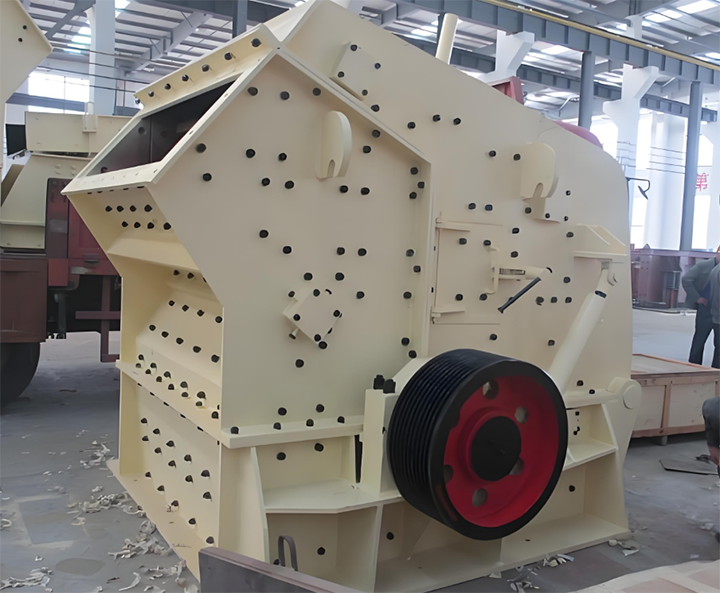

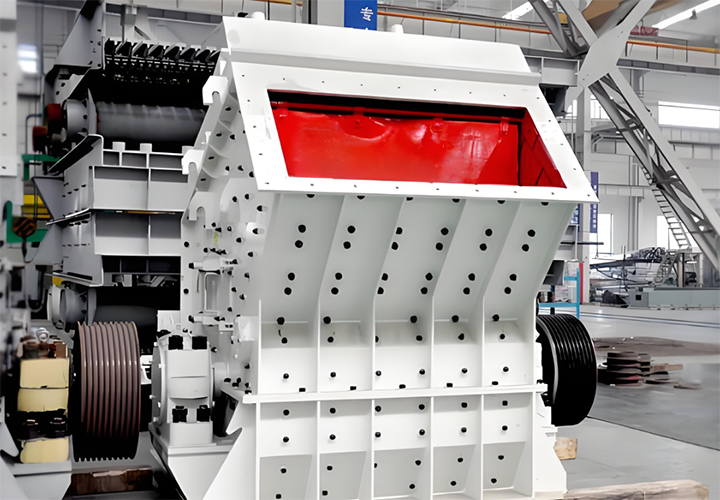

Gangue impact crusher structure

The structure of the Gangue impact crusher is shown in the figure below. The working principle is that after entering the crusher, the Gangue impact crusher is struck by the hammers on the high-speed rotating rotor, flung onto the impact plate inside the crusher housing for further crushing. The material then bounces off the impact plate and returns to the hammer zone, where it is struck again. This process repeats until the material is crushed to the desired particle size and discharged from the discharge port.

Gangue Impact Crusher Technical Data

| Model |

Rotor size D*L(mm) |

Feeder opening size(mm) |

Max feeding size(mm) |

Capacity (t/h) |

Power (kw) |

| PF-1007 | Φ1000X700 | 450X730 | 250 | 10-60 | 45 |

| PF-1010 | Φ1000X1050 | 400X1080 | 300 | 50-90 | 55 |

| PF-1210 | Φ1250X1050 | 450X1150 | 400 | 70-130 | 90 |

| PFW-1210 | Φ1250×1050 | 450x1150 | 400 | 75-140 | 90 |

| PFW-1214 | Φ1250X1400 | 480X1500 | 430 | 100-180 | 132 |

| PFW-1315 | Φ1320X1500 | 860X1520 | 500 | 130-220 | 200 |

| PFW-1320 | Φ1320X2000 | 900X2000 | 500 | 160-350 | 250 |

| PFW-1515 | Φ1500×1500 | 930x1550 | 600 | 200-400 | 280 |

| PFW-1520 | Φ1512X2000 | 930X2040 | 700 | 300-450 | 355 |

| PFW-1820 | Φ1800X2000 | 1620X2040 | 700 | 500-800 | 2X315 |

Gangue Impact Crusher Types

Gangue impact crushers can be categorized by rotor, structure, and function, with each type offering advantages for processing gangue. The following are specific types:

Gangue impact crusher classification by number of rotors

The number of rotors directly affects crushing efficiency, crushed particle size, and applicable material hardness. Both types of equipment are suitable for medium- to low-hardness gangue.

Single-rotor impact crusher: This crusher features a single, high-speed rotating rotor equipped with blow bars and a fixed impact plate within the crushing chamber. Upon entering the crushing chamber, gangue is first struck by the rotor's blow bars at high speed, then crushed against the impact plate for further crushing before being discharged from the discharge port. This type of impact crusher is suitable for small to medium-sized gangue crushing production lines, typically with a relatively small processing capacity of ≤200 t/h and a crushing particle size of ≤50 mm. It is commonly used in small-scale gangue processing near coal mine shafts and for crushing gangue for brickmaking.

Twin-rotor impact crushers consist of two rotors arranged in parallel or stepped configurations, with the two rotors rotating in the same or opposite directions. Each rotor is equipped with a hammer and features multiple impact plates. Gangue enters the first-stage rotor chamber for initial crushing. The crushed material then enters the second-stage rotor chamber, where it is impacted and ground again at high speed. The final particle size is controlled by adjusting the gap between the impact plates. These crushers are suitable for large-scale gangue processing projects, with a processing capacity of 300-800 tons/hour. They crush particles ≤ 20mm with a more uniform shape. They are commonly used in gangue aggregate production and large-scale gangue comprehensive utilization production lines.

Gangue impact crushers are classified by crushing chamber structure

Based on the number of stages in the crushing chamber (i.e., the number of times the material is crushed), they can be divided into single-stage and two-stage impact crushers. Single-stage and two-stage impact crushers are the most common types used for gangue crushing.

Single-stage impact crusher: The crushing chamber has only one impact plate. Material is crushed through a single impact and one impact. This shortens the process, has a simple structure, and reduces energy consumption. It is suitable for applications with smaller gangue feed sizes (e.g., feed size ≤300mm) and where the final particle size requirements are low, such as for roadbed filling.

Two-stage impact crusher: The crushing chamber has two impact plates. Material is first impacted by hammers (stage one), then by the first impact plate (stage two), and finally by the second impact plate (stage three). This achieves "three-stage crushing" (one hammer + two impact plates) for more complete crushing. It is suitable for applications with gangue feed sizes ≥500mm or where a finer and more uniformly graded final product is required, such as in the pretreatment stage of gangue before pulverization.

Gangue impact crushers are classified by special features.

To address the high moisture content and impurities of gangue, models with special features are available:

Anti-blocking gangue impact crushers: These crushers feature a larger feed inlet, an optimized, streamlined crushing chamber, and an adjustable impact plate angle to reduce gangue sticking and blockage caused by high moisture content. They are suitable for crushing in rainy southern regions or in humid environments with gangue moisture content ≥15%.

Gangue impact crushers with impurity removal: A metal detector and automatic impurity removal device are added to the feed inlet or crushing chamber entrance to detect and remove metal lumps from the gangue, preventing damage to the hammer and rotor. These crushers are suitable for crushing raw gangue transported directly from underground mines.

Mobile Gangue Impact Crusher: This station integrates an impact crusher, feeder, screen, and conveyor belt onto a mobile chassis, allowing for flexible movement to the gangue storage site. It is suitable for applications where dispersed gangue piles require on-site crushing and utilization, such as direct underground gangue crushing for filling in goafs.

Advantages of the Gangue Impact Crusher

Compared to jaw crushers and cone crushers, the Gangue impact crusher offers the following advantages: First, it adapts to the diverse nature of coal gangue. It specifically targets medium-hardness gangue (Mohs 3-6) that may contain impurities such as coal lumps and shale. It utilizes a "high-speed rotor impact + liner rebound crushing" mechanism to prevent clogging and wear. Second, it achieves uniform crushing, with adjustable rotor speed and impact plate gap for precise particle size control and a more uniform product shape. Finally, it boasts high processing efficiency, with a single unit capacity of 50-1000 tons/hour. This crushing system meets the requirements of coal mines processing hundreds to thousands of tons of material daily.

Gangue Impact Crusher Price

The price of a Gangue impact crusher ranges from US$1,000 to US$280,000. Some smaller gangue impact crushers may cost around US$1,000-5,000. A relatively reliable gangue impact crusher costs between $11,000 and $50,000. Large, high-performance gangue impact crushers may cost between $20,000 and $275,000. Prices are for reference only. We recommend contacting the manufacturer for a quote based on your actual operating conditions and desired output.

Gangue Impact Crusher Manufacturer

Our factory specializes in equipment manufacturing. When selecting a Gangue impact crusher, we can customize it based on your specific needs, including gangue moisture content, output volume, equipment functionality, and output particle size. We also offer 24/7 online customer service, so please contact us immediately if you have any questions about the equipment. We welcome on-site visits and trial runs with materials.

Gangue Impact Crusher Applications

In coal mining, the Gangue impact crusher can crush gangue associated with raw coal, either underground or on the surface, into a suitable particle size for use in filling goafs, reducing the risk of surface subsidence and enabling resource recycling. In the construction and building materials industry, coal gangue can be crushed into aggregates of varying specifications, used as concrete admixtures and wall brick materials, replacing traditional sand and gravel, reducing construction material costs and pollution. In highway and railway infrastructure, crushed coal gangue can be used as roadbed filler, meeting the project's requirements for aggregate strength and gradation, and resolving the problem of coal gangue stockpiling.