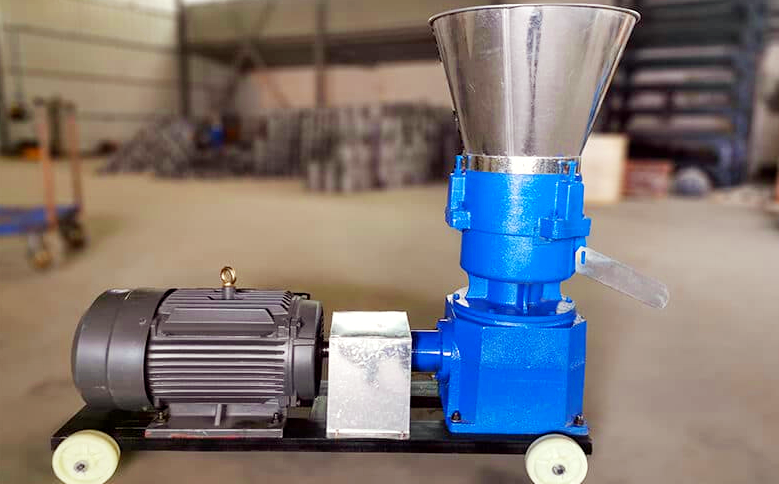

Animal for feed pellet machine

The equipment that processes powdered or mixed feed raw materials into cylindrical pellet feed adopts advanced roller and mold design to ensure efficient pressing and molding of materials

Production output: 0.1-2t

Type: ring die pellet machine, flat die pellet machine

Raw materials: rice, corn, wheat, barley, soybean, etc.

Voltage: 110-415 volts

Application scenarios: widely used in animal husbandry, poultry, aquaculture and other industries

What is an animal for feed pellet machine

Animal for feed pellet machine is a special equipment used to process powdered or bulk animal feed raw materials into pellet feed. Its core working principle is to force the mixed feed powder through the small hole and cut it into shape under the action of the mold and roller through mechanical extrusion.

What are the raw materials of animal feed pellets?

Animal for feed pellet machines are suitable for a variety of materials, including: corn, soybean meal, wheat bran, rice bran, grass meal, straw meal; fish meal, bone meal, additives, trace elements, etc.; in addition, they can also be used to prepare the following feed pellets: pig feed, chicken feed, duck feed, cattle feed, sheep feed, fish feed, rabbit feed, etc.

Classification of animal for feed pellet machines

Ring die pellet machine: The core component is a ring die (ring die), and the pressure roller is located inside or outside the die. The raw material enters between the ring die and the pressure roller through the feeding device. Under the strong pressure of the pressure roller, the raw material is forced to squeeze through the holes on the ring die. The extruded particles will be cut off by the cutter from the outside of the die to form uniform particles.

① Advantages: suitable for large-scale continuous production; stable particle formation

② Disadvantages: not suitable for materials with too high or too low fiber content

Flat die pellet machine: There is a flat circular die plate (flat die) above the machine, and there are many regularly arranged holes on the die plate. The raw materials enter the pelletizing chamber from above, and the powdered feed is forced into the holes of the die plate through the rotation and extrusion of the pressure roller. When the feed is squeezed out from the other side of the hole, it will be cut into pellets of a set length by the cutter.

① Advantages: suitable for small batch production; strong adaptability to materials

② Disadvantages: low production efficiency; relatively poor pellet quality, the hardness and density of the pellets are not as uniform as those produced by the ring die pellet machine;

Working principle of animal for feed pellet machine

Ring die pellet machine: mainly composed of feeding system, stirring system, pelletizing system, transmission system, etc. During operation, the material enters the agitator evenly through the feeder, is fully mixed and stirred with an appropriate amount of water or other additives in the agitator, and then enters the pelletizing chamber. In the pelletizing chamber, the ring die rotates, and the pressure roller rotates under the drive of the ring die. The material is squeezed and rubbed between the pressure roller and the ring die, squeezed into granules, and extruded from the die hole of the ring die to form pellet feed.

Flat die pellet machine: The main shaft drives the flat die to rotate, and the roller rolls on the surface of the flat die. The material is squeezed and rubbed between the roller and the flat die, and is squeezed into particles, extruded from the die hole of the flat die to make pellet feed.

What is the structural composition of the animal for feed pellet machine?

Inlet and outlet: The entrance of the raw material into the equipment, generally connected to a mixer or a feeding device, and a spiral feeder or a buffer bin can be installed. The particles at the outlet fall out automatically after being formed.

Conditioner (optional): humidifies, heats, and pre-matures the raw materials to improve the granulation effect, and increase the hardness and maturity of the particles. Generally used for medium and large models.

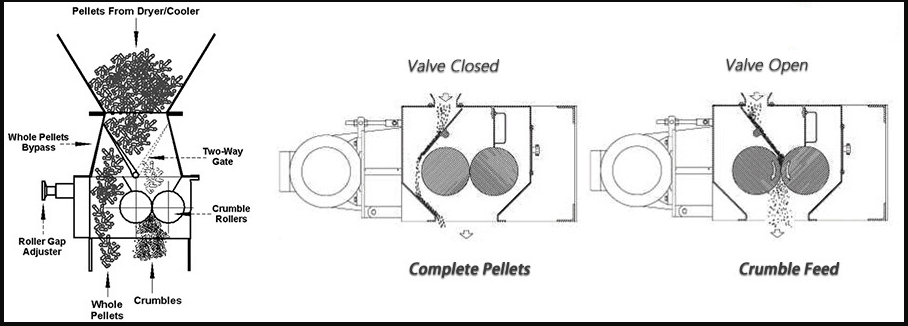

Mold system (die plate): The raw material is pressed into the die hole to form cylindrical particles. It is divided into two types: flat die and ring die. The diameter of the die hole determines the particle size (commonly 2-10mm).

Roller system: cooperates with the die to squeeze the material into the die hole. The roller material requires high strength and wear resistance. Flat die machines generally have 2-3 rollers; ring die machines are equipped with multiple rollers.

Cutter device: installed at the die outlet, responsible for cutting the continuously extruded feed strips into pellets of the required length, and the length of the pellets can be adjusted.

Main motor: provides power for the whole machine, drives the die or roller to operate, and the power ranges from 3kW to more than 100kW.

Reducer/pulley transmission system: controls the operating speed and provides torque, generally set between the main motor and the pressing device.

Frame and protective shell: supports the overall structure of the equipment and prevents personnel from contacting high-speed components during operation to ensure safe operation.

Characteristics of animal for feed pellet machine

Good pelleting effect: can directly press various crushed materials such as corn, soybean meal, straw, grass, rice husks, etc. into pellets, powdered feed and grass powder do not need or only need a little liquid to be added to pelletize, and the moisture content of pellet feed is basically the moisture content of the material before pelleting, which is conducive to storage.

High nutritional utilization rate: the pellets are of high hardness, smooth surface, and sufficient internal maturation, which can improve the digestion and absorption of nutrients, and can also denature the pancreatic enzyme resistance factors in grains and beans, reducing the adverse effects on digestion.

Wide applicability: equipped with a variety of aperture molds, it can adapt to the needs of different materials and different farmed animals, such as 2mm grinding discs are suitable for shrimp, small fish, crabs, young birds, etc., and 5MM grinding discs are suitable for pigs, horses, cattle, sheep, dogs, etc.

Technical parameters of animal for feed pellet machine

1. Small flat die feed pellet machine (suitable for family farming/small farms)

|

Model |

main motor power |

output (kg/h) |

die hole diameter (mm) |

applicable voltage |

machine weight (kg) |

applicable objects |

|

120 type |

3 kW |

60–100 |

2–8 |

220V/380V |

100 |

family farming, experimental use |

|

150 type |

4 kW |

90–150 |

2–8 |

220V/380V |

120 |

small farmers |

|

200 type |

7.5 kW |

200–300 |

2–10 |

380V |

210 |

small farms |

|

250 type |

15 kW |

300–500 |

2–12 |

380V |

380 |

Small and medium-sized farms |

II. Medium and large ring die feed pellet machine (suitable for large-scale farms/feed mills)

|

Model |

main motor power |

output (kg/h) |

die hole diameter (mm) |

ring die diameter (mm) |

machine weight (kg) |

features |

|

350 type |

30 kW |

600–1000 |

2–12 |

350 |

1000 |

high efficiency, suitable for chicken, duck, fish, etc. |

|

420 type |

75 kW |

1000–2000 |

2–12 |

420 |

1800 |

with conditioner, continuous production |

|

508 type |

110 kW |

2000–3000 |

2–12 |

508 |

2500 |

for commercial large-scale feed mills |

|

558 type |

132 kW |

3000–5000 |

2–12 |

558 |

3200 |

Can run continuously, high efficiency |

What can animal for feed pellet machines be used for

Animal for feed pellet machines are mainly used to press powdered raw materials (such as corn, soybean meal, straw, grass, rice husks, etc.) into pelleted feed, which is widely used in animal husbandry, aquaculture and poultry farming.

Specific uses include: producing highly nutritious and easily digestible pellet feed for poultry (such as chickens, ducks, geese), livestock (such as pigs, cattle, sheep), aquatic animals (such as fish, shrimp) and pets (such as rabbits and dogs). Small farmers use household pellet machines (such as 120 type, with an output of 100-300 kg/hour) to process self-prepared feed in rural family farms to reduce costs. Medium-sized models (such as 250 type, with an output of 500-800 kg/hour) are used in small and medium-sized farms to meet the daily needs of pig farms or chicken farms. Large feed mills are equipped with ring die pellet machines (output 3-20 tons/hour) for large-scale production, and other equipment to form an automated production line.

Price of animal for feed pellet machines

The price of animal for feed pellet machines varies greatly due to factors such as type, production capacity, and brand. The following is the approximate price range of different types of pellet machines (in US dollars):

Flat die pellet machines: The price is usually between US$200 and US$3,000. This type of pellet machine is suitable for small-scale production, has a simple structure, and is low in cost. It is a common choice for small farmers.

Ring die pellet machines: The price range is wide, generally between US$10,000 and US$100,000 or more. Among them, the price of vertical ring die pellet machines is mostly between US$10,000 and US$50,000. The price of horizontal ring die pellet machines is usually between US$20,000 and US$100,000 or more due to higher production efficiency and better performance. They are often used in large-scale feed production enterprises or large farms.

In addition, some small home or simple feed pellet machines may cost as low as $40 to $1,000. The prices of feed pellet machines for specific animals such as fish and poultry also vary. The price of fish feed pellet machines is generally between $2,000 and $20,000 or more, and the price of poultry feed pellet machines is usually between $1,000 and $10,000 or more.