Sidewall conveyor

The price of Sidewall conveyor varies depending on its conveying length, bandwidth, specifications of sidewalls and diaphragms. It usually ranges from US$150 to US$7,900.

Power: 200 watts

Dimensions: 1-100*0.2-1*0.3-2m/customizable

Width or diameter: 300/400/500/600mm/customizable

Voltage: 220v

Belt material: PVC/rubber/pu

Belt thickness: 1-3 mm

What is Sidewall conveyor?

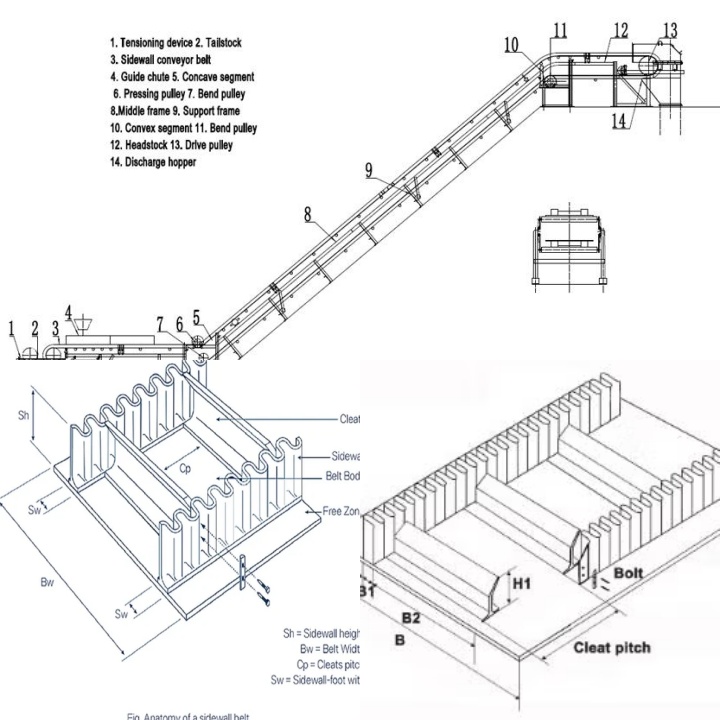

The main function of the Sidewall conveyor is to achieve stable transportation of bulk materials at large angles or even in the vertical direction. According to the inclination angle and structural characteristics, this type of conveyor can be divided into horizontal or small angle type, medium angle type, large angle or even vertical type, etc., to meet different material transportation needs. In terms of material handling capacity, the sidewall conveyor can handle material transportation volumes ranging from tens of kilograms per hour to thousands of tons per hour. Its single-machine conveying distance usually ranges from several meters to hundreds of meters.

Sidewall conveyor is a special belt conveyor that can stably transport bulk materials at large angles or even in the vertical direction by setting corrugated sidewalls on both sides of the conveyor belt and cooperating with cross partitions. According to the inclination angle, this type of conveyor is mainly divided into horizontal or small angle type (for anti-spillage), medium angle type (requires sidewalls and cross partitions), and large angle or even vertical type (makes full use of space, and the material is completely carried by the "material grid"). When selecting a model, multiple factors need to be considered comprehensively, such as conveying angle, material characteristics, handling capacity, and installation space.

What are the types of sidewall conveyors?

Sidewall conveyor is a special belt conveyor. It forms a U-shaped or trough-shaped conveying space by adding corrugated sidewalls on both sides of the conveyor belt, and often cooperates with a cross partition. The core purpose is to prevent materials from spilling during transportation. According to the inclination angle it adapts to, Sidewall conveyors can be divided into the following categories:

Horizontal or small angle sidewall conveyorThis type of sidewall conveyor is mainly used for horizontal conveying or small angle inclined conveying, usually with an inclination angle of less than 18°-20°.

Features: Although its inclination angle is not large, the sidewalls on both sides can effectively prevent materials, especially fine or fluid materials, from overflowing from the edge during transportation. Sometimes, according to the characteristics of the material, a lower cross partition is selectively installed to assist in pushing the material.

Medium angle sidewall conveyorThis type of sidewall conveyor can achieve medium degree of inclined conveying, and the inclination angle is usually between 20° and 45°.

Features: In this inclination range, materials can easily slide down due to gravity. Therefore, this type of sidewall conveyor is usually equipped with both corrugated sidewalls and transverse partitions. The corrugated sidewalls form lateral enclosures for the materials, while the transverse partitions separate the conveyor belt surface into separate "material grids", effectively preventing the materials from rolling down or sliding down. The height and spacing of the sidewalls and partitions are designed according to the inclination angle and material characteristics.

Large-angle or even vertical sidewall conveyorThis type of sidewall conveyor can achieve large-angle conveying, usually exceeding 45°, and can even reach 90° vertical conveying.

Features: It is also equipped with tall corrugated sidewalls and densely arranged transverse partitions. Due to the large inclination angle, the material is almost completely carried and pushed up by the "material grid" formed by the sidewalls and transverse partitions. This design can significantly save floor space and reduce intermediate transfer links. The conveyor belt base usually has good lateral stiffness to support the towering sidewalls.

What are the advantages of Sidewall conveyor?

Due to its unique design, Sidewall conveyor has shown many significant advantages in the field of material transportation, such as large-angle transportation, reduced material loss, strong adaptability and smooth operation.

Achieve large-angle transportation: This is the outstanding advantage of Sidewall conveyor. Through the corrugated sidewalls and diaphragms on both sides, it can transport materials from the horizontal plane to a vertical direction of up to 90 degrees. This saves space, especially in places where the plant area is limited or high-difference transportation is required, avoiding the series connection of multi-level ordinary conveyors and reducing transfer points.

Reduce material spillage and contamination: The sidewalls and diaphragms form a relatively closed conveying trough, which can effectively prevent materials from spilling from both sides or the rear end during transportation, especially when conveying at an angle or vertically. This not only reduces material loss, but also helps to keep the on-site environment clean and reduce dust flying.

Strong material adaptability: Sidewall conveyor can handle a variety of bulk materials, including powder, granular, blocky and some sticky or wet materials. Even during vertical conveying, the material is locked by the "grid", ensuring stable conveying and not easy to fall back.

Relatively simplified structure: Although the conveyor belt itself is relatively special, compared with some complex vertical lifting equipment (such as the maintenance of bucket elevators under certain working conditions), Sidewall conveyor can simplify the overall conveying system in specific applications. It reduces the number of intermediate transfer links and equipment, which may reduce the complexity of the system and potential failure points.

Smooth operation and less damage to materials: Compared with traditional bucket elevators, Sidewall conveyor uses continuous belt conveyor, and the material is smoothly lifted in the "grid" with less impact and vibration. This can effectively reduce the breakage rate for fragile materials or materials that need to maintain integrity.

Sidewall conveyor parameters

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

| Baseband Type |

Strength (N/mm) |

Coating thickness (mm) |

Weight (G/m2) |

Min Pulley Diameter (mm) |

|

250/2 | 2:2 | 9.40 | 200 |

| 400/3 | 4:2 | 13.50 | 315 | |

|

400/3+2 | 4:2 | 12.10 | 315 |

| 500/3+2 | 4:2 | 12.60 | 400 | |

| 630/4+2 | 4:2 | 14.40 | 500 | |

| 800/5+2 | 4:2 | 16.10 | 630 | |

| 1000/5+2 | 4:2 | 17.80 | 800 | |

| 1250/5+2 | 4:2 | 18.25 | 1000 | |

|

315/2+2 | 4:2 | 13.70 | 315 |

| 400/3+2 | 4:2 | 14.80 | 315 | |

| 500/3+2 | 4:2 | 15.20 | 400 | |

| 630/4+2 | 4:2 | 16.70 | 500 | |

| 800/5+2 | 4:2 | 18.00 | 630 | |

| 1000/5+2 | 4:2 | 19.50 | 800 | |

| 1250/5+2 | 4:2 | 21.40 | 1000 | |

|

1600 | 8:8 | / | 1250 |

| 2000 | 8:8 | / | 1250 | |

| 2500 | 8:8 | / | 1400 | |

| 3150 | 8:8 | / | 1400 | |

| 3500 | 8:8 | / | 1600 | |

| 4500 | 8:8 | / | 1600 | |

| 5000 | 8:8 | / | 1600 | |

| 5400 | 8:8 | / | 1800 | |

| 6000 | 8:8 | / | 1800 |

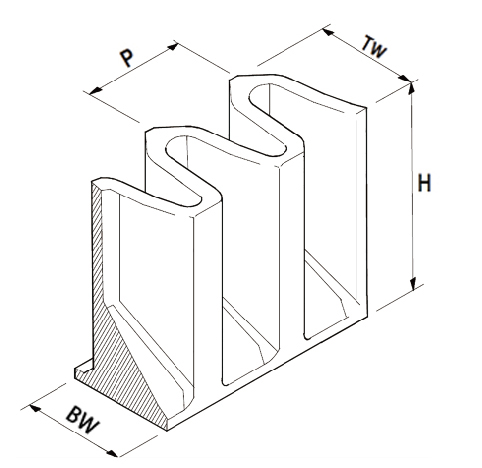

| Sidewall Height (H) | Wave Crest Width (TW) | Wave Base Width (BW) | Wave Spacing (P) | Weight (kg/m) |

|

| 100 | 44 | 50 | 42 | 2.34 | |

| 120 | 44 | 50 | 42 | 2.78 | |

| 160 | 66 | 75 | 63 | 4.42 | |

| 200 | 66 | 75 | 63 | 5.82 | |

| 240 | 66 | 75 | 63 | 8.49 | |

| 300 | 88 | 100 | 84 | 12.48 | |

| 400 | 88 | 100 | 84 | 17.60 | |

| 500 | 110 | 125 | 105 | 24.40 | |

| 630 | 110 | 125 | 105 | 31.50 |

| Cleat Type (mm) | Cleat Height (mm) | Sidewall Height(mm) | Bottom Width (mm) | Weight (kg/m) | Minimum Pulley Diameter (mm) |

C |

90 | 100 | 110 | 2.81 | 250 |

| 110 | 120 | 110 | 3.27 | 315 | |

T |

90 | 100 | 110 | 2.7 | 250 |

| 110 | 120 | 110 | 3.23 | 315 | |

| 140 | 160 | 160 | 5.49 | 400 | |

| 180 | 200 | 160 | 6.67 | 500 | |

| 230 | 240 | 160 | 8.6 | 630 | |

TC |

90 | 100 | 110 | 3.22 | 250 |

| 110 | 120 | 110 | 3.94 | 315 | |

| 140 | 160 | 150 | 5.49 | 400 | |

| 180 | 200 | 150 | 6.81 | 500 | |

| 230 | 240 | 160 | 8.68 | 630 | |

| 280 | 300 | 180 | 14.9 | 800 | |

TCS |

230 | 240 | 160 | 13.8 | 630 |

| 280 | 300 | 160 | 15.3 | 800 | |

| 360 | 400 | 230 | 22.8 | 1000 | |

| 470 | 500 | 230 | 30.8 | 1250 |

How does the sidewall conveyor work?

The sidewall conveyor works on a friction-driven belt conveying mechanism, combined with its uniquely designed corrugated sidewalls and diaphragms to achieve stable conveying of materials at large angles or even in the vertical direction. The core workflow is as follows:

Power transmission and belt operation: The drive device (usually composed of an electric motor and a reducer) drives the drive roller to rotate. Through the friction between the drive roller and the conveyor belt, the circular conveyor belt is driven and starts to run continuously. The conveyor belt bypasses the head, tail and possible redirection rollers to form a closed loop.

Material loading and "grid" formation: The material enters from the feed end of the conveyor and is placed on the surface of the running conveyor belt. Due to the corrugated sidewalls attached to both sides of the conveyor belt and the diaphragms set at equal intervals, the conveyor belt surface is divided into independent spaces that are similar to "grids" or "pockets". When the material enters these "grids", it is effectively contained and fixed.

Stable lifting at large angles: As the conveyor belt continues to operate, these "grids" carrying materials begin to enter the inclined or vertical lifting section. At this time, the corrugated sidewalls provide lateral support to prevent the material from spilling from the edge, while the diaphragms provide upward thrust and prevent the material from sliding down or rolling back under the action of gravity. The material is stably "lifted" and moves upward along the inclined or vertical path of the conveyor belt.

Material unloading: When the conveyor belt reaches the drive roller (or a specific unloading point) at the discharge end, the conveyor belt will bend around the roller. At this time, due to the inertia or gravity, and the bending of the conveyor belt, the shape of the "material grid" changes, and the material is separated from the "material grid" and discharged through the discharge port, completing the entire conveying process. In order to ensure that the material is completely unloaded, a cleaning device is sometimes used.

What are the uses of Sidewall conveyor?

Sidewall conveyor plays an important role in many industrial fields because of its ability to stably transport materials at large angles or even in the vertical direction. Its main uses can be summarized as follows:

Continuous transportation and process connection: Sidewall conveyor realizes continuous and uninterrupted material transportation. In many production processes, material transfer between different equipment needs to be carried out continuously to ensure smooth production. Sidewall conveyor can seamlessly connect process links at different heights.

Prevent material spillage: Because the corrugated sidewalls and diaphragms on both sides form a closed conveying trough, Sidewall conveyor can effectively prevent bulk materials from spilling from both sides or the rear end during transportation, especially at large inclinations or high speeds. This is crucial for conveying materials with high dust, odor, or environmental cleanliness requirements, and helps to reduce material loss.

Adapt to diversified material transportation: Sidewall conveyor can adapt to bulk materials with various physical properties, including powder, granular, block materials, and even some wet or sticky materials. Its "material grid" design ensures that the material can be stably carried and pushed up even at steep inclination angles, and is not easy to flow back or accumulate, which broadens the scope of application of the conveyor's materials.

Height difference transportation and space optimization: This is the core purpose of Sidewall conveyor. When materials need to be lifted from a lower location to a higher silo, equipment feed port or different floors, traditional flat belt conveyors often require multiple stages in series, occupying a large amount of horizontal space. Sidewall conveyors can convey materials at a large angle (even close to 90 degrees vertical), significantly saving valuable floor space and achieving vertical transfer of materials in a limited space.

In short, Sidewall conveyors solve the problem of conveying bulk materials at large angles or even vertically through their unique structural advantages, and are important equipment for achieving space optimization and continuous conveying.

What are the applications of Sidewall conveyor?

As a special belt conveyor, the core of Sidewall conveyor is to solve the problem of stable transportation of bulk materials at large angles or even in the vertical direction. The equipment can realize the height difference transfer of materials in a limited space, such as lifting materials from a lower processing point to a higher storage facility, or continuously conveying materials between multi-storey factories, thereby effectively saving horizontal floor space. It is suitable for bulk materials of various particle sizes and forms, including powder, granular and small block materials. In the mining and metal smelting industries, it can lift bulk materials such as coal, ore, limestone, coke directly from the depths of the mine to the ground, or feed the crushed materials into high-level equipment such as mills and blast furnaces. In some storage and logistics centers with high requirements for space utilization, Sidewall conveyor is used to transfer packaged boxes, bagged items or bulk particles between different floors. In addition, in many industries such as agriculture, metallurgy, and casting, Sidewall conveyor is an important choice for any scene where bulk materials need to be lifted continuously, at large angles or vertically. In addition, the corrugated sidewalls and baffles on both sides of the conveyor belt effectively confine the material in the "grid", preventing it from falling back or spilling from the side even at steep inclination angles. This feature helps reduce material loss and improve the cleanliness of the on-site environment. Sidewall conveyor also enables continuous and smooth material flow, which helps to connect different height links in the production process. It has advantages over some traditional vertical lifting equipment when handling materials that need to maintain material integrity or reduce impact, and can reduce material damage during transportation. Therefore, its application scenarios are widely used in various production and logistics links that require space utilization and continuous height difference transportation of materials.

As a mature material conveying equipment, the working principle of Sidewall conveyor is based on a conveyor belt with corrugated sidewalls and baffles, and the continuous transfer of materials is achieved through friction drive. This equipment structure enables it to effectively prevent materials from spilling during transportation and adapt to material conveying tasks at various inclination angles. When transferring materials from low to high, or adjusting material layout in places with limited space, Sidewall conveyor provides a feasible material conveying solution.