Screw conveyor

The price of screw conveyors varies from $100 to $9,000, depending on factors such as their material, length and whether they include customized functions.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel/Plastic

Why use screw conveyor?

Screw conveyor is a common material conveying device that uses a central shaft or shaftless spiral blade to rotate in the trough to push the material in a horizontal, inclined or vertical direction. The equipment is mainly composed of spiral blades, bearing supports, drive mechanisms and closed or semi-enclosed troughs. After the material enters the trough, it is transported forward under the push of the blades and transferred or unloaded at the outlet. The layout of the screw conveyor can be adjusted according to the on-site space and process requirements. It can be laid horizontally or installed at an angle or vertically. The equipment has a compact structure and occupies a relatively small area. The blades and trough can be cleaned through the inspection port during maintenance. The applicable material range covers dry powder, granules, small pieces and semi-fluid materials of a certain viscosity.

Screw conveyor can be divided into horizontal, inclined and vertical conveying modes according to its installation angle, and each mode corresponds to different material height difference handling requirements. In terms of handling capacity, screw conveyor can handle material conveying tasks ranging from small to large quantities, and its handling capacity depends on the screw diameter, rotation speed and material characteristics. At the same time, its design allows the conveying distance to be adjusted within a certain range, ranging from a few meters to tens of meters. The structure of screw conveyor enables it to adapt to a variety of material forms, including powder, granular and small block materials. Its diverse configuration options allow manufacturers to provide customized equipment solutions according to specific working conditions to meet specific material conveying requirements.

What are the types of screw conveyors?

Screw conveyor, also known as auger conveyor, is a device that pushes materials in a U-shaped trough or circular tube for conveying through rotating spiral blades. According to its installation method and conveying angle, screw conveyor can be divided into two categories: classification by conveying angle and classification by mobility.

Classification by conveying angle

Horizontal Screw conveyorHorizontal Screw conveyor is a more common type, and materials are conveyed in the horizontal direction. This type is usually used for short-distance material transportation, such as conveying materials from one container to another, or distributing materials in a production line. It has a simple structure and is easy to maintain, and is widely used in industries such as grain, chemicals, and building materials.

Inclined Screw conveyorThe inclined Screw conveyor is used to lift materials from a lower place to a higher place. Its inclination angle is usually between 0 degrees and 90 degrees (usually less than 45 degrees, because too large an inclination angle will affect the conveying efficiency and stability). Depending on the inclination angle, the conveying efficiency will vary. Inclined Screw conveyor is often used in situations where vertical lifting or crossing height differences is required, such as conveying materials between silos, hoppers, and processing equipment.

Vertical Screw conveyorVertical Screw conveyor is used to lift materials completely vertically. Compared with inclined Screw conveyors, vertical Screw conveyors usually require higher speeds and special spiral blade designs to ensure that materials can be effectively lifted without falling back. This type is suitable for small spaces where materials need to be lifted to a great height, such as in the conveying system of some powder or granular materials.

Classification by mobility

Fixed Screw ConveyorFixed Screw Conveyor is a device permanently installed at a specific location. They are usually part of a large production line or material handling system and are used to continuously convey large amounts of materials on a fixed path. This type of conveyor has a sturdy structure, stable operation, and relatively low maintenance requirements, making it suitable for long-term, large-volume material conveying tasks.

Mobile Screw ConveyorMobile Screw Conveyor is designed with wheels or universal wheels, which can be easily moved from one location to another. This flexibility makes them very suitable for occasions where the conveying location needs to be changed frequently, such as grain loading and unloading on farms, conveying cement or sand on construction sites, or transferring materials between different production areas. Mobile Screw Conveyors are usually small in size and easy to operate, but their conveying capacity and distance may not be as good as fixed conveyors.

What is the principle of Screw Conveyor?

The working principle of Screw Conveyor is to use rotating spiral blades to push bulk materials forward in a closed U-shaped trough or round tube. When the motor drives the spiral shaft to rotate, the spiral blade fixed on the shaft pushes the material axially, similar to a continuously rotating screw turning the nut forward. Due to the gravity of the material itself and the friction between the material and the groove wall, the material does not rotate with the spiral blade, but overcomes these resistances and realizes uniform and continuous conveying under the action of the spiral blade. Specifically, under the action of the spiral blade, the material is not only pushed forward by the spiral blade, but also affected by its own gravity, the friction of the conveyor shell wall and the internal friction of the material. The combined effect of these forces makes the material form a continuous spiral motion in the spiral groove, thereby realizing smooth conveying from the feed port to the discharge port. The material does not simply rotate with the blade, but moves forward along the spiral ascending path through the pushing of the blade and the friction between itself and the shell. The conveying speed and efficiency mainly depend on the diameter, pitch, rotation speed of the spiral blade and the characteristics of the material (such as fluidity, viscosity, particle size, etc.). This conveying method has the advantages of simple structure, good sealing, easy maintenance and multi-point feeding and discharging. It is widely used in short-distance horizontal or inclined conveying of granular, powdery and small block materials.

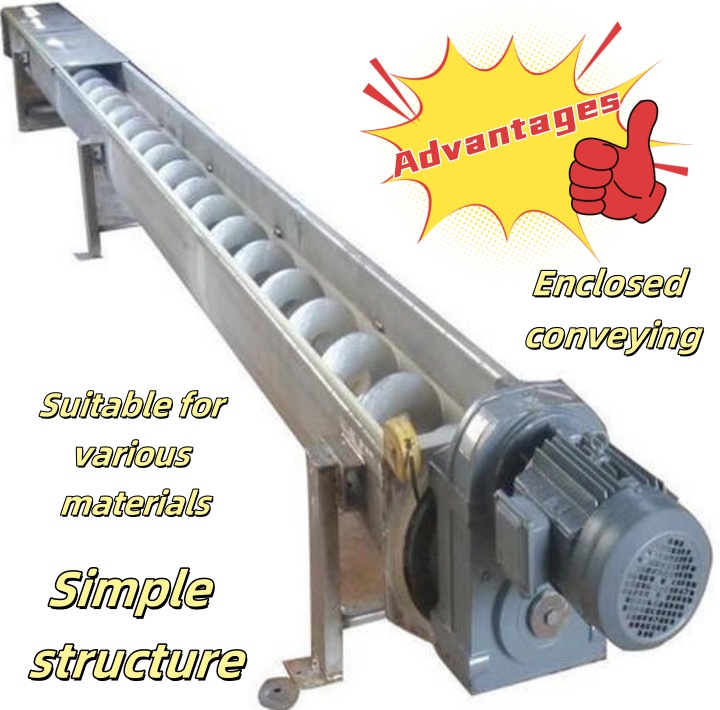

What are the advantages of screw conveyor?

With its unique structure and working principle, screw conveyor has shown significant advantages in many industrial fields, such as wide material adaptability, flexible configuration, and diverse functions. The following are its main advantages:

Wide material adaptability: screw conveyor can handle various types of bulk materials, whether it is dry, free-flowing powder (such as cement, flour), or wet, sticky semi-solid (such as sludge, food residue, bone meal), or even small pieces of materials (such as grain, sand and gravel). By adjusting the design of the spiral blade (such as shaftless spiral) and the material, it can effectively cope with the characteristics of different materials, including materials with a certain temperature.

Flexible configuration and versatility: screw conveyor is very flexible in design and can be installed horizontally, tilted or vertically according to site and process requirements, especially suitable for places with limited space. It can not only transport materials, but also realize multiple functions, such as multi-point feeding and discharging, and multiple feeding and discharging ports can be set to facilitate the loading and unloading and distribution of materials at different locations. Mixing and stirring, during the conveying process, the rotation of the spiral blade can also mix and stir the materials to a certain extent, and even break some block materials. Heating, cooling or drying, by designing a jacket or hollow structure inside the conveyor housing or spiral blade, the temperature of the conveyed material can be controlled. Metering and feeding, by accurately controlling the speed of the spiral, the screw conveyor can be used as a metering device to achieve accurate control of the material conveying amount.

Good sealing: Screw conveyors usually adopt a fully enclosed design to effectively prevent materials from leaking, flying or being contaminated by the outside world during the conveying process. This is crucial for handling dusty, toxic, harmful or flammable and explosive materials, which can reduce material waste and reduce the impact on the environment.

Simple structure and easy maintenance: The structure of the screw conveyor is relatively simple, mainly composed of a screw shaft, blades, a trough body, a drive device, etc., with few moving parts. This makes its installation, operation and daily maintenance relatively simple, and the failure rate is relatively low, thereby reducing operating costs and downtime.

Screw conveyor parameters

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

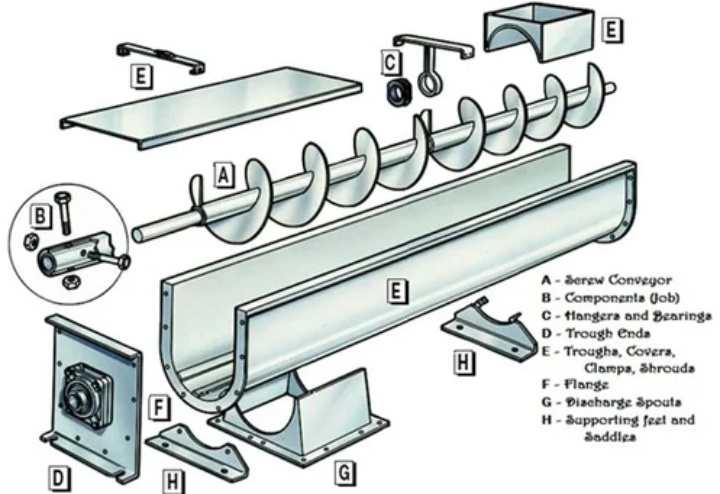

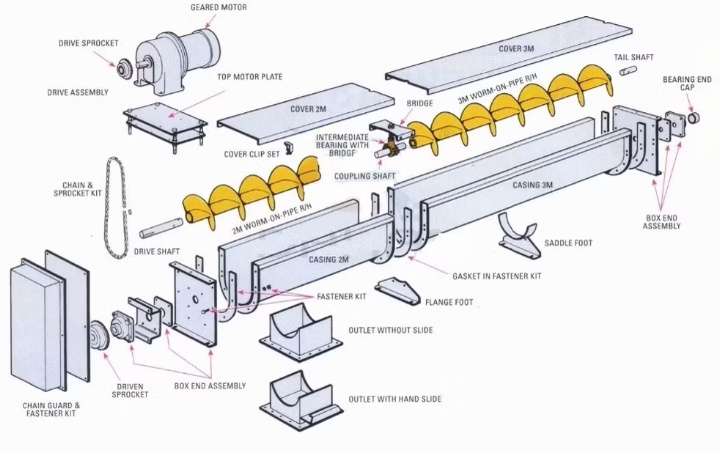

What are the structures of the screw conveyor?

Screw conveyor, as a common bulk material conveying equipment, has a relatively simple structure but ingenious design. It is mainly composed of a screw, a conveying trough, a feed port and a discharge port, a drive device, bearings and hanging bearings, a cover plate and a seal:

Screw (conveyor screw)

The screw is the key working part in the screw conveyor, which is directly responsible for pushing the material forward. It usually consists of the following parts:

Screw blades: The shape and size of the screw blades will vary according to the nature of the conveyed material and the conveying requirements. Common ones are solid spiral surfaces, belt spiral surfaces, and blade spiral surfaces.

Shaftless screw: In this design, there is no central shaft, and the blades rotate by contact with the trough body. It is particularly suitable for conveying materials with strong viscosity, easy to entangle or with large pieces, avoiding the problem of materials winding around the shaft.

Screw shaft: A solid or hollow cylindrical shaft, on which the screw blades are usually welded or fixed. The screw shaft is connected to the drive device through a coupling to transmit power. In the shaftless screw conveyor, there is no traditional screw shaft.

Conveying trough (or shell)

The conveying trough is the outer envelope of the spiral body, providing a closed channel for the material and supporting the spiral body.

U-shaped or circular:

U-shaped trough: commonly used in horizontal or small angle conveyors, convenient for material entry and exit and cleaning, but relatively poor sealing.

Circular tube: mostly used in large angle or vertical conveyors, with better sealing, can effectively prevent dust spillage and material contamination, but relatively inconvenient to clean.

Feed port and discharge port

Feed port: the entrance of the material into the conveyor, usually located at the top or side of the conveying trough body. Its design should ensure smooth entry of materials to avoid blockage.

Discharge port: the outlet of the material leaving the conveyor, which can be set at the end or middle of the conveying trough body. According to the needs, it can be designed as a single-point discharge or a multi-point discharge.

Drive device

The drive device is a device that provides rotational power for the spiral body, usually composed of a motor, a reducer, and a coupling. The drive unit is generally installed at the feed end or discharge end of the screw conveyor, and drives the screw shaft to rotate through gears, chains or direct connections.

Bearings and hanging bearings

In order to support the screw shaft and ensure its smooth rotation, the screw conveyor is usually equipped with head and tail bearings. The bearings located at both ends of the screw conveyor bear the axial and radial forces of the screw shaft and connect the screw shaft to the drive unit or tail support. Hanging bearings (intermediate bearings) will be set up along the inside of the conveying trough. These bearings are usually sliding bearings and are designed to be wear-resistant, maintenance-free or easy to replace to adapt to the wear and contamination of the material.

Cover and seals

Cover: Covering above the U-shaped trough or as part of the circular tube, it is used to close the conveying channel to prevent material spillage and foreign matter from entering.

Seals: Seals (such as packing seals and mechanical seals) are installed at the connection between the bearing seat and the trough, as well as at the inlet and outlet, to prevent material leakage or dust spillage and ensure the safety of the conveying process.

What are the applications of screw conveyor?

As a versatile bulk material conveying equipment, screw conveyor has a wide range of application scenarios, mainly reflected in the following aspects:

Horizontal conveying of materials: It can stably convey various granular, powdered or small block materials in the horizontal direction. This application is indispensable in many production processes that require continuous and smooth transfer of materials.

Inclined conveying of materials: When materials need to be lifted from a lower height to a higher height, or across a certain height difference, screw conveyor can convey them at a certain tilt angle. This method effectively solves the problem of height difference conveying and avoids the use of other more complex lifting equipment.

Vertical conveying of materials: When space is limited or materials need to be lifted vertically to a high place, screw conveyor can be used as an effective vertical lifting equipment. Although its conveying efficiency may be slightly lower than other vertical conveying equipment (such as bucket elevators), it provides a compact and cost-effective solution under certain conditions.

Measuring and control of materials: By accurately controlling the speed of the screw, screw conveyor can achieve accurate measurement and control of the material conveying amount. This makes it play an important role in production processes that require quantitative feeding or batch processing to ensure the accuracy of material input.

Mixing and stirring of materials: During the conveying process, the rotating motion of the spiral blade not only pushes the material forward, but also mixes and stirs the material to a certain extent.

Cooling, heating or drying of materials: Some specially designed screw conveyors, such as models with jackets or hollow screws, can control the temperature (cooling or heating) while conveying materials, and even achieve a preliminary drying process.

Price of screw conveyor

The price of screw conveyor varies depending on many factors, ranging from $100 to $9,000 or even higher. Due to its highly customized nature, its price varies greatly. The price of screw conveyor is mainly affected by the following key factors:

Material: Carbon steel is low in price and is suitable for conveying ordinary, non-corrosive and low-hygiene materials such as grain, coal, sand and gravel. Stainless steel (such as 304, 316L) is significantly more expensive than carbon steel. Stainless steel has excellent corrosion resistance, high temperature resistance and hygiene. Among them, 316L stainless steel is more expensive and suitable for occasions with higher corrosion resistance requirements. Special alloys are designed for extreme working conditions (such as high temperature, strong corrosion, and strong wear). Nickel-based alloys or other special materials may be required, which will be very expensive.

Length: The longer the conveyor, the more screw shafts, troughs, and support structures are required, and the price will naturally be higher.

Diameter: The larger the diameter of the spiral blade, the greater the conveying volume and the higher the manufacturing cost.

Shafted spiral and shaftless spiral: Shaftless screw conveyors are usually more expensive than shafted screw conveyors of the same size due to their unique spiral blade design and load-bearing method.

Trough shape (U-shaped trough or tubular): Tubular conveyors are usually slightly more expensive than U-shaped troughs due to their fully enclosed structure.

Tilt angle and vertical height: The larger the tilt angle, or the screw conveyor that needs to be lifted vertically, the cost will increase due to the need for stronger driving force, more sophisticated balance design or special structure.

Multi-point feeding and discharging: Increasing the number of feeding and discharging ports and related openings, flanges, gates and other components will also increase the total price.

Motor power: The greater the conveying capacity, the longer the conveying distance, and the greater the conveying inclination, the greater the motor power required, and the higher the price accordingly.

Reducer brand and type: Different brands and types of reducers (such as cycloidal pinwheel reducers, gear reducers) and their transmission efficiency, durability, etc. will affect the price.

Sealing requirements: Higher sealing levels (such as airtightness and explosion-proof) require more precise processing and more advanced seals, which will increase costs.

Surface treatment: Such as polishing, sandblasting, coating, etc., especially food-grade polishing, will significantly increase costs.

Additional functions: Such as heating/cooling jackets, stirring functions, weighing modules, variable frequency speed regulation systems, automatic control systems, etc., will significantly increase prices.

Screw conveyor manufacturers

Screw conveyor manufacturers usually have professional technical teams and production facilities, and can provide solutions based on diverse market needs. When manufacturers produce screw conveyors, they first focus on their variety of types. This includes equipment that provides different conveying angles, such as horizontal screw conveyors suitable for horizontal material transmission, inclined screw conveyors for height difference transmission, and vertical screw conveyors for vertical lifting needs. At the same time, manufacturers will also produce equipment with different mobile performance, such as fixed screw conveyors for fixed installation and mobile screw conveyors that can be flexibly moved to meet the needs of different operating scenarios. In addition to standardized product lines, customized production is an important service capability of screw conveyor manufacturers. Customers handle a wide variety of materials (such as powders, granules, small pieces, sticky, corrosive or abrasive materials), as well as specific process flows and on-site space restrictions. Manufacturers need to have a deep understanding of customers' detailed needs, including material characteristics, conveying capacity, conveying distance, feeding and discharging methods, operating environment temperature, whether explosion-proof or hygienic requirements are required, etc. Based on this information, the manufacturer will carry out personalized design, including selecting the appropriate spiral blade form (such as solid type, belt type, blade type or shaftless type), determining the material (such as carbon steel, stainless steel 304/316L or special alloy) and shape (U-shaped groove or round tube) of the conveying trough, and matching the appropriate drive device and bearing system. This customized production mode ensures that the screw conveyor provided can accurately meet the performance requirements under specific working conditions, optimize material conveying efficiency, and improve the reliability and service life of the equipment.

Screw conveyor has many practical characteristics in industrial production due to its unique working principle and structural design. Its closed conveying method helps to reduce dust or leakage of materials during the transfer process, which is especially suitable for scenes where it is necessary to keep the environment clean or handle specific materials (such as those that are susceptible to moisture, volatile or have a certain odor). The equipment usually has a relatively simple mechanical structure, which makes it convenient in daily operation and maintenance. In addition, the screw conveyor shows good adaptability when handling a variety of material types. Whether it is dry powder, granules with a certain humidity, or small pieces of material of a specific size, they can be effectively transported by adjusting the screw parameters.