Telescopic belt conveyor

The price of telescopic belt conveyor varies depending on its length, width, load capacity, conveyor belt material, usually ranging from US$400 to US$7,500.

Power: 2.95KW 50HZ/60HZ

Width or diameter: 300mm

Voltage: 220V/380V/415V 3phase

Conveying speed: 20m/min/adjustable

Width: 800mm (standard)

Material: carbon steel/stainless steel/pvc/rubber

What is Telescopic belt conveyor?

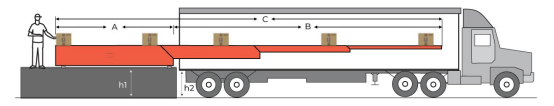

Telescopic belt conveyor is a common mechanical equipment in the field of material handling. Its core function is to realize horizontal, inclined or vertical transportation of bulk materials or finished items through continuous movement. The equipment has a retractable structure and can adjust the conveying length according to the operation requirements to meet the material transfer requirements in different scenarios. Its basic structure includes a frame, a conveyor belt, a drive device and a telescopic mechanism. The frame length is changed by hydraulic or electric means, and the conveyor belt automatically adapts to the length change through the belt storage device to ensure that the conveying surface always remains in a tensioned state.

What are the types of telescopic belt conveyors?

According to the structure and installation method, telescopic belt conveyors can be divided into two types: fixed and mobile. These two types have their own characteristics and are suitable for different industrial and logistics scenarios.

Fixed telescopic belt conveyorCarrying capacity and stability: Due to its fixed installation characteristics, fixed telescopic conveyors can usually be designed to withstand larger loads and have higher stability during operation.

Automation integration: Easy to integrate with existing production lines, automated warehousing systems or loading and unloading platforms to achieve continuous and automated material transportation.

The structure is usually more solid: In order to meet the needs of long-term and high-intensity operation, its frame and support structure are often more solid and durable.

High reliability: The stable installation foundation reduces vibration and displacement during operation, thereby improving the reliability and service life of the equipment.

Suitable for continuous operation: Suitable for places where the material entry and exit points are relatively fixed and require long-term continuous or high-frequency operation.

Precise positioning: Performs well in scenarios where materials need to be accurately transported to a fixed point.

Mobility: equipped with wheels (usually universal wheels or heavy-duty casters with brakes), it can be easily moved between different work areas. Some large mobile conveyors may even be equipped with power-driven travel mechanisms.

Flexibility: able to adapt to changing work needs and carry out loading, unloading or conveying operations in different locations.

Easy to operate: usually designed with simple movement and positioning mechanisms, which allows operators to quickly adjust the position of the equipment.

Compact structure: for easy movement, its structural design is often more compact.

Adapt to multi-point operation: suitable for places where the work location needs to be changed frequently or the site layout is not fixed.

What are the advantages of Telescopic belt conveyor?

With its unique telescopic ability and diversified functions, Telescopic belt conveyor has shown obvious advantages in improving logistics efficiency and optimizing the working environment.

Spatial adaptability: The outstanding advantage of Telescopic belt conveyor is its retractable characteristics. This enables the equipment to adjust the conveying length according to actual needs. When loading and unloading goods, it can extend into the depths of vehicles, containers or warehouses; and when it is not working or the operation is completed, it can be retracted, which greatly reduces the space occupied by the equipment.

Improve work efficiency: Through the telescopic function, the material delivery point can be directly extended to the inside of the loading and unloading area, thereby shortening the distance and time of manual handling.

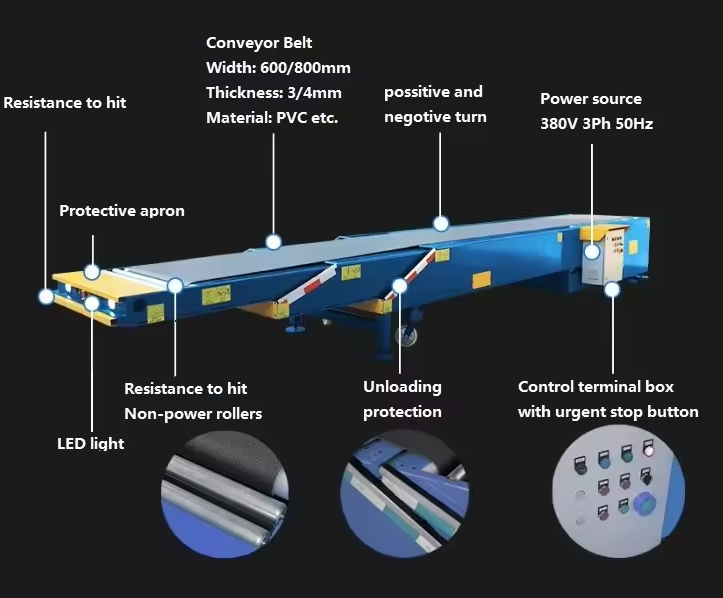

Wide range of material adaptability: Telescopic belt conveyor can smoothly convey various types of bulk or packaged materials, such as cartons, parcels, bagged items, small bulk goods, etc. As long as the size and weight of the material are within the load range of the equipment and are not particularly corrosive or high temperature, it can operate stably. By replacing conveyor belts of different materials (such as PVC, PU, rubber), it can also adapt to more specific environments and material delivery needs.

Flexibility and diversity: In addition to the basic telescopic function, modern telescopic belt conveyors often integrate a variety of additional functions to further enhance their application value. For example, the height lifting function enables it to adapt to loading and unloading platforms or production lines at different heights; the mobile design enables it to serve multiple operating points, improving the utilization rate of the equipment.

Telescopic belt conveyor parameters

| Type | Section Number | Fixed length (mm) – A | Extended Length (mm) – B | Total Length (mm) – C | Belt Width (mm) |

| ND-C-TBC-3S-5/7-800 | 3 | 5000 | 7000 | 12000 | 600/800 |

| ND-C-TBC-3S-5.4/6.6-800 | 5400 | 6600 | 12000 | 600/800 | |

| ND-C-TBC-3S-6/8.6-800 | 6000 | 8600 | 14600 | 600/800 | |

| ND-C-TBC-3S-4/5-800 | 4000 | 5000 | 9000 | 600/800 | |

| ND-C-TBC-3S-9.5/12-800 | 9500 | 12000 | 21500 | 600/800 | |

| ND-C-TBC-4S-5/10-800 | 4 | 5000 | 10000 | 15000 | 600/800 |

| ND-C-TBC-4S-6/12.6-800 | 6000 | 12600 | 18600 | 600/800 | |

| ND-C-TBC-4S-7/14.6-800 | 7000 | 14600 | 21600 | 600/800 | |

| SQ-XA-4-6/12.6-G | 6000 | 12600 | 18600 | 600/800 | |

| ND-C-TBC-4S-7/14.6-800 | 7000 | 14600 | 21600 | 600/800 | |

| ND-C-TBC-4S-7.5/16-800 | 7500 | 16000 | 23500 | 600/800 | |

| ND-C-TBC-5S-6/16-800 | 5 | 6000 | 16000 | 22000 | 600/800 |

| ND-C-TBC-5S-6/16-800 | 6000 | 16000 | 22000 | 600/800 | |

| ND-C-TBC-5S-7/17.5-800 | 7000 | 17500 | 24500 | 600/800 | |

| ND-C-TBC-5S-7.5/21-800 | 7500 | 21000 | 28500 | 600/800 | |

| ND-C-TBC-5S-10/20-800 | 10000 | 20000 | 30000 | 600/800 |

What is the working principle of Telescopic belt conveyor?

The telescopic belt conveyor consists of multiple functional modules, and its core components include the frame, conveyor belt, drive device, telescopic mechanism and control system. The frame is usually welded with high-strength steel to ensure the structural stability of the equipment when carrying materials; the conveyor belt, as a carrier for material carrying and transmission, is generally made of rubber, plastic or metal, and the surface can be configured with patterns or sidewall structures according to the characteristics of the material; the drive device mostly uses a combination of motor and reducer to drive the conveyor belt through a sprocket or roller; the telescopic mechanism is usually composed of a hydraulic cylinder, an electric push rod or a mechanical chain, which can achieve stepless adjustment of the conveyor length from several meters to tens of meters. The working principle of the equipment is based on the synergy of friction transmission and mechanical telescopic. When the drive device is started, the motor transmits the torque to the drive roller through the reducer, and the friction between the roller and the conveyor belt drives the belt body to circulate. The material is continuously transported to the specified position in the load-bearing section above the conveyor belt, and returns to the starting end through roller support in the return section. The telescopic mechanism changes the frame length by hydraulic or electric means. During the adjustment process, the conveyor belt automatically adapts to the length change through the belt storage device to ensure that the conveying surface always remains in a tensioned state.

What are the applications of Telescopic belt conveyor?

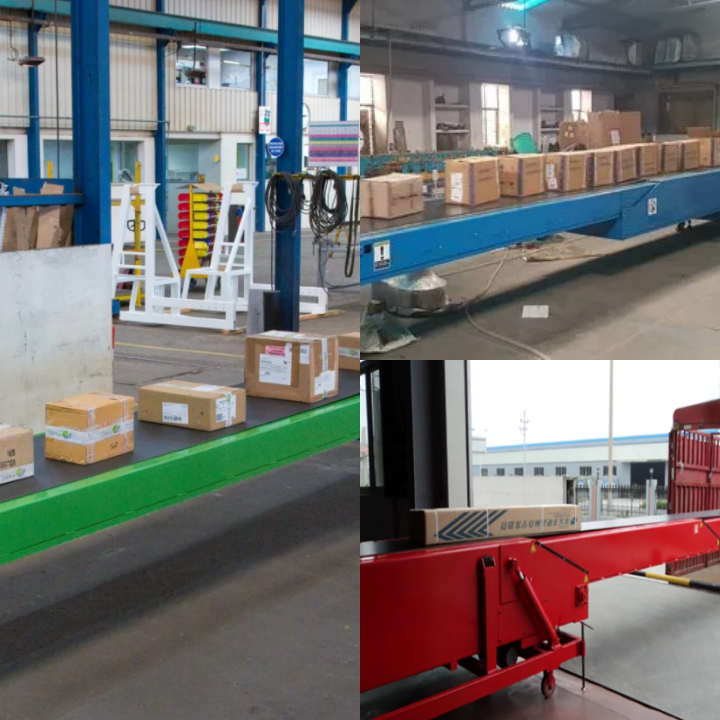

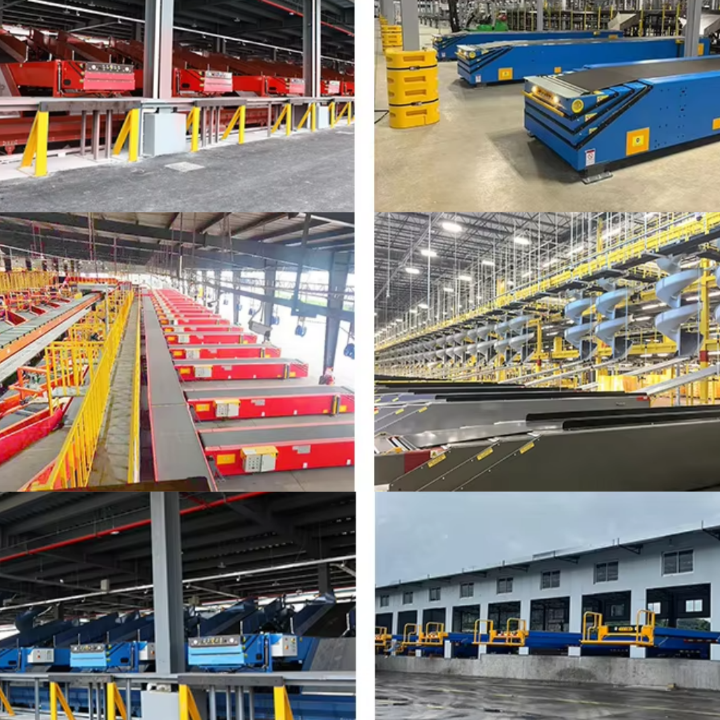

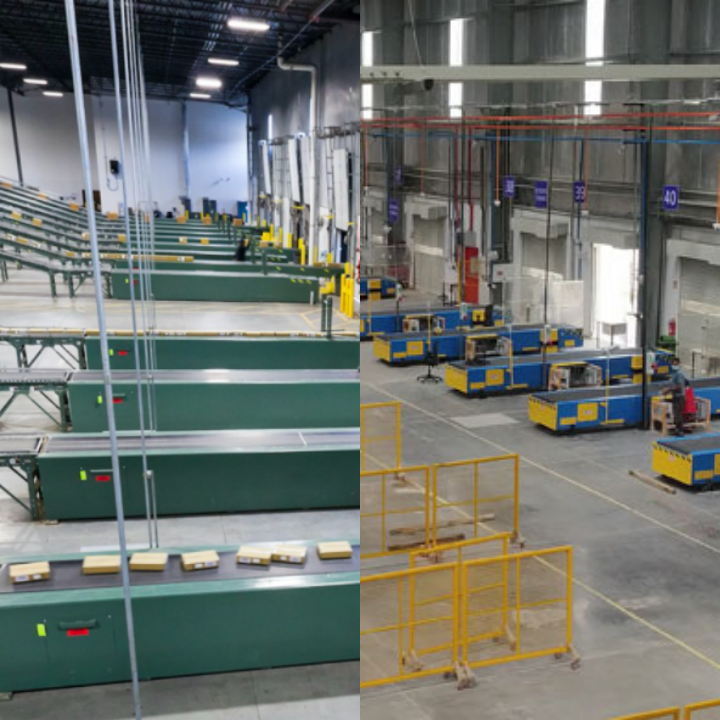

The application fields of telescopic belt conveyors cover logistics warehousing, port terminals, mining, grain processing and other industries. In the logistics distribution center, the equipment can be docked with the automated stereoscopic warehouse, and the goods can be quickly transferred between shelves of different heights through telescopic adjustment; in the bulk cargo loading and unloading operations at the port, the telescopic design enables the conveyor to adapt to the changes in the hatch position of ships of different tonnages, improving the loading efficiency; in underground mining, the equipment can adjust the length as the working face advances, reducing the secondary handling link; in the grain procurement link, the telescopic belt conveyor is used in conjunction with the grain unloading pit to realize the direct transportation of bulk grain from the transport vehicle to the grain storage warehouse. The e-commerce logistics park has improved the efficiency of parcel sorting by deploying telescopic belt conveyors, and the scalable characteristics of the equipment have improved the space utilization rate of the loading and unloading platform. In the cement production industry, the raw material conveying system adopts a multi-stage telescopic belt conveyor series solution to achieve continuous feeding from the raw material yard to the production workshop, and the system failure rate is reduced.

Telescopic belt conveyor case

Telescopic belt conveyor is a material conveying equipment with adjustable length. Its application scenarios are widely used in various operations that require material handling. Its core value lies in its ability to adapt to different operating distances and space restrictions to achieve smooth and continuous material transmission. Loading and unloading of materials is one of the core applications of Telescopic belt conveyor. This direct conveying method reduces the material transfer link and improves the efficiency of loading and unloading operations. Telescopic belt conveyor can be used as a connecting bridge between different production links or working areas. When the distance between two working points is not fixed or a temporary connection is required, it can provide a flexible conveying channel to ensure the smooth flow of materials. Due to its retractable characteristics, the Telescopic belt conveyor can be retracted when not in operation, occupying a small space. This is especially important for workplaces with limited site area or flexible adjustment of space layout. It allows the working area to be used for other activities or to store more materials when the conveying equipment is not in use. When materials need to be transported to multiple locations that are not fixed or need to be rotated, Telescopic belt conveyors, especially those with mobile functions, can flexibly switch between different work points. One device can meet the transportation needs of multiple areas, avoiding repeated investment in fixed equipment for each point. In general, Telescopic belt conveyors play an important role in various scenarios where materials need to be transported flexibly and labor-savingly.

What are the processes of telescopic belt conveyor?

The workflow of telescopic belt conveyor mainly revolves around its core functions, flexible length adjustment and material transportation. The whole process can be summarized as several key links: preparation and positioning, precise telescopic extension, material transmission and task closing. The first is preparation and positioning. Before each conveying operation begins, the operator needs to ensure that the equipment is in the correct position. If a mobile telescopic belt conveyor is used, it will be pushed to the tail of the truck, the container door or the designated loading and unloading area of the warehouse to ensure that it is aligned with the target point of the operation. For fixed equipment, this step is completed during the first installation. Next is precise telescopic extension and height adjustment. The telescopic section of the equipment will smoothly extend forward or retract backward until the front end of the conveyor belt reaches the loading or unloading point of the material accurately. For example, when loading goods, the conveyor belt will extend into the farthest end of the truck compartment to minimize the manual handling distance. If the equipment has a height lifting function, the operator will further adjust the height of the conveyor to keep it consistent with the height of the target platform or vehicle to ensure that the material can be transferred smoothly and smoothly to avoid impact or falling due to excessive drop. After positioning and adjustment, the belt begins to circulate. In loading mode, materials (such as cartons and packages) are placed at the rear end of the conveyor belt; in unloading mode, materials are picked up or slide down from the front end of the conveyor belt to the designated area. As the belt continues to run smoothly, materials are efficiently transported from the loading end to the unloading end. Operators can flexibly adjust the conveyor belt speed according to the type of material and the conveying volume to ensure the stability and efficiency of material transmission. Finally, the task is completed. When all materials have been conveyed or the task is completed, the conveyor belt must be stopped first. Then, the telescopic part of the conveyor is fully or partially retracted to restore it to a compact state, and the height lock is released to reset the height of the equipment. Disconnect the power connection and move it back to the designated parking area if it is a mobile device.

Telescopic belt conveyor manufacturers

In the field of telescopic belt conveyor manufacturing, different manufacturers have differences in product types and customization capabilities. Manufacturers can produce standardized telescopic belt conveyors. Such products usually have fixed conveying lengths, widths, load-bearing capacities, and limited functional configurations, such as common PVC belts, fixed speeds, and basic telescopic functions. Their advantages are short production cycles and relatively controllable costs. In addition, manufacturers can also provide more diverse product types. They may cover conveyor belts of different materials (such as PU food-grade belts, high-temperature resistant rubber belts), multiple drive modes (electric, manual), complex structural forms (such as multi-stage telescopic, with lifting functions), and special designs for specific industries or environments. At the same time, manufacturers have customization capabilities and can carry out in-depth design and manufacturing according to the specific needs of customers. For example, tailor-made for special material properties (such as extremely high temperatures and strong corrosiveness), unique site restrictions (such as narrow passages and large height differences), complex automation integration requirements (seamless connection with existing production lines, data transmission interfaces), or special requirements for equipment performance (such as ultra-long telescopic travel, ultra-high load-bearing capacity, and extremely high conveying speeds). This customization capability usually means higher investment and longer production cycle, but it can ensure that the equipment is highly compatible with the customer's actual application scenarios.

The technical advantages of telescopic belt conveyors are concentrated in their operational flexibility and environmental adaptability. The equipment can dynamically adjust the conveying length through a retractable structure. It can match shelves and transport vehicles of different sizes in logistics warehousing, adapt to the loading and unloading needs of various types of ships at ports and terminals, and can flexibly adjust with the progress of the working face in mining to reduce the material transfer link. Its operating stability is guaranteed by optimizing the spacing between rollers and controlling the tension of the conveyor belt, and it can maintain stable material transportation even at the maximum inclination angle.