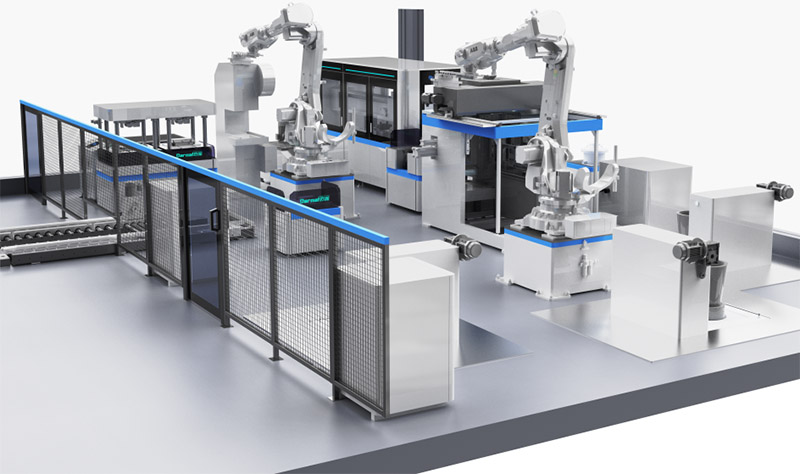

Intelligent gold electrolysis equipment

The gold refining process uses electrolysis technology, PLC intelligent control, data monitoring and other technologies to purify crude gold (purity ≥ 92%) to high-purity gold (≥ 99.99%)

Price: $500-$10,000

Refining capacity: 5-100KG

Model: JQ-JDJ-5, JQ-JDJ-10, JQ-JDJ-20, JQ-JDJ-30, JQ-JDJ-50

Power: 4-50kW

Looking for an advanced solution to purify gold with precision, safety, and speed? Our Intelligent Gold Electrolysis Equipment is a gold refining system that uses PLC automatic control. It purifies crude gold (≥92%) to above 99.99% through electrolysis. It can efficiently remove impurities (silver, copper, etc.) from gold, accurately control temperature and pressure, and monitor data intelligently. It can improve the purity and recovery rate of gold with minimal human intervention; the processing capacity can reach 5-100kg/day (multiple models are available), and it is suitable for gold refineries, jewelry processing, electronic gold plating and scrap metal recycling industries.

Why Choose Our Intelligent Gold Electrolysis System?

Intelligent gold electrolysis equipment adopts automatic electrolysis control system to achieve gold purification (purity ≥ 99.99%) and high-efficiency recovery, with the following core advantages:

Automated Electrolysis Control System: Equipped with PLC+HMI touchscreen interface for precise voltage and current control, allowing consistent refining quality and reduced energy waste.

High Purity Output (up to 99.99%): Removes copper, silver, nickel, and other impurities effectively while maximizing gold yield.

High recovery rate: Gold loss rate ≤ 0.02%, recovery rate over 99%, suitable for crude gold refining and electronic waste recycling.

Pollution-free: Built-in flue gas treatment system and acid recovery module, cyanide-free process, equipped with waste gas recovery system, ensuring the refining process is safer and more environmentally friendly.

Modular & Scalable Design: Available in 5kg, 10kg, 30kg, 50kg, and 100kg per batch configurations – suitable for both small workshops and industrial-scale plants.

Intelligent gold electrolysis equipment parameters

| Parameter | Value |

| Gold Purity | ≥99.99% |

| Processing Capacity | 50–500 kg/day (Customizable) |

| Energy Consumption | 0.8 kWh/kg (Industry-leading) |

| Automation Level | Fully Automated (PLC + HMI) |

| Dimensions | 4.2m x 2.5m x 3.1m (Compact Design) |

Application Industries

Intelligent gold electrolysis equipment has applications from mining to high purity electronics as follows:

Gold Refining Plants

Jewelry Manufacturers

Mining Companies

Precious Metal Recovery Units

Research Laboratories

Case Study: Transforming a Leading Refinery’s Operations

A Tier-1 gold refinery in South Africa achieved 40% higher monthly output and 15% lower operational costs after deploying our system. By integrating predictive maintenance and automated sludge management, their ROI surpassed expectations within 6 months.

Related news

- 2600 Degree Electromagnetic Vacuum Melting Furnace

- Gold extraction and refining equipment solutions

- Gold electrolysis machine

- Automatic gold refining equipment

- Gold purification system

- Smart gold refining technology

- Eco-friendly gold electrolysis