Food grade for stainless steel paddle mixer

Food grade for stainless steel paddle mixer is a mixing equipment designed and manufactured for the food processing industry. Its core function is to evenly mix various food raw materials

Applicable materials: liquid, powder, granule, slurry or paste

Material: food grade stainless steel (such as 304 or 316L)

Core component: paddle (single shaft or double shaft design)

What is a food grade for stainless steel paddle mixer

Food grade for stainless steel paddle mixer is a low-speed mixing equipment designed for the food industry. It is suitable for even mixing of powder, granule, paste or liquid food raw materials. The equipment is mainly composed of a U-shaped or cylindrical stainless steel container, a central stirring shaft, a paddle assembly, a drive system and a discharging device. The core stirring part adopts a paddle structure (such as anchor type, frame type, spiral ribbon type, etc.). During operation, the material is pushed by mechanical force to perform axial and radial compound motion in the container, thereby achieving a high uniformity mixing effect.

Food-grade stainless steel paddle mixers are widely used in production lines for condiments, dairy products, premixes and other products. They are key equipment to ensure the uniformity of food raw material mixing and the stability of product quality.

The difference between 304 stainless steel and 316 stainless steel

304 stainless steel: This is the most common and widely accepted food grade stainless steel. It contains 18% chromium and 8% nickel (or 10% nickel) and has excellent corrosion resistance, especially against acidic substances commonly found in many foods. It is durable, easy to clean and non-reactive, which means it will not leach harmful substances into food or change its taste.

316 stainless steel: Stronger corrosion resistance. It is particularly suitable for highly acidic or high-salt environments that may occur in some food processing applications. While 304 is usually sufficient, 316 provides additional protection and longer service life, especially in harsh conditions.

What are the classifications of food grade for stainless steel paddle mixers?

① Classification by stirring method

Forced stirring: The paddle is driven by a motor to force the material to flow and mix quickly in the mixing barrel. It has high stirring efficiency and good effect, and is suitable for stirring various materials.

Free-fall stirring: Relying on the gravity of the material itself, it falls freely and rolls in the mixing barrel to achieve material mixing. It is often used to stir some materials with good fluidity.

② Classification by stirring blade form

|

Stirring blade type |

Structural characteristics |

Applicable materials and mixing characteristics |

Common application scenarios |

|

Anchor blade |

Large diameter frame rotates against the wall, equipped with a scraper device |

Suitable for high viscosity, paste, and paste materials |

Jam, bean paste, batter |

|

Frame blade |

Similar to a rectangular frame, simple and durable |

Medium and low viscosity materials, moderate mixing speed |

Syrup, starch, seasoning powder |

|

Spiral blade |

Double spiral structure: inner belt pushes outside, outer belt pushes inside |

High mixing efficiency of powder or particles, uniform mixing |

Flour, premix, compound food powder |

|

Turbine Mixing paddle |

Multiple blades (oblique blades or flat blades) rotate at high speed |

High shear force, suitable for dispersion of liquid or light materials |

Food additive liquid, protein water, juice emulsification |

|

Paddle + scraper combination |

Central axis paddle + scraper structure |

Reduce cylinder wall residue and improve mixing efficiency |

Paste food, sauce, mixed paste |

|

Multi-layer composite paddle |

Multi-level staggered paddle structure |

Suitable for mixing multi-component materials with large specific gravity differences |

Nutritional powder, compound milk powder |

How does a food grade for stainless steel paddle mixer work

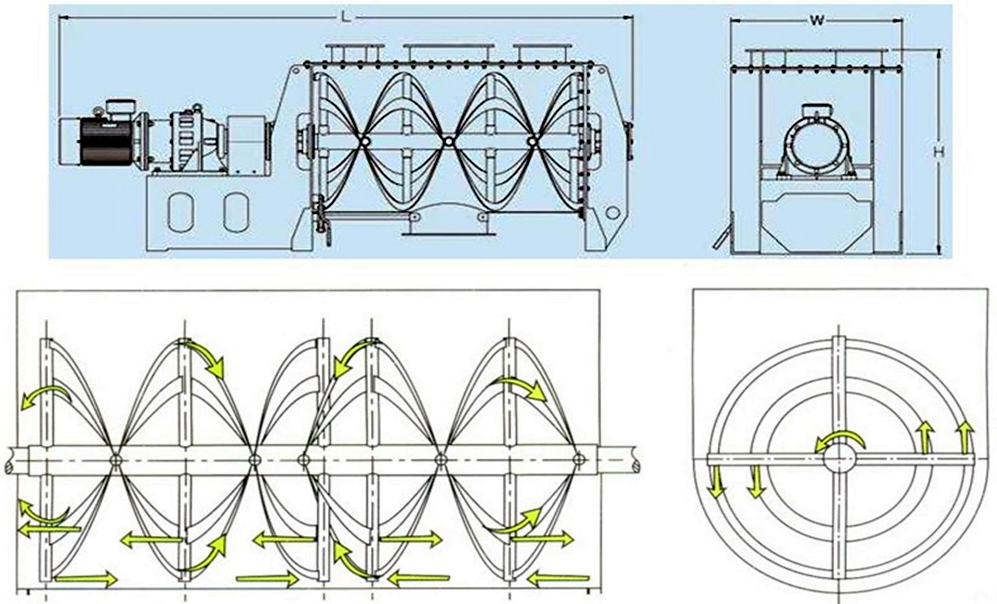

The working core of the paddle mixer lies in its internal paddle and rotating shaft. The food raw materials to be mixed (whether liquid, powder, granules, or a combination of them) are added to the mixing tank of the mixer. The power source of the mixer-the motor starts to run, driving the main shaft connected to the paddle to rotate. The paddle mounted on the main shaft rotates with the main shaft. These paddles are usually designed into specific shapes and angles (such as flat paddles, oblique paddles, frame paddles, anchor paddles, etc.) to meet the mixing needs of different materials.

During the rotation of the paddle, the material is sheared, pushed and rolled. The relative movement between the edge of the paddle and the material cuts and disperses the material. The shape and rotation direction of the paddle push the material from one area to another. The paddle stirs in the tank, so that the material is continuously brought from the bottom to the top and then falls back from the top, forming an overall convection cycle.

As the paddle continues to rotate, all the materials in the tank are repeatedly stirred, dispersed, and fused, and finally reach a state of uniform mixing. Whether it is solid and solid, liquid and liquid, or solid and liquid, the ideal mixing effect can be achieved in this way.

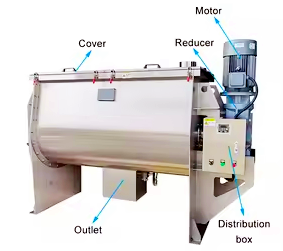

Structural composition of food grade for stainless steel paddle mixer

Tank: This is the main space for mixing materials, usually made of food grade stainless steel to ensure the safety and hygiene of the materials. The design of the container will take into account the need for easy cleaning and disinfection, and some designs may also include tilting or rotation functions to help empty the material.

Impeller/Agitator Blades: The paddle is one of the key components of the mixer, responsible for applying shear force, pushing force and other effects to the material to achieve uniform mixing of the material. Depending on the application requirements, the design shape and size of the paddles will vary greatly, such as straight blades, spiral blades, etc.

Drive System: Includes components such as motors and reducers to provide the required power for mixing. In order to adapt to the special requirements of the food industry, the motors usually need to have explosion-proof and waterproof functions, and the entire drive system must ensure smooth operation to avoid contamination of the materials.

Seal: A sealing device is installed at the position where the shaft passes through the container to prevent foreign matter from entering the container and prevent the material in the container from leaking, while also considering the convenience of cleaning.

Frame: Used to support the entire mixing equipment to ensure its stability and safety. The frame is generally also made of stainless steel to enhance corrosion resistance.

What are the advantages of food grade for stainless steel paddle mixers?

Smooth polished surface: Food-grade equipment must have a smooth, non-porous surface. This usually means electropolishing or high-grade mechanical polishing. This can minimize the risk of food particles adhering to the surface, prevent bacterial growth, and make cleaning and disinfection easier. Rough or concave surfaces are prone to breeding contaminants.

Efficient mixing: Paddle design (such as dual-shaft paddles) ensures uniform mixing of materials, suitable for powdered, granular or viscous materials, and improves production efficiency.

Durability and corrosion resistance: Materials and structures should be able to withstand regular cleaning cycles, disinfectants, and the abrasiveness of certain foods without corroding or degrading over time.

Versatility: The paddle shape and speed can be customized to adapt to different food processing needs (such as seasonings, milk powder, dough, etc.). Technical parameters of food grade for stainless steel paddle mixer

|

Model |

Effective volume (L) |

Total volume (L) |

Motor power (kW) |

Stirring speed (rpm) |

Material |

Dimensions (mm) |

|

JY-100 |

100 |

150 |

1.5 |

12–60 (variable frequency) |

SUS304 |

1100×700×900 |

|

JY-200 |

200 |

280 |

2.2 |

12–60 |

SUS304/316L |

1300×800×1100 |

|

JY-500 |

500 |

700 |

4.0 |

10–50 |

SUS304 |

1800×1 000×1300 |

|

JY-1000 |

1000 |

1400 |

5.5 |

10–45 |

SUS304 |

2200×1200×1500 |

|

JY-2000 |

2000 |

2600 |

7.5 |

10–30 |

SUS304/316L |

2800×1400×1800 |

|

JY-3000 |

3000 |

3800 |

11.0 |

8–25 |

SUS316L |

3200×1600×2000 |

Application of food grade for stainless steel paddle mixer

Food grade for stainless steel paddle mixer is widely used in all aspects of food production. In the baking industry, it mixes flour, yeast, oil and other raw materials into dough, and through stirring at different speeds, it fully forms gluten to provide a soft taste for bread and cakes; in the production of condiments, it can evenly mix peppers, spices, cooking oils, etc. to make chili sauce, salad dressing, etc., to ensure that every spoonful of sauce tastes the same. In beverage processing, the blender can fully mix concentrated juice, water, and additives to make bottled beverages taste uniform. At the same time, in dairy product production, it is used for raw material mixing and milk homogenization before yogurt fermentation to ensure the fine texture of the product.

In the meat processing field, the blender fully blends meat particles, starch, and seasonings by stirring meat fillings, enhancing the viscosity and elasticity of the meat fillings, and is used to make sausages, meatballs and other products. In the production of snack foods, the blender can mix grains, nuts, syrups, etc. to make oatmeal, energy bars and other products. In addition, in the process of candy making, the blender can also evenly mix syrups, pigments, and spices to make hard candies and soft candies of various flavors. Whether it is large-scale industrial production or small food workshops, food grade for stainless steel paddle mixers have become indispensable equipment for food processing due to their high efficiency, hygiene and durability.