Fully automated silver ingot refining

The electrolysis + melting and casting integrated technology can remove impurities such as copper and lead in silver and improve the purity of silver ingots.

Price: $1000-$110,000

Silver ingot purity: 99.9% ~ 99.99%

Power supply: Three-phase 380V, 50/60Hz

Capacity: 5-100KG

What is Fully Automated Silver Ingot Refining?

Fully automated silver ingot refining is a process that uses an intelligent system to achieve unmanned production of the entire process of silver from crude silver to high-purity delivery silver ingots (above 99.9%). The system integrates electrolytic purification, smelting, polishing, testing, coding, weighing and stacking. Without manual intervention, it can convert waste silver or ore into silver ingots with a purity of up to 99.99%. It improves production efficiency and reduces manual intervention, which can ensure the quality of silver ingots (reaching the national standard No. 1 silver standard), reduce workshop pollution and precious metal loss, and reduce the amount of silver occupied in the production process through high current density electrolysis (up to 1600A/m²).

End-to-End Automation: From melting to molded ingots – no manual handling.

AI-Powered Impurity Control: Real-time spectroscopy detects contaminants (e.g., Pb, Cu) with ≤50ppm tolerance.

Energy Efficiency: 25% lower power consumption vs. conventional furnaces.

Why Choose Fully Automated Silver Ingot Refining?

Fully automated silver ingot refining can realize intelligent operation of the entire process from raw material processing to finished product output, greatly reducing manpower input and human errors, accurately controlling refining parameters, and effectively improving the purity and quality stability of silver ingots.

Purity Guaranteed: Achieve ≥99.99% Ag purity through multi-stage electrolytic refining and centrifugal separation; AI adjusts chemical dosing (e.g., nitric acid) dynamically to minimize waste.

Zero Waste & Eco-Safe: Closed-loop filtration captures 100% airborne particles (OSHA compliant), Slag recycling converts residues into reusable alloys.

30% Higher Productivity: Robotic arms handle 2-ton/day capacity with <0.1% material loss; PLC-controlled smelting at 1,200–1,500K ensures uniform ingots

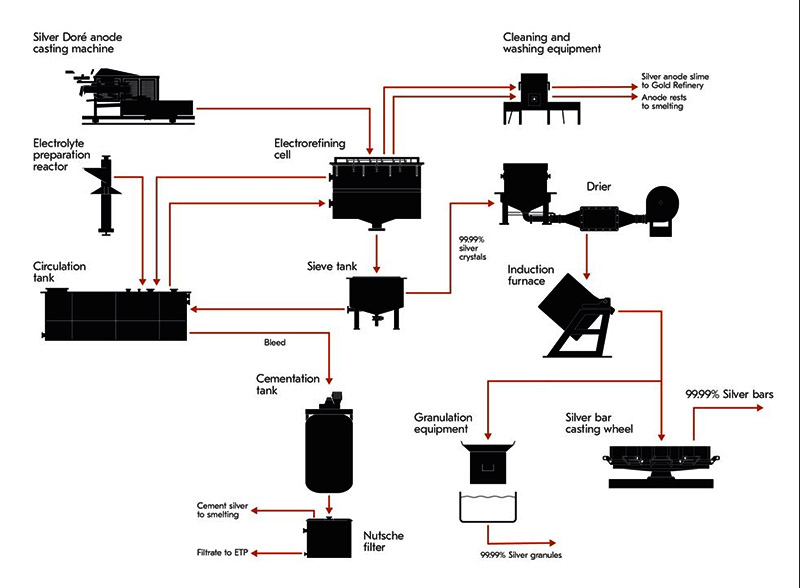

How Fully Automated Silver Ingot Refining Works?

The process of fully automated silver ingot refining includes raw material pretreatment, dissolution and refining, ingot casting, purity testing and other steps, as follows:

Pretreatment: Pretreatment of silver-containing raw materials, such as silver ore or crude silver, by crushing, grinding and other methods to make the particle size suitable for subsequent operations.

Electrolytic refining: Using gold-silver alloy (crude silver) as the anode, pure silver sheet, stainless steel plate or titanium sheet as the cathode, using an aqueous solution of silver nitrate and nitric acid as the electrolyte, under the action of direct current, the anode silver dissolves into the solution, and high-purity silver is precipitated on the cathode. During this period, the current density, electrolyte concentration and temperature and other parameters are precisely controlled. The silver precipitated on the cathode is then collected, and impurities and moisture are removed through steps such as cleaning and drying.

Ingot casting: The treated silver liquid is poured into a customized mold (1 kg to 10 kg) and cast into a silver ingot

Quality Assurance: Laser assay verifies purity; defective ingots auto-recycled.

What are the applications of fully automated silver ingot refining?

| Industry | Use Cases | Benefits |

| Jewelry Manufacturing | Recycling scrap into premium-grade silver | 99.99% purity for fine craftsmanship |

| Electronics Recycling | Recovering Ag from PCBs/switches | 98% yield from e-waste |

| Industrial Refineries | Large-scale bullion production | 2-ton/day throughput |

| Mining | On-site ore processing | Reduced transport costs |

Fully automated silver ingot refining case

Case Study: [ABC Precious Metals]

Challenge: Manual refining caused 15% material loss and inconsistent purity.

Solution: Deployed our PM-3000 Automated System.

Results: 99.992% purity achieved (LBMA certified); 40% lower labor costs with 24/7 operation.

How to Select the Right Fully automated silver ingot refining?

Capacity: Choose 50kg–5T/day models based on volume.

Purity Requirements: Opt for ≥99.99% if supplying LBMA markets.

Energy Source: Electric (cleaner) vs. gas (lower upfront cost).

Automation Level: Robotic integration vs. semi-automated.

After-Sales Support: Look for remote monitoring & 24/7 tech aid8.