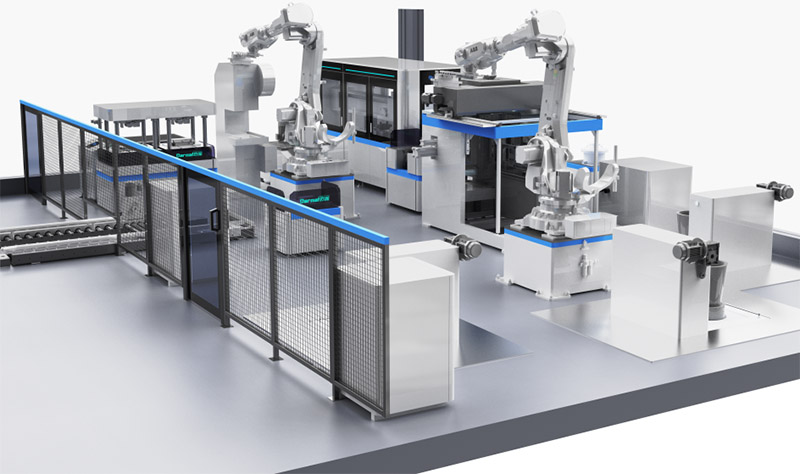

Precious metal refining equipment

It can remove impurities and purify rare metals such as gold, silver, platinum, palladium, etc., and the purification rate can reach 99%.

Price: $800-$140,000

Melting temperature: 600℃-2600℃

Capacity: 0-100kg (customizable)

Power: 20KW-120KW,380V

What is Precious metal refining equipment?

Precious metal refining equipment is used to purify precious metals such as gold, silver, platinum, palladium, etc. from scrap, electronic waste, jewelry and industrial by-products. It removes impurities in precious metals through chemical methods (such as electrolytic refining) or physical methods (such as vacuum distillation) to improve the purity of metals. The purity reaches more than 99.9%, making it meet industrial or financial transaction standards.

✔ Fully Automated & Semi-Automatic Systems

✔ Some equipment (such as Hastelloy alloy furnace) adopts low temperature refining technology to reduce energy consumption and reduce pollution emissions.

✔ Compact & Scalable Solutions (Lab-Scale to Industrial)

Why Choose Our Precious metal refining equipment?

Precious metal refining equipment has outstanding refining capabilities in purifying rare metals such as gold, silver, platinum, and palladium. For example, chemical refining can make the purity of gold and silver reach 99.99%, and the recovery rate exceeds 99.9%; the Hastelloy alloy furnace adopts low-temperature refining technology, which reduces energy consumption and pollution emissions compared with traditional fire methods, and the vacuum induction melting furnace saves more than 60% energy. It has a high degree of automation, and the PLC control system realizes precise temperature control and full process automation, reduces manual intervention, and improves production efficiency. The equipment has strong adaptability and can process raw materials in different forms, such as gold mud, alloy waste, etc., and supports customized production.

| Feature | Benefit |

| High Purity Output (99.95%+) | Maximize metal value with near-perfect refining. |

| Low Chemical Consumption | Saves costs & reduces hazardous waste. |

| Fast Processing Time | 50% faster than traditional methods. |

| Modular Design | Expandable for growing refining needs. |

| Zero Smelting Required | Safe, non-thermal chemical extraction. |

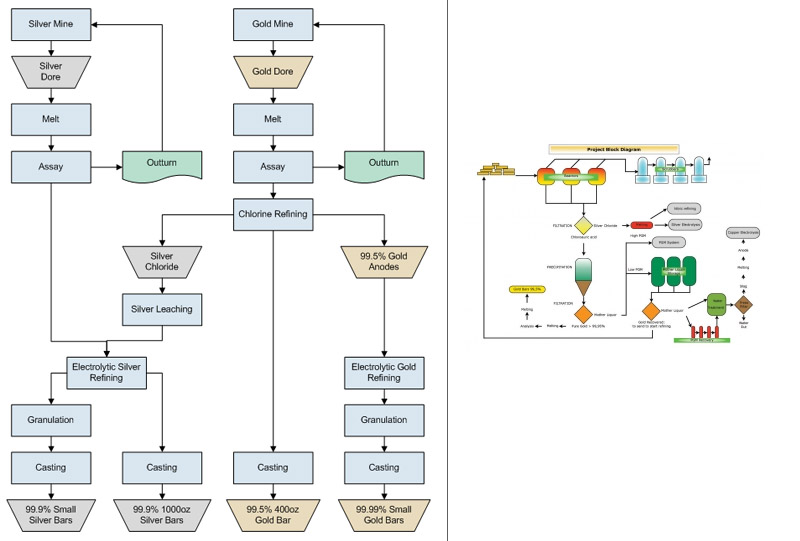

What is the process flow of Precious metal refining equipment?

Precious metal refining equipmentThe process of purifying precious metals includes dissolution, filtration, precipitation, smelting and casting. Understanding the process will help us better choose equipment. The specific steps are as follows:

Dissolution: The raw metal is dissolved in high purity acid (Aqua Regia, Cyanide-Free).

Filtration: Impurities are removed from the metal using a filter press or filter press

Precipitation: Selective chemical agents isolate target metals.

Electrolysis/Cementation: Further purification via electrochemical methods.

Melting & Casting (Optional): Produces bars, grains, or custom shapes.

Precious metal refining equipment parameters

| Equipment type | Maximum temperature | Capacity | Power | Applicable metals |

| Vacuum distillation furnace | 1600℃ | 50kg | 120KW | Gold, silver, copper |

| Vacuum induction melting furnace | 1700℃ | 10kg | 70KW | Nickel-based alloy, rare earth |

| Infrared melting furnace | 2600℃ | Customizable | - | Platinum, gold |

| Hydrogenation reduction purification furnace | 600℃ | Multi-layer tray | 35KW | Platinum, palladium, rhodium and other platinum group metals |

Applications – Who uses our Precious metal refining equipment?

Precious metal refining equipment can be used for the recovery and purification of precious metals in electronic waste, jewelry manufacturers, mining, metallurgy, chemical industry, scientific research, automobile and other industries.

Electronic waste recycling: Recover valuable precious metals from scrap electronic products.

Jewelry manufacturers: Refine scrap gold/silver for reuse.

Mining and metallurgy: Extract and refine gold, silver, platinum group metals, etc. from precious metal ores.

Chemical and pharmaceutical industries: Recover and purify precious metals used as catalysts or other purposes.

Scientific research and laboratories: For the preparation and research of high-purity precious metals.

Automotive catalyst recycling: Recover precious metals such as platinum, palladium, rhodium, etc. from scrap automotive catalysts.

Dental and medical: Recover platinum/palladium from industrial waste.

Precious metal refining equipment customer case

A European electronic recycling plant wants to use Precious metal refining equipment to recover gold from electronic waste

Challenge: Needed high-yield gold extraction from discarded circuit boards.

Solution:

✔ Installed PMR-500 system (Chemical + Electrolysis)

✔Output: 99.97% pure gold

✔ Recovery Rate: 98% (vs. 85% with traditional methods)

A large gold mining company uses our electrolytic refining equipment to increase the purity of crude gold from 90% to 99.99%, greatly improving product value and market competitiveness.

An electronic waste recycling company introduced our chemical refining system and successfully recovered gold and silver from waste mobile phone circuit boards, achieving a win-win situation of resource reuse and economic benefits.

A well-known jewelry manufacturer uses our small precious metal refining equipment to realize the self-recycling and purification of scraps generated during the production process, reducing the cost of raw materials.