Analytic Sieve

Analytic Sieve is a tool for measuring particle sizes, which can rapidly and effectively determine the dimensions of solid particles ranging from 125 mm down to 20 μm.

Diameter:75mm, 100mm, 200mm, 300mm, 400mm

Measuring range:20µm-125mm

Feeding amount:200g

layer:1-8 layers

Power:0.125KW

What is Analytic Sieve?

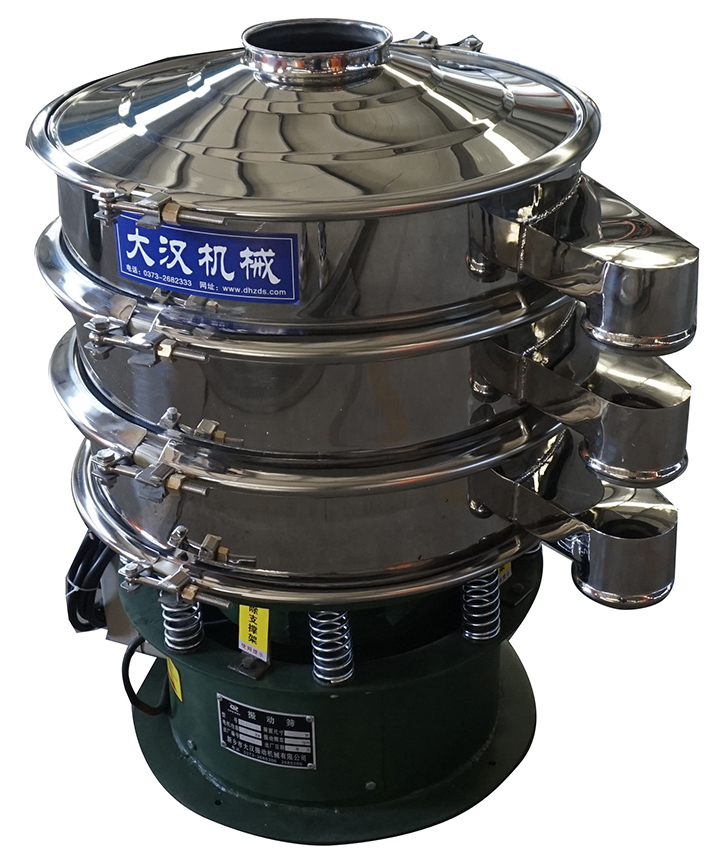

Analytic Sieve, named for its precise particle size analysis capability, is a laboratory screening device integrating multi-layer sieve frames and a controllable vibration system. Featuring a modular design, it uses electromagnetic drives or speed-controlled motors as power sources, paired with internationally certified sieves (e.g., ISO 3310), enabling high-precision grading from coarse particles to nano-level powders. Typical models like the AS-200 series support 1-8 layers of sieve frames, with screening areas ranging from 0.03 to 0.15 m², suitable for 5-200g samples to meet laboratory-grade particle size analysis needs in pharmaceuticals, materials, food, and other fields. It delivers consistent, repeatable results, linking lab research to industrial quality standards seamlessly.

What are the Core Advantages of Analytic Sieve?

Analytic Sieve stands out for its exceptional performance, regulatory compliance, and user-friendly design, making it an indispensable tool for precise particle analysis. Its ability to balance accuracy and efficiency ensures reliable data across small-batch testing and routine quality checks.High efficiency & precision: Screening efficiency increases by 80% compared to manual methods, with errors ≤3%. Teflon-coated sieves solve agglomeration problems of sticky materials.

Compliance & durability: 304 stainless steel meets GMP standards. Sieves are compatible with international certifications like ISO 3310, supporting customization of titanium/nylon meshes.

Intelligence & convenience: One-key start/stop + automatic timing, 5-minute quick sieve replacement, noise ≤60dB, vibration attenuation rate 80%.

How does the Grading System of Analytic Sieve work?

Coarse grading (4-60 mesh): Suitable for primary screening of ores, grain impurity removal, etc.

Medium grading (60-325 mesh): Commonly used for particle size detection of building materials (e.g., cement, quartz sand).

Fine grading (325-2000 mesh): Specifically designed for nanomaterials, catalysts, etc.

What is the Working Principle of Analytic Sieve?

Technical Parameters of Sieve Analysis Test

| No. | Technical | Technical indicate |

| 1 | Sieve Diameter | 200mm 8inch/300mm 12inch |

| 450mm 18inch/100mm4inch/75mm 3inch | ||

| 2 | Material | Stainless steel or Brass |

| 3 | Inner height | 50mm and 60mm |

| 4 | Aperture size range | 0.02mm to 125mm |

| 5 | Hole model | Wire mesh and perforated plate |

| 6 | Detail aperture | 125, 106, 100, 90, 75, 63, 53, 50, 45, 37.5, 31.5, 25, 22.4, 19, 16, 13.2, 12.5, 11.2, 9.5, 8, 6.7, 6.3, 5.6, 4.75, 4, 3.35, 2.8, 2.36, 2, 1.7, 1.4, 1.18, 1, 0.85, 0.71, 0.6, 0.5, 0.425, 0.355, 0.3, 0.25, 0.212, 0.18, 0.15, 0.125, 0.106, 0.09, 0.075, 0.063, 0.053, 0.045, 0.038mm etc. |

| 7 | Use | Grading Standard Testing Sieve Test Sieve for soil test sieve, aggregate sieve, concrete test sieve, cement test sieve, asphalt test sieve, wet sieve, wire mesh sieve, perforated sieve, astm sieve, en sieve |

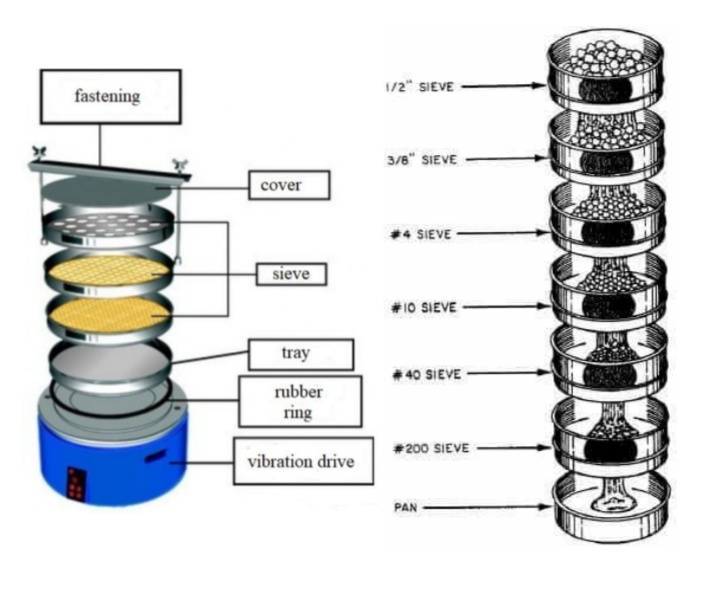

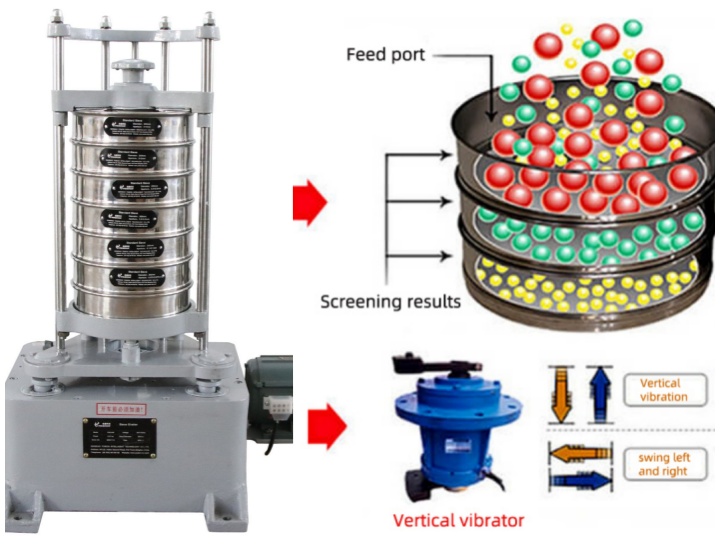

The device achieves material grading through high-frequency vibration of sieve meshes driven by a vibration source:

Power transmission: Electromagnetic vibrators or speed-controlled motors drive eccentric blocks to rotate, generating 3D vibrations (vertical ejection + horizontal displacement) with a frequency of 50-300Hz and amplitude of 0.1-2mm.

Material screening: After samples are added to the top sieve frame, particles smaller than the sieve aperture pass through to the lower layer under the combined action of vibration and gravity, while larger particles remain until discharged from the outlet.

Data generation: After screening, the mass of residues on each layer is weighed, and particle size distribution curves (e.g., D10, D50, D90) are automatically generated based on sieve aperture parameters, with errors controlled within ±3%.

Where is Analytic Sieve applied?

With its versatile functionality, Analytic Sieve plays a crucial role across diverse industries, ensuring quality control and facilitating scientific research. It adapts to both strict regulatory demands (like pharmaceutical GMP) and flexible R&D needs in new material development.Pharmaceuticals: API particle size control (e.g., aspirin D50=10-50μm), excipient screening (magnesium stearate ≤2% residue on 200 mesh).

Food industry: Flour ≤5% residue on 80 mesh (GB/T 5507), nut powder 100 mesh control for smooth texture.

Materials science: Lithium battery cathode materials (lithium iron phosphate D50=10-20μm), ceramic powder sintering optimization.

Chemical/mining: Catalyst grading (45-75μm), copper ore -75μm particle ratio correlation with flotation efficiency.

What does a sieve analysis report include?

Sieve analysis results show a granular material’s particle size distribution, helping verify if it meets production needs. Key information includes:Mass retained on individual sieves: Weight of material left on each sieve (in grams/ounces). It reflects the proportion of particles larger than the sieve’s mesh—e.g., more mass on a 20-mesh sieve means more coarse particles above 20 mesh.

Cumulative retained mass: Total weight of material retained from the top sieve down to a specific one. It shows the total amount of particles larger than that sieve’s size.

Cumulative retained percentage: Ratio of cumulative retained mass to the initial sample mass (×100%). It indicates the share of coarse particles, aiding cross-comparisons—e.g., 30% at 50 mesh means more coarse particles than 20% in another sample.

Cumulative passing percentage: 100% minus cumulative retained percentage, showing particles smaller than the sieve’s mesh. For example, 60% passing 80 mesh means 60% of particles are finer than 80 mesh.

Particle size distribution curve: A graph plotting sieve size (mm/μm) against cumulative percentages. A steep curve means narrow size range; a flat one indicates wider distribution, visualizing uniformity.

As a hub for particle size analysis connecting laboratory research and industrial applications, Analytic Sieve features "precise grading, data controllability, and compliance adaptability". From micron-level regulation in pharmaceutical formulations to nano-level exploration in new material R&D, its modular design and intelligent control system continue to empower scientific innovation and quality management. In the future, with AI algorithm optimization for screening parameters and cloud data management integration, Analytic Sieve will further break through the boundary of a "tool" to become a key link in laboratory digital transformation.